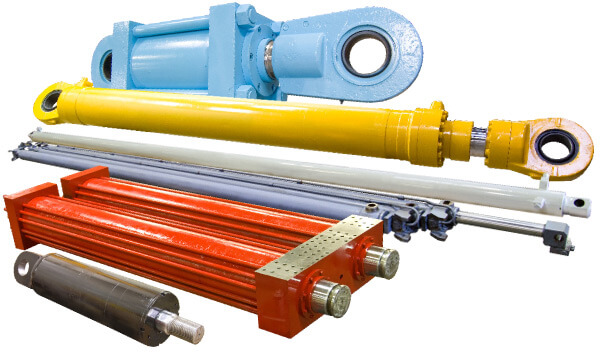

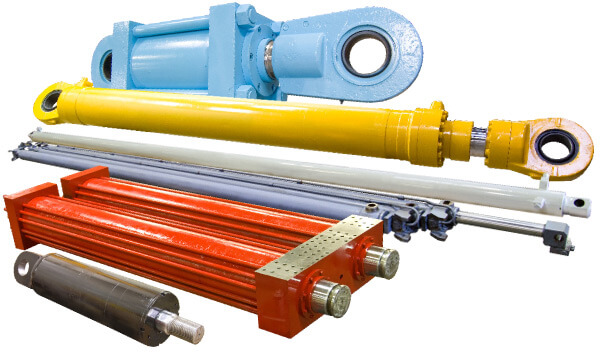

Product Description

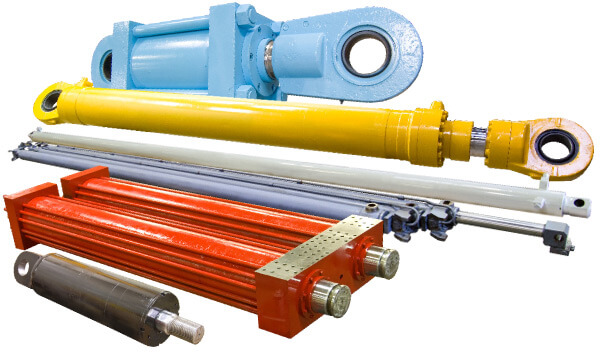

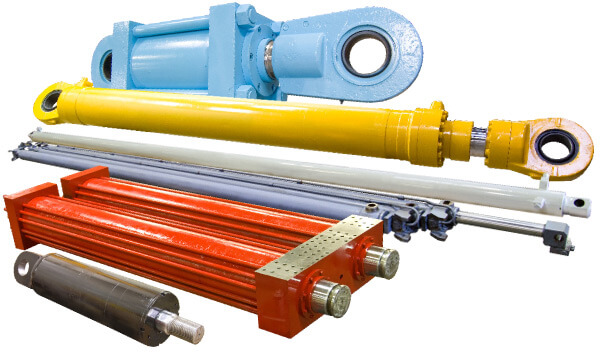

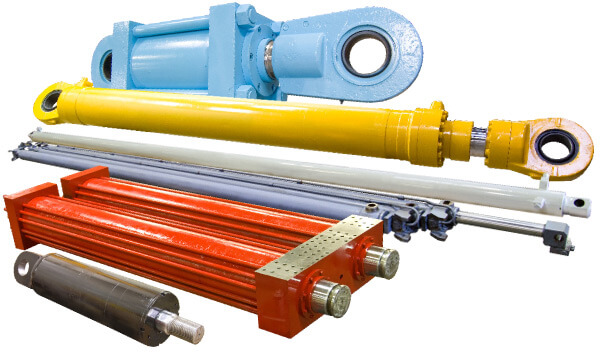

Products Description

|

Product Name |

HSG Series Hydraulic Cylinder |

|||

|

Work Press |

7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

|||

|

Material |

Aluminum,Cast Iron,45mnb Steel,Stainless Steel |

|||

|

Bore Size |

40mm–320mm,Customizable |

|||

|

Shaft Diameter |

20mm–220mm,Customizable |

|||

|

Stroke Length |

30mm–14100mm,Customizable |

|||

|

Rod Surface Hardness |

HRC48-54 |

|||

|

Paint Color |

Black,Yellow,Blue,Brown,Customizable |

|||

|

Mounting |

Earring,Flange,Clevis.Foot,Trunnion,Customizable |

|||

|

Warrenty |

1 Year |

|||

|

MOQ |

1 Piece |

|||

|

Delivery Time |

7-15 Days,Also depands on specific demands |

|||

|

Certification |

ISO9001,CE |

|||

Company Profile

QIANGLIN HYDRAULIC MACHINERY CO., LTD

| QiangLin is a professional hydraulic equipment manufacturer, mainly engaged in hydraulic system design, manufacture, installation, transformation, sales, and technical services. Our manufacturing facilities are certified to the ISO 9001 standard. We are an approved supplier to many equipment manufacturers in China. We are also partners with many customers from America, Canada, Australia, Germany, England, and other European Countries. Product quality, shorter delivery time, and customer satisfaction are our long-term commitments to our CHINAMFG customers. Hope to be your partner. |

FAQ:

Q1: Are you a trading company or a manufacturer?

A: We have our own factory.

Q2: Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, 15-30 working days if we don’t. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What are your After-sales services?

A: Before shipment, Each individual product will be strictly inspected on our factory QC Process

System. In addition, We have a

Customer Service team to respond to customers’ questions within 12 hours. Being helpful in

solving customers’ problems is always our goal. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lift cylinders be used in hydraulic vehicle lifts?

Yes, lift cylinders are commonly used in hydraulic vehicle lifts. Here’s an explanation of their utilization in hydraulic vehicle lifts:

Hydraulic vehicle lifts are devices used to raise vehicles for maintenance, repairs, or storage purposes. Lift cylinders play a crucial role in the lifting operation of these hydraulic lifts.

In hydraulic vehicle lifts, lift cylinders are typically positioned vertically and connected to the lifting platform or arms. The lift cylinders work by converting hydraulic pressure into mechanical force, allowing the platform or arms to lift the vehicle. When the hydraulic system is activated, the hydraulic fluid is pressurized, and it flows into the lift cylinders. The force exerted by the pressurized fluid causes the lift cylinders to extend, resulting in the upward movement of the lifting platform or arms.

Lift cylinders used in hydraulic vehicle lifts are usually hydraulic cylinders. Hydraulic systems offer the advantages of smooth operation, precise control, and high lifting capacities. The hydraulic system includes a pump, control valves, hydraulic lines, and the lift cylinders. By controlling the flow of hydraulic fluid to the lift cylinders, operators can easily adjust the lifting height and position of the vehicle.

One of the key benefits of using lift cylinders in hydraulic vehicle lifts is their ability to provide stable and controlled lifting. The lift cylinders are designed to handle the weight of vehicles and ensure safe and secure lifting. They offer reliable support and stability throughout the lifting process, allowing technicians to work on vehicles with confidence.

In addition to lifting capabilities, lift cylinders in hydraulic vehicle lifts may incorporate safety features such as locking mechanisms or overload protection. These safety measures enhance the overall performance and reliability of the lifts, ensuring the safety of both the vehicle and the operators.

Overall, lift cylinders are integral components in hydraulic vehicle lifts, enabling the vertical lifting motion and providing stability during vehicle maintenance and repair operations. Their hydraulic operation, strength, and safety features make them essential for efficient and safe vehicle lifting.

How does a lift cylinder handle variations in cylinder stroke length?

A lift cylinder is designed to handle variations in cylinder stroke length through its adjustable rod or piston. The stroke length refers to the distance the cylinder can extend or retract, and it can be adjusted to meet specific requirements in different applications.

In hydraulic lift cylinders, the stroke length can be modified by adjusting the position of the rod or piston within the cylinder. This adjustment is typically achieved by adding or removing spacers or by using adjustable stops. By changing the effective length of the cylinder, the stroke can be increased or decreased accordingly.

The adjustment of the stroke length allows the lift cylinder to accommodate different operational needs. For example, in material handling applications, where varying load sizes are encountered, the stroke length can be adjusted to ensure that the cylinder extends or retracts precisely to the required position. This flexibility enables the lift cylinder to handle a wide range of loads and adapt to different lifting or pushing scenarios.

In addition to adjusting the stroke length, lift cylinders often incorporate position feedback mechanisms. These mechanisms, such as linear transducers or position sensors, provide real-time feedback on the actual position of the cylinder. By monitoring the position, the control system can ensure accurate and precise control over the cylinder’s movement, regardless of the stroke length.

The ability to handle variations in cylinder stroke length is crucial in many industrial applications. It allows for adaptability, efficiency, and improved performance in tasks such as material handling, assembly, and automation. By adjusting the stroke length, lift cylinders can optimize their operation, ensuring that the required force and movement are achieved consistently.

In summary, lift cylinders handle variations in cylinder stroke length through adjustable rods or pistons. This adjustment capability, combined with position feedback mechanisms, enables precise control and adaptability in different applications. By accommodating different stroke lengths, lift cylinders can effectively meet the specific requirements of a wide range of industrial tasks.

How does a lift cylinder differ from other types of hydraulic cylinders?

A lift cylinder, also known as a hydraulic lift cylinder or hydraulic lifting cylinder, has some distinct characteristics that set it apart from other types of hydraulic cylinders. Here’s an explanation of how a lift cylinder differs from other hydraulic cylinders:

While hydraulic cylinders come in various types and designs, including single-acting, double-acting, telescopic, and differential, a lift cylinder typically refers to a double-acting cylinder. Here are some key differences:

1. Double-Acting Design:

A lift cylinder is generally designed as a double-acting cylinder, meaning it can generate force in both the extension and retraction strokes. This allows for bidirectional movement and greater flexibility in lifting and lowering operations. In contrast, some other types of hydraulic cylinders, such as single-acting cylinders, generate force in only one direction.

2. Linear Motion:

The primary function of a lift cylinder is to provide linear motion for lifting and lowering loads. It is specifically designed to generate vertical movement, making it suitable for applications that require vertical displacement, such as hydraulic lifts, scissor lifts, and elevating platforms.

3. Load Capacity:

Due to their design and intended use, lift cylinders are typically designed to handle heavier loads compared to other types of hydraulic cylinders. They are engineered to provide high lifting capacities and withstand the forces associated with lifting heavy objects.

4. Control Valve Configuration:

Lift cylinders often require specialized control valve configurations to regulate their operation. This is because precise control is crucial in lifting and lowering operations, especially in applications where safety and accuracy are paramount, such as in hydraulic lifts or elevators.

5. Application-Specific:

While other types of hydraulic cylinders have diverse applications across various industries, lift cylinders are commonly used in specific applications that require vertical lifting and lowering. They are frequently employed in hydraulic lifts, scissor lifts, material handling equipment, and other vertical motion systems.

6. Construction and Mounting:

Lift cylinders may have specific construction features and mounting options to accommodate their application requirements. For example, they may include features like safety locks, cushioning mechanisms, or specialized mounting brackets to ensure secure and efficient operation in lifting applications.

In summary, a lift cylinder differs from other types of hydraulic cylinders in terms of its double-acting design, focus on linear motion for lifting and lowering, higher load capacity, specialized control valve configuration, application-specific usage, and construction features tailored for lifting applications. These distinctions make lift cylinders well-suited for vertical motion systems and applications that require reliable and precise lifting operations.

editor by Dream 2024-05-09

China Best Sales Telescopic Single Acting Hydraulic Oil Cylinder Car Lift vacuum pump oil

Product Description

Single acting telescopic hydraulic oil cylinder for dump truck

Product Description

Hyva & CHINAMFG & Custom hoist & Xihu (West Lake) Dis.r type hydraulic telescopic Cylinders are used for Dump Truck, Tipper Truck, Trailer, Agricultural Machinery, Garbage Truck, Landing Platform etc.

Tsingshi hydraulic Customers, MAN, JAC, VOLVO, SHACMAN, DAF, JMC, HUNO, CIMC, SINOTRUK, TATRA,BENS,XIHU (WEST LAKE) DIS.FENG, FOTON,etc.

1.Each stage electroplate hard chrome;

2.lighter and easier to maintenance hydraulic telescopic cylinder;

3.High quality alloy seamless steel pipe have better mechanical properties;

4.The world famous brands of seals, such as HALLITE, PARKER,etc;

5.World-class processing technology ensures stable and reliable quality.

| NO | ITEM | DATA OF dump truck hydraulic cylinder |

| 1 | Material | Carbon Steel, Alloy Steel, 27SiMn,45#,20#,etc |

| 2 | Honed tube | 40-300mm, Heat treatment, honing, rolling |

| 3 | Honed tube | 30-280mm, plated nickel or hard Chrome or ceramic |

| 4 | Seal kit | Parker, Merkel, Hallite, Kaden, etc |

| 5 | Coating | Sandblasting, primer paint, middle paint, finish paint, Color can paint according to customer demands. |

| 6 | Technology | Parker,custom hoist, hyco,HYVA, Meiller

SAT,DAT |

| 7 | Mounting type | Pin-eye , flange, trunnion mount,ball mount, screw thread. FC, FE, FEE, FSE,TPIN |

| 8 | Working medium | Hydraulic Oil |

| 9 | Working pressure | 16-20Mpa telescopic hydraulic cylinder |

| 10 | Temperature range | -50°C to +100°C |

Detailed Photos

Company Profile

Tsingshi hydraulic is a hydraulic telescopic cylinder for dump tipper truck company which takes up with hydraulic design, R&D, manufacturer, sell and service hydraulic products-Telescopic hydraulic cylinder for dump truck.

-Hydraulic Cylinders Certification ISO9001 TS16949, etc;

-Telescopic jack Hydraulic Cylinder Export to North America, South America, Australia, South Korea, Southeast Asia, South Africa, Europe, Middle East, etc;

-ODM&OEM Single acting Hydraulic Telescopic Cylinder according to client’s requirements;

-Professional manufacturer& supplier of Hydraulic Cylinders over 30 years;

-The Hydraulic telescopic Cylinders can be used for Dump Truck, Tipper Truck, Trailer, Agricultural Machinery, Garbage Truck,Landing Platform etc; We can produce the follow brand hydraulic cylinder. HYVA, BINOTTO, EDBRO, PENTA, MAILHOT, CUSTOM HOIST, MUNCIE, METARIS, HYDRAULEX GLOBAL, HYCO, PARKER, COMMERCIAL HYDRAULICS, MEILLER. WTJX, XT, JX, HCIC, ZX, SZ, SJ.

CUSTOMERS PHOTOS

QUALITY GUARANTEE

HIGH QUALITITY GUARANTEE-Telescopic hydraulic cylinder for dump truck

-7*24 service.

-Competitive price.

-Professional technical team.

-Perfect after-sales service system.

-ODM&OEM according to customer needs.

-Strong production capacity to ensure fast delivery.

-Guarantee Quality. Every process must be inspected, all products need be tested before leaving the factory.

<Hydraulic Cylinder Leak Test

<Telescopic Hydraulic jack Buffer Test

<Hydraulic Telescopic Cylinder Reliability Test

<Dump truck Hydraulic Cylinder Full Stroke Test

<Dump trailer Hydraulic Cylinder Trial Operation Test

<Tipper truck Cylinder Pressure Tight Test

<Dump truck telescopic Hydraulic Cylinder Load Efficiency Test

<Dump trailer telescopic Hydraulic Cylinder Start-up Pressure Test

<Long stroke single acting hydraulic telescopic cylinder Testing the Effect of Limit

SALES AND SERVICE

ONE WORLD ONE LOVE

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO/Ts16949 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What are the advantages of using lift cylinders in material handling?

Using lift cylinders in material handling offers several advantages that enhance efficiency, productivity, and safety. Here are some key advantages of using lift cylinders:

1. Lifting Capacity:

Lift cylinders are designed to provide substantial lifting capacity. They can handle heavy loads and are available in various sizes and configurations to accommodate different weight requirements. This allows for efficient lifting and moving of materials, reducing the need for manual labor or multiple lifting mechanisms.

2. Precise Control:

Lift cylinders offer precise control over the lifting and lowering operations. By regulating the flow and pressure of hydraulic fluid, operators can achieve accurate positioning and controlled movements. This level of control ensures safe and precise material handling, preventing damage to the load and the surrounding environment.

3. Smooth and Stable Operation:

Lift cylinders provide smooth and stable operation during lifting and lowering processes. The hydraulic system minimizes jerking or sudden movements, ensuring a controlled and stable lifting experience. This stability is crucial when handling fragile or delicate materials that require careful maneuvering.

4. Flexibility:

Lift cylinders offer flexibility in terms of their application and adaptability to different material handling scenarios. They can be integrated into various types of equipment, such as forklifts, cranes, or material handling platforms. This versatility allows for efficient material handling across different industries and environments.

5. Space Efficiency:

Compared to other lifting mechanisms, lift cylinders are relatively compact, which makes them suitable for applications where space is limited. The vertical movement of the cylinder allows for efficient use of vertical space, optimizing storage capacity and workspace utilization.

6. Durability and Longevity:

Lift cylinders are built to withstand rigorous and demanding material handling operations. They are constructed with sturdy materials and designed to withstand heavy loads, repetitive motions, and harsh working conditions. Proper maintenance and care can ensure their longevity, providing reliable performance over an extended period.

7. Safety:

Lift cylinders prioritize safety during material handling operations. They incorporate safety features such as pressure relief valves, load holding devices, and fail-safe mechanisms to prevent accidents or uncontrolled movements. These safety features help protect operators, bystanders, and the materials being lifted.

8. Reduced Manual Labor:

Using lift cylinders in material handling reduces the reliance on manual labor for lifting heavy loads. This improves productivity, reduces the risk of injuries associated with manual lifting, and allows operators to focus on other essential tasks, enhancing overall operational efficiency.

In summary, the advantages of using lift cylinders in material handling include high lifting capacity, precise control, smooth and stable operation, flexibility in application, space efficiency, durability, safety features, and reduced reliance on manual labor. These advantages contribute to improved efficiency, productivity, and safety in material handling operations.

Can lift cylinders be used in manufacturing and production machinery?

Yes, lift cylinders are commonly used in manufacturing and production machinery. Lift cylinders, also known as hydraulic cylinders, are devices that generate linear force and motion through the use of pressurized hydraulic fluid. They are widely employed in various industrial applications for lifting, pushing, pulling, and holding heavy loads.

In manufacturing and production machinery, lift cylinders play a crucial role in providing controlled movement and force for a wide range of tasks. Here are some examples of how lift cylinders are used:

- Material Handling: Lift cylinders are utilized in machinery such as forklifts, cranes, and material handling equipment to lift and transport heavy objects. They allow for precise positioning and movement of loads, improving efficiency and safety in material handling operations.

- Assembly and Automation: Lift cylinders are integrated into assembly lines and automated machinery to perform tasks like part insertion, pressing, and clamping. They provide the necessary force and motion required for assembling components or joining parts together.

- Presses and Punching Machines: Lift cylinders are employed in presses and punching machines to exert force for bending, forming, and shaping materials. These cylinders ensure accurate and consistent results in metalworking processes.

- Industrial Robots: Lift cylinders are used in robotic systems to enable lifting and manipulation of objects. They facilitate the controlled movement of robot arms and end-effectors, allowing robots to perform tasks such as pick-and-place operations, welding, and painting.

Lift cylinders offer several advantages in manufacturing and production machinery. They provide high force capabilities, precise control over movement, compact design, and the ability to operate in various orientations. Furthermore, their hydraulic nature allows for smooth and gradual acceleration and deceleration, reducing the risk of damage to the machinery or the materials being handled.

In conclusion, lift cylinders are extensively utilized in manufacturing and production machinery across different industries. Their versatility, reliability, and ability to generate controlled linear force make them essential components in a wide range of industrial applications.

How does a lift cylinder handle variations in lift height?

A lift cylinder is designed to handle variations in lift height by utilizing its extendable and retractable piston rod. Here’s an explanation of how a lift cylinder handles variations in lift height:

When a lift cylinder is activated, hydraulic fluid is directed into the cylinder chamber, creating pressure that extends the piston rod. As the piston rod extends, it pushes against the load, lifting it to the desired height.

When there are variations in lift height, the lift cylinder adjusts accordingly by controlling the extension and retraction of the piston rod. Here’s how it works:

1. Extending the Piston Rod:

When the lift height needs to increase, the lift cylinder extends the piston rod further. This extension is achieved by increasing the flow of hydraulic fluid into the cylinder chamber. The increased fluid pressure pushes the piston and rod assembly, extending the rod and lifting the load to the required height.

2. Retracting the Piston Rod:

Conversely, when the lift height needs to decrease, the lift cylinder retracts the piston rod. This retraction is achieved by reducing the flow of hydraulic fluid into the cylinder chamber. The decreased fluid pressure allows the piston and rod assembly to retract, lowering the load to the desired height.

3. Precise Control and Positioning:

Lift cylinders are equipped with valves and control mechanisms that allow for precise control and positioning of the piston rod. By regulating the flow of hydraulic fluid and adjusting the pressure, the lift cylinder can achieve accurate and controlled movements, enabling it to handle variations in lift height with precision.

4. Adjustable Stroke Length:

Some lift cylinders have an adjustable stroke length, which refers to the distance the piston rod can travel within the cylinder barrel. By customizing the stroke length, the lift cylinder can accommodate different variations in lift height. The stroke length can be modified by adjusting the cylinder’s dimensions or incorporating additional components.

5. Integration with Control Systems:

Advanced lift cylinder systems can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs), to automate and optimize lift height adjustments. These control systems can monitor and adjust the lift cylinder’s movements based on predetermined parameters or feedback from sensors, ensuring precise and consistent lift height control.

In summary, a lift cylinder handles variations in lift height by extending or retracting the piston rod, controlling the flow and pressure of hydraulic fluid, achieving precise control and positioning, utilizing adjustable stroke length, and integrating with control systems. These capabilities enable the lift cylinder to adapt to different lift height requirements and provide accurate and controlled lifting operations.

editor by Dream 2024-05-07

China Hot selling Wholesale Boom Lift Single Action or Double Acting Excavation Oil Cylinder Hydraulic with Ce vacuum pump booster

Product Description

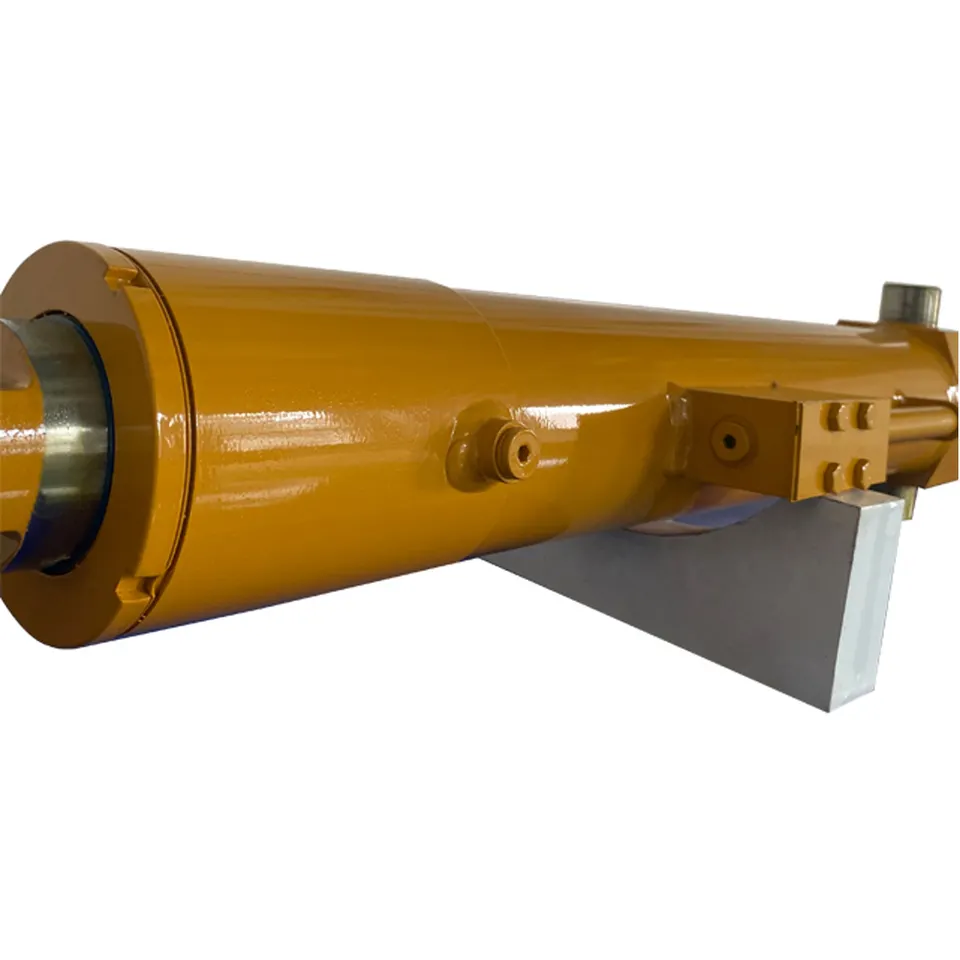

Wholesale Boom Lift Single Action or Double Acting Excavation Oil Cylinder Hydraulic with CE

Product Description

Wholesale Boom Lift Single Action or Double Acting Excavation Oil Cylinder Hydraulic with CE: Assemble with imported seals kits of NOK, SKF, Hallite and other brands to bring the better seal slick and the stronger persistence.

Process with the advanced technology by CNC machine tools, automatic plating and painting equipments to ensure all the parts to have the lower surface roughness and the higher performance level.

Own advanced special buffer device with independent intellectual property rights which can effectively absorb the shock to protect the cylinder work smoothly and reliable in performance.

Specifications

| Item | Specifications |

| Product Name: | Wholesale Boom Lift Single Action or Double Acting Excavation Oil Cylinder Hydraulic with CE |

| Certificate: | CE, ISO9001 |

| Production Capacity: | 200,000 pcs per year |

| Sample Time: | 7-10 days |

| Brand | NOLANSE or customer’s logo |

| Service | OEM & ODM |

| Piston Rod | Chrome or nickel plated,ground & polished piston rod |

| Seal Type | Parker,NOK, BUSAK SHAMBAN or as customer’s requirement |

| Tube | High tensile cold drawn tube, precision honed for extended seal life |

| Delivery Time | Based on order quantity. normally 15-30 days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer & Exporter |

Application

Hydraulic Cylinder Product ApplicationNolanse’s quality custom products are produced for OEM applications in a wide variety of CHINAMFG industries, including manufacturing engineering machinery, loaders hydraulic cylinders, vehicle cylinders, construction, forestry, waste management, mining, material handling, industrial applications, agriculture, manufacturing, transportation, marine applications and oil field equipment. Our success has been built on the engineering expertise and manufacturing capabilities we offer to meet the very specific demands of our industry clients.

Why Choose Us

1. Product Research & Development

CHINAMFG builds quality products that are developed with use in mind. We specialize in working with every customer to share ideas and gather critical information regarding hydraulic cylinder fit and performance requirements for your specific application. This is accomplished by establishing a very close technical rapport with each customer and their engineering, purchasing and R&D departments – the experts in your organization who know best what functionality, quality, size and cylinders characteristics are critical to your equipment. If our standard lines don’t suit your application, CHINAMFG has extensive experience in custom hydraulic cylinder designs. We strive to develop dynamic, innovative and dependable hydraulic and machining solutions that exceed your expectations.

2. Hydraulic Cylinder Production

We have the advanced CNC machine tools, a horizontal machining center, a welding robot, parts cleaning agent, automatic assembly lines, automatic painting equipment etc. to hydraulic cylinder ensure a 360-degree quality control of the production process.

3. Hydraulic Cylinder Product Testing

We check all of the products, using fully equipped facilities and advanced instruments, regarding the performance, structure, size tolerance, roughness, hardness, pressure and sealing to ensure the hydraulic cylinder quality meets the requirements of our different customers.

4.Hydraulic Cylinder Product Certifications

Nolanse is ISO 9001 registered for the design and manufacture of hydraulic cylinders and precision machining.

5. Professional Hydraulic Cylinder Team

NOLANSE professional hydraulic cylinder team deeply understands the requirements and the technological advancement hydraulic ram. NOLANSE has been specialized in custom hydraulic cylinder development, manufacturing, sales, sample verification, order processing and product delivery, etc. NOLANSE is always working hard with passion to put our efforts to hydraulic cylinder technology and application.

Company Information

As a leader in hydraulic cylinder Design, Manufacturing and Custom Machining for over 36 years, NOLANSE has its own over 220 employees and over 55,000 square CHINAMFG manufacturing factories. We have professional departments including hydraulic cylinder design, sales, production, quality control department, etc.

NOLANSE hydraulic cylinder products mainly include manufacturing engineering machinery,loaders hydraulic cylinders,vehicle cylinders,hydraulic systems and air controlling systems.It can also manufacture large-scale,non-standard and different stypes of cylinders, etc. All our hydraulic cylinder are manufactured from high quality raw materials with strict professional process and quality assurance. We had been worked hard and invested more to become the leader in hydraulic cylinder industry. Our partners are those famous hydraulic cylinder brands from America, Canada, Australia, Germany, England and other European Countries. Product quality, shorter delivery time and customer satisfaction are our long term commitment to our CHINAMFG customers. Hope to be your partner.

Nolanse’s name has become synonymous with quality, on time delivery and exceptional service.

Join the growing number of partner relationship companies that trust and rely on the CHINAMFG name.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Samples: |

US$ 899/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lift cylinders be used in both mobile and stationary applications?

Yes, lift cylinders can be used in both mobile and stationary applications. Here’s an explanation of how lift cylinders are suitable for both types of applications:

Mobile Applications:

In mobile applications, lift cylinders are commonly used in various types of equipment that require lifting capabilities. Some examples include:

- Forklifts: Lift cylinders are essential components in forklifts, enabling them to lift and lower loads efficiently. They provide the lifting force needed to raise the forks and transport materials.

- Cranes: Lift cylinders are utilized in cranes to lift and position heavy objects. They play a vital role in the vertical movement of the crane’s boom and ensure controlled lifting operations.

- Scissor Lifts: Lift cylinders are integral to scissor lifts, enabling the platform to be raised or lowered. They provide the necessary force to extend and retract the scissor arms, allowing for elevation changes.

- Aerial Work Platforms: Lift cylinders are employed in aerial work platforms, such as cherry pickers or boom lifts. They facilitate the vertical movement of the platform, enabling operators to access elevated areas safely.

Stationary Applications:

In stationary applications, lift cylinders are commonly used in various industrial and commercial settings. Some examples include:

- Material Handling: Lift cylinders are utilized in stationary material handling equipment, such as conveyor systems or lift tables. They enable the vertical movement of materials, facilitating efficient loading, unloading, or positioning.

- Automotive Lifts: Lift cylinders are employed in automotive lifts used in garages or car service centers. They provide the lifting force needed to raise vehicles for maintenance, repairs, or inspections.

- Industrial Machinery: Lift cylinders are integrated into various industrial machinery, such as hydraulic presses or assembly line equipment. They assist in lifting heavy components or adjusting the position of workpieces during manufacturing processes.

- Warehouse Systems: Lift cylinders are used in stationary warehouse systems, including vertical storage systems or automated retrieval systems. They contribute to efficient vertical movement of goods, optimizing storage and retrieval processes.

Whether in mobile or stationary applications, lift cylinders offer the necessary force and control to perform lifting tasks. Their versatility and adaptability make them suitable for a wide range of industries and applications.

“`

Can lift cylinders be used in automotive lifting equipment?

Yes, lift cylinders can be used in automotive lifting equipment. Here’s an explanation of how lift cylinders are utilized in automotive lifting systems:

Lift cylinders play a crucial role in various types of automotive lifting equipment, providing the necessary force to raise vehicles for maintenance, repairs, or inspections. Here are some common examples:

- Automotive Lifts: Lift cylinders are integral components of automotive lifts, such as two-post lifts, four-post lifts, or scissor lifts. These lifts are used in garages, auto repair shops, or car service centers to elevate vehicles to a convenient working height. Lift cylinders are responsible for the vertical lifting motion of the lift platform or arms, allowing easy access to the undercarriage or other areas of the vehicle.

- Parking Lifts: Lift cylinders are also employed in parking lifts, also known as car stackers or vehicle storage lifts. These lifts are used to maximize parking space in residential or commercial settings. Lift cylinders enable the vertical movement of the lift platforms, allowing vehicles to be stacked vertically for efficient use of space.

- Wheel Alignment Lifts: Lift cylinders are utilized in wheel alignment lifts, which are specifically designed for performing wheel alignment or suspension work. Lift cylinders raise the vehicle to a suitable height, enabling technicians to access the wheels and suspension components for adjustments or repairs.

Lift cylinders in automotive lifting equipment are typically hydraulic cylinders. They utilize hydraulic fluid and pressure to generate the necessary force for lifting heavy vehicles. The hydraulic system includes a pump, control valves, and hydraulic lines that deliver the pressurized fluid to the lift cylinders.

When activated, the hydraulic pump pressurizes the fluid, which is then directed to the lift cylinders through control valves. The pressurized fluid causes the pistons within the lift cylinders to extend, thereby lifting the platform or arms of the lifting equipment. By adjusting the flow and pressure of the hydraulic fluid, operators can control the lifting process and achieve the desired working height.

In addition to lifting capabilities, automotive lift cylinders are designed with safety features to ensure secure and reliable operation. These features may include safety locks, mechanical or hydraulic safety systems, and overload protection mechanisms. These safety measures help prevent accidents or equipment failure during the lifting process.

In summary, lift cylinders are commonly used in automotive lifting equipment, providing the lifting force necessary for vehicle maintenance, repairs, and storage. Their hydraulic operation and incorporation of safety features make them essential components in automotive service facilities, contributing to efficient and reliable vehicle lifting operations.

Can Lift Cylinders Be Used in Lifting and Lowering Platforms for Accessibility?

Yes, lift cylinders can be used in lifting and lowering platforms to provide accessibility for individuals with mobility challenges. These cylinders play a crucial role in the operation of accessibility platforms, such as wheelchair lifts, vertical platform lifts, or scissor lifts. Here’s a detailed explanation of how lift cylinders can be used in lifting and lowering platforms for accessibility:

- Lifting Mechanism:

- Smooth and Controlled Movement:

- Weight Capacity:

- Space Optimization:

- Reliability and Durability:

- Integration with Safety Features:

Lift cylinders serve as the primary lifting mechanism in accessibility platforms. These platforms are designed to raise or lower individuals, including wheelchair users, to different heights, allowing them to access elevated areas or overcome vertical barriers. Lift cylinders are typically integrated into the platform structure and connected to a hydraulic or pneumatic system. When activated, the cylinders extend or retract, lifting or lowering the platform in a controlled manner.

Lift cylinders ensure smooth and controlled movement of the accessibility platform during the lifting and lowering process. The cylinders are designed to provide precise and gradual motion, allowing for safe and comfortable vertical transportation. They can be equipped with features such as flow control valves or adjustable dampening to regulate the speed and prevent abrupt movements. Lift cylinders enable individuals to transition between different levels smoothly and securely.

Accessibility platforms need to support the weight of individuals using them, including wheelchair users and their mobility devices. Lift cylinders are manufactured with varying weight capacities to accommodate different load requirements. The cylinders are designed to withstand the vertical forces exerted on the platform and ensure stability and safety during operation. Lift cylinder specifications, such as bore size, rod diameter, and material strength, are carefully selected to match the intended weight capacity of the accessibility platform.

Lift cylinders contribute to space optimization in accessibility platforms. These cylinders are compact and can be integrated within the platform structure, minimizing the need for additional space or external lifting mechanisms. The compact design of lift cylinders allows for efficient utilization of the available platform area, ensuring that the platform can be installed in various settings, including tight spaces or existing structures where space is limited.

Lift cylinders are engineered for reliability and durability to meet the demanding requirements of accessibility platforms. They are designed to withstand frequent usage, heavy loads, and harsh operating conditions. Lift cylinders undergo rigorous testing and quality control measures to ensure their performance and longevity. Manufacturers often provide warranties and maintenance guidelines to support the long-term reliability and safety of lift cylinders used in lifting and lowering platforms.

Accessibility platforms incorporate various safety features to protect users during vertical transportation. Lift cylinders can be integrated with these safety features to enhance the overall system. For example, pressure relief valves can be installed in the hydraulic system to prevent excessive force in case of a malfunction or overload. Additionally, safety sensors, emergency stop buttons, and interlocks can be connected to the lift cylinder system to provide additional layers of safety and control.

Lift cylinders are essential components in lifting and lowering platforms for accessibility. Their role in providing the lifting mechanism, ensuring smooth and controlled movement, accommodating weight capacity, optimizing space, and contributing to reliability and safety makes them a valuable choice for creating inclusive environments and improving accessibility for individuals with mobility challenges.

How does a lift cylinder contribute to precise load positioning?

A lift cylinder plays a crucial role in achieving precise load positioning in various applications. Here’s an explanation of how a lift cylinder contributes to precise load positioning:

1. Controlled Vertical Motion:

A lift cylinder provides controlled vertical motion, allowing for accurate and precise movement of the load. By adjusting the hydraulic fluid flow and pressure, the cylinder extends or retracts with the desired speed and smoothness. This controlled motion enables precise positioning of the load at the desired height or location.

2. Adjustable Stroke Length:

Lift cylinders often have an adjustable stroke length, which refers to the distance the piston can travel within the cylinder barrel. By customizing the stroke length according to the specific load positioning requirements, the cylinder can achieve the desired precision. This adjustability allows for fine-tuning the cylinder’s movement to accurately position the load with precision.

3. Load Holding Capability:

Lift cylinders are designed to have load holding capability, meaning they can maintain the position of the load without drifting or unwanted movement. This is achieved through the use of seals, locking mechanisms, or pressure control valves that prevent the cylinder from extending or retracting unintentionally. The load holding capability ensures that once the load is positioned precisely, it remains stable and secure.

4. Sensing and Feedback Systems:

Advanced lift cylinder systems may incorporate sensing and feedback mechanisms to enhance load positioning precision. These systems use sensors to measure the position, force, or pressure within the cylinder and provide feedback to the control system. This real-time feedback allows for continuous adjustments and fine-tuning of the cylinder’s movements, ensuring precise load positioning.

5. Integration with Control Systems:

Lift cylinders can be integrated with control systems that enable precise load positioning. Through electronic controls or programmable logic controllers (PLCs), the cylinder’s movement can be precisely controlled and coordinated with other equipment or processes. This integration allows for synchronized movements and accurate load positioning in complex automation systems.

In summary, a lift cylinder contributes to precise load positioning through controlled vertical motion, adjustable stroke length, load holding capability, sensing and feedback systems, and integration with control systems. These features and capabilities enable lift cylinders to achieve the precise positioning required in various applications, ranging from material handling to industrial automation.

editor by Dream 2024-04-23

China high quality China Factory Custom Made Long Stroke Hydraulic Press Cylinder Lift Parts Oil vacuum pump distributors

Product Description

Welcome To CHINAMFG HYDRAULICS!

Product Description

Product Parameters

Technical Data

| Cylinder Type | Mill type, Head Bolted, Base Welded |

| Bore Diameter | Up to 2500mm |

| Rod Diameter | Up to 2000mm |

| Stroke Length | Up to 20,000mm |

| Piston Rod Material | AISI 1045, AISI 4140, AISI 4340, 20MnV6, Stainless steel 2Cr13 or 1Cr17Ni2 |

| Rod Surface Treatment | Hard chrome plated, Chrome/Nickel plated, Ceramic coated |

| Tube Material | Carbon steel AISI1045 or ST52.3, Alloy steel AISI4140 or 27SiMn |

| Tube Surface Painting | Colors according to RAL and thickness according to customer needs |

| Mounting Type | Clevis, Cross tube, Flange, Trunnion, Tang, Thread |

| Design Pressure | Up to 40Mpa |

| Seal Kits Type | PARKER, MERKEL, HALLITE, NOK, TRELLEBORG |

| Quality Assurance | 1 year |

| Certificate | SGS, BV, ABS ,GL, DNV etc. |

| Application | Mobile Equipment,Cement Mill, steel mill, Hydraulic press, etc. |

Quality Assurance

| Quality Process | Our quality management system is certified to ISO 9001 |

| Quality control standards include material records, process control plans, | |

| Manufacturing approvals and inspection data | |

| Testing Standards | All products undergo 100% pressure testing 1.5 times the maximum allowable working pressure or to customer specifications |

| Static and dynamic pressure testing. | |

| Ultraviolet leak detection technology. | |

| Non-destructive testing. | |

| Fluid Cleanliness | Real-time monitoring and test phase documentation |

| Independent sampling and oil diagnostic control |

Finished Product Display

Application Area

Company Profile

FLUTEC HYDRAULICS is an expert at designing and manufacturing a broad range of custom engineered hydraulic cylinders and cylinder systems as well as custom engineered press bolster plates. We are proud to offer superior quality products and services for various applications including industrial, construction, mobile, agricultural, mining, steel mill, hydraulic press, etc. Our highly skilled team and modern technical facilities allow us to manufacture large bore hydraulic cylinders and long stroke hydraulic cylinders with 100% confidence and assurance.

We understand our customers need dependable quality and excellent services with affordable cost to stay ahead in today’s highly competitive market. CHINAMFG HYDRAULICS can meet those requirements with our robust, efficient and long life products together with prompt services.

To be mentioned, our sales team is strictly trained both in technology and language. They are full of experiences in fluid power and machinery. We are glad to personally visit our customers to work better.

FAQ

Q1: What does your company do?

A: we are a supplier of high-quality hydraulic products including Hydraulic Cylinder,Honed Tube,Chromed Rod,Machined Platen,Cylinder Parts, and other components.

Q2:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q3: Are you able to make Non-standard or customized products?

A: Yes, we can. Custom-made Hydraulic Cylinder is our key business.

Q4: How long is your delivery time?

A: The delivery time for customized products is 30 working days.But it also depends on the product requirements and quantity.

Q5: Do you provide samples?

A: No, we don’t provide samples.

Q6: What are your payment terms?

A: T/T/ or L/C or D/P. If you have any questions, please feel free to contact us.

Q7: What are your After-sales services?

A: Before shipment, Each individual product will be strictly inspected on our factory QC Process System. In addition, We have a Customer Service team to respond to customers’ questions within 12 hours. Being helpful in solving customers’ problems is always our goal.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001, Dnv, SGS, BV, ABS, Gl |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lift cylinders be used in aerial work platforms and scissor lifts?

Yes, lift cylinders are commonly used in aerial work platforms and scissor lifts. Here’s an explanation of their utilization in these types of equipment:

Aerial work platforms, also known as aerial lifts or elevated work platforms, are used to provide elevated access for various tasks, such as maintenance, construction, or inspection work. Scissor lifts are a specific type of aerial work platform that utilize a scissor mechanism to vertically extend the platform. Lift cylinders play a crucial role in the lifting operation of both aerial work platforms and scissor lifts.

In scissor lifts, multiple lift cylinders are typically positioned vertically and connected to the scissor mechanism. These lift cylinders work in synchronization to extend or retract the scissor arms, thereby raising or lowering the platform. The lift cylinders exert force to expand the scissor arms, creating a lifting motion that allows the platform to reach elevated positions. By controlling the flow of hydraulic fluid to the lift cylinders, operators can easily adjust the platform height and achieve the desired working elevation.

Lift cylinders used in aerial work platforms and scissor lifts are usually hydraulic cylinders. Hydraulic systems offer the advantages of smooth operation, precise control, and high lifting capacities. The hydraulic system includes a pump, control valves, hydraulic lines, and the lift cylinders. When the hydraulic system is activated, the pump pressurizes the hydraulic fluid, which is then directed to the lift cylinders through the control valves. The pressurized fluid causes the lift cylinders to extend, resulting in the upward movement of the platform.

One of the key benefits of using lift cylinders in aerial work platforms and scissor lifts is their ability to provide stable and controlled lifting. The synchronized movement of the lift cylinders ensures that the platform remains level and secure during the lifting process. This stability is essential for safe working conditions at elevated heights.

In addition to lifting capabilities, lift cylinders in aerial work platforms and scissor lifts may incorporate features such as safety locks, overload protection, or emergency descent mechanisms. These safety measures enhance the overall performance and reliability of the equipment, ensuring the well-being of operators working at height.

Overall, lift cylinders are integral components in aerial work platforms and scissor lifts, enabling the vertical lifting motion and providing stability during elevated work. Their hydraulic operation, synchronized movement, and safety features make them essential for efficient and secure access at height.

How Does a Lift Cylinder Handle Variations in Cylinder Mounting and Configuration?

A lift cylinder is designed to handle variations in cylinder mounting and configuration, allowing for flexibility in different application scenarios. The construction and features of lift cylinders enable them to adapt to different mounting orientations and accommodate variations in configuration. Here’s a detailed explanation of how a lift cylinder handles variations in cylinder mounting and configuration:

- Mounting Flexibility:

- Adjustable Stroke Length:

- Modular Design:

- Flexible Mounting Accessories:

- Customization Options:

- Compliance with Industry Standards:

Lift cylinders are engineered to provide mounting flexibility, allowing them to be installed in various orientations and positions. They can be mounted vertically, horizontally, or at inclined angles, depending on the specific requirements of the application. Lift cylinders often feature versatile end caps, mounting brackets, or clevis mounts that can be adjusted or rotated to accommodate different mounting orientations. This flexibility enables lift cylinders to fit into different equipment designs and configurations.

Stroke length refers to the distance the piston rod of a lift cylinder extends or retracts during operation. Lift cylinders are designed with adjustable stroke length capabilities, which allow for customization according to specific mounting and configuration requirements. By adjusting the stroke length, the lift cylinder can accommodate variations in the available space or the desired range of motion. This adjustability ensures that the cylinder can be properly installed and operate effectively within the given constraints.

Many lift cylinders feature a modular design, allowing for easy customization and adaptation to different mounting and configuration needs. Modular lift cylinders consist of separate components that can be assembled or disassembled, providing flexibility in terms of length, rod diameter, mounting options, and other specifications. These modular components can be combined or replaced to match specific equipment requirements. The modular design enables lift cylinders to handle variations in mounting and configuration, making them versatile and adaptable for different applications.

Lift cylinders are often accompanied by a range of mounting accessories and attachments that enhance their adaptability. These accessories include clevis brackets, trunnion mounts, spherical bearings, pivot pins, and other connection components. These mounting accessories offer multiple options for securely attaching the lift cylinder to the equipment or machinery. They provide flexibility in terms of positioning, alignment, and angle adjustment, enabling the lift cylinder to accommodate variations in cylinder mounting and configuration.

Lift cylinder manufacturers often offer customization options to meet specific mounting and configuration requirements. This customization may involve modifications to the cylinder’s dimensions, mounting interfaces, rod ends, or other design aspects. By working closely with the manufacturer, equipment designers and engineers can ensure that the lift cylinder is tailored to fit the unique mounting and configuration needs of their application. Customization options allow for precise integration of the lift cylinder, ensuring optimal performance and compatibility.

Lift cylinders adhere to industry standards and guidelines, ensuring compatibility with commonly used mounting and configuration practices. These standards establish criteria for cylinder dimensions, mounting hole patterns, rod end dimensions, and other specifications. By complying with these standards, lift cylinders ensure that they can be easily integrated into various equipment designs and configurations without requiring significant modifications or adaptations.

The combination of mounting flexibility, adjustable stroke length, modular design, flexible mounting accessories, customization options, and compliance with industry standards enables lift cylinders to handle variations in cylinder mounting and configuration. This adaptability allows lift cylinders to be effectively utilized in a wide range of applications, accommodating different equipment designs and requirements.

Can lift cylinders be used for both lifting and lowering applications?

Yes, lift cylinders are designed to be versatile and can be used for both lifting and lowering applications. Here’s an explanation of how lift cylinders are utilized for both lifting and lowering:

Lift cylinders are a type of hydraulic cylinder that converts fluid pressure into linear motion. They consist of a cylinder barrel, a piston, a rod, and seals. When hydraulic fluid is pressurized and directed into the cylinder, it exerts force on the piston, causing it to move in a linear direction.

Lifting Applications:

In lifting applications, the lift cylinder extends to raise or lift a load. As hydraulic fluid is pumped into the cylinder, the pressure increases, pushing the piston and rod outward. This extension of the cylinder generates the necessary force to lift the load. The lifting capacity of the cylinder depends on its design, including the diameter of the piston and the pressure rating of the system.

Lowering Applications:

For lowering applications, the lift cylinder retracts to lower the load. By controlling the flow of hydraulic fluid out of the cylinder, the pressure is reduced, allowing the weight of the load to push the piston and rod back into the cylinder. This controlled retraction enables smooth and controlled lowering of the load.

Lift cylinders are commonly used in various industries and applications where controlled vertical motion is required. Examples include lifting platforms, scissor lifts, dump trucks, hydraulic elevators, and material handling equipment. The ability to perform both lifting and lowering actions makes lift cylinders highly versatile and adaptable to different operational needs.

In summary, lift cylinders can be utilized for both lifting and lowering applications. By controlling the flow of hydraulic fluid, these cylinders can extend to lift a load and retract to lower it, offering flexibility and efficiency in a wide range of industries and equipment.

editor by Dream 2024-04-19

China Custom Lift Freight Elevator Hydraulic Cylinder Large Tonnage Hydraulic Cylinder vacuum pump oil near me

Product Description

Lift freight elevator hydraulic cylinder Large tonnage hydraulic cylinder

Product Description:

Lift freight elevator hydraulic cylinder Large tonnage hydraulic cylinder has high requirements for security performance, as it works frequently with large shock and vibration, so the requirements of reliability is high. Limit working condition bear large lateral load, so it has higher requirements for hardness and wear resistance.

Product Features:

(1) Single cylinder latch interlock technology ensure reliability and security;

(2) New type counterweighing hooking technology ensure the stability performance;

(3) Large span guidance technology and oil & gas mixture suspension technology ensure the system stable and reliable.

Product Display:

Specifications:

| Item | Specifications |

| Product Name | Lift freight elevator hydraulic cylinder Large tonnage hydraulic cylinder |

| Certificate: | CE, ISO9001 |

| Production Capacity: | 5000pcs/Month |

| Sample Time | 7-10 days |

| Brand | GLIT or customer’s logo |

| Service | OEM & ODM |

| Piston Rod | Chrome or nickel plated,ground & polished piston rod |

| Seal Type | Parker,NOK, BUSAK SHAMBAN or as customer’s requirement |

| Tube | High tensile cold drawn tube, precision honed for extended seal life |

| Delivery Time | Based on order quantity. normally 15-30 days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer & Exporter |

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Packing & Delivery:

Appliactions:

Application: Mobile Cranes, Trailer, excavator, log splitter, hydraulic press, garbage compactor,

lift platform, dock leveler

About US:

HangZhou GLORIA INDUSTRIAL TECH CO.,LTD. is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, CHINAMFG provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, GLIT can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 20-30 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 40% when order is confirmed and 60% before shipment. L/C is also acceptable for amount over 20,000USD.

9, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | 10-35 MPa |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

How does a lift cylinder handle variations in fluid pressure and flow rate?

A lift cylinder is designed to handle variations in fluid pressure and flow rate in order to ensure smooth and controlled operation. Here’s an explanation of how lift cylinders handle these variations:

1. Fluid Pressure:

Lift cylinders are typically part of a hydraulic system that utilizes pressurized fluid to generate the necessary force for lifting. The lift cylinder is designed to withstand varying fluid pressure levels. When the fluid pressure is increased, the lift cylinder can handle the additional force exerted on its piston. Conversely, when the fluid pressure decreases, the lift cylinder adjusts accordingly and maintains its functionality.

2. Flow Rate:

The flow rate of hydraulic fluid determines the speed at which the lift cylinder extends or retracts. Lift cylinders are designed to accommodate variations in flow rate. By controlling the flow rate of the hydraulic fluid through the use of control valves or flow control devices, operators can adjust the speed of the lift cylinder’s movement. This allows for precise and controlled lifting operations.

3. Control Valves:

Control valves are an integral part of the hydraulic system that regulates the fluid pressure and flow rate. Lift cylinders are often equipped with control valves that enable operators to control the movement of the cylinder by adjusting the pressure and flow of the hydraulic fluid. These valves can be manually operated or automated, providing flexibility in handling variations in fluid pressure and flow rate.

4. Cylinder Design:

Lift cylinders are designed to be robust and durable, capable of withstanding variations in fluid pressure and flow rate. The cylinder’s construction and materials are selected to ensure optimal performance under different operating conditions. Seals and other components within the lift cylinder are designed to maintain their functionality and prevent leakage, even when subjected to changes in fluid pressure and flow rate.

5. Fluid Control Systems:

In more advanced lift cylinder systems, fluid control systems may be employed to handle variations in fluid pressure and flow rate. These systems can include pressure relief valves, flow control valves, or proportional valves. Pressure relief valves protect the lift cylinder and the hydraulic system from excessive pressure, while flow control valves regulate the flow rate of the hydraulic fluid. Proportional valves provide precise control over both pressure and flow, allowing for fine-tuning of the lift cylinder’s movement.

In summary, lift cylinders are designed to handle variations in fluid pressure and flow rate to ensure smooth and controlled lifting operations. With the use of control valves, robust cylinder design, and fluid control systems, lift cylinders can adapt to changes in fluid pressure and flow rate, providing reliable and efficient performance.

Can lift cylinders be used in manufacturing and production machinery?

Yes, lift cylinders are commonly used in manufacturing and production machinery. Lift cylinders, also known as hydraulic cylinders, are devices that generate linear force and motion through the use of pressurized hydraulic fluid. They are widely employed in various industrial applications for lifting, pushing, pulling, and holding heavy loads.

In manufacturing and production machinery, lift cylinders play a crucial role in providing controlled movement and force for a wide range of tasks. Here are some examples of how lift cylinders are used:

- Material Handling: Lift cylinders are utilized in machinery such as forklifts, cranes, and material handling equipment to lift and transport heavy objects. They allow for precise positioning and movement of loads, improving efficiency and safety in material handling operations.

- Assembly and Automation: Lift cylinders are integrated into assembly lines and automated machinery to perform tasks like part insertion, pressing, and clamping. They provide the necessary force and motion required for assembling components or joining parts together.

- Presses and Punching Machines: Lift cylinders are employed in presses and punching machines to exert force for bending, forming, and shaping materials. These cylinders ensure accurate and consistent results in metalworking processes.

- Industrial Robots: Lift cylinders are used in robotic systems to enable lifting and manipulation of objects. They facilitate the controlled movement of robot arms and end-effectors, allowing robots to perform tasks such as pick-and-place operations, welding, and painting.

Lift cylinders offer several advantages in manufacturing and production machinery. They provide high force capabilities, precise control over movement, compact design, and the ability to operate in various orientations. Furthermore, their hydraulic nature allows for smooth and gradual acceleration and deceleration, reducing the risk of damage to the machinery or the materials being handled.

In conclusion, lift cylinders are extensively utilized in manufacturing and production machinery across different industries. Their versatility, reliability, and ability to generate controlled linear force make them essential components in a wide range of industrial applications.

How does a lift cylinder differ from other types of hydraulic cylinders?

A lift cylinder, also known as a hydraulic lift cylinder or hydraulic lifting cylinder, has some distinct characteristics that set it apart from other types of hydraulic cylinders. Here’s an explanation of how a lift cylinder differs from other hydraulic cylinders:

While hydraulic cylinders come in various types and designs, including single-acting, double-acting, telescopic, and differential, a lift cylinder typically refers to a double-acting cylinder. Here are some key differences:

1. Double-Acting Design:

A lift cylinder is generally designed as a double-acting cylinder, meaning it can generate force in both the extension and retraction strokes. This allows for bidirectional movement and greater flexibility in lifting and lowering operations. In contrast, some other types of hydraulic cylinders, such as single-acting cylinders, generate force in only one direction.

2. Linear Motion:

The primary function of a lift cylinder is to provide linear motion for lifting and lowering loads. It is specifically designed to generate vertical movement, making it suitable for applications that require vertical displacement, such as hydraulic lifts, scissor lifts, and elevating platforms.

3. Load Capacity:

Due to their design and intended use, lift cylinders are typically designed to handle heavier loads compared to other types of hydraulic cylinders. They are engineered to provide high lifting capacities and withstand the forces associated with lifting heavy objects.

4. Control Valve Configuration:

Lift cylinders often require specialized control valve configurations to regulate their operation. This is because precise control is crucial in lifting and lowering operations, especially in applications where safety and accuracy are paramount, such as in hydraulic lifts or elevators.

5. Application-Specific:

While other types of hydraulic cylinders have diverse applications across various industries, lift cylinders are commonly used in specific applications that require vertical lifting and lowering. They are frequently employed in hydraulic lifts, scissor lifts, material handling equipment, and other vertical motion systems.

6. Construction and Mounting:

Lift cylinders may have specific construction features and mounting options to accommodate their application requirements. For example, they may include features like safety locks, cushioning mechanisms, or specialized mounting brackets to ensure secure and efficient operation in lifting applications.

In summary, a lift cylinder differs from other types of hydraulic cylinders in terms of its double-acting design, focus on linear motion for lifting and lowering, higher load capacity, specialized control valve configuration, application-specific usage, and construction features tailored for lifting applications. These distinctions make lift cylinders well-suited for vertical motion systems and applications that require reliable and precise lifting operations.

editor by CX 2024-04-12

China high quality Made in China Double Acting Hydraulic Oil Cylinder with Lift Articulated Construction vacuum pump ac

Product Description

Product Description

1.About Price

Due to the product and industry characteristics, linear actuators are always customized and made-to-order.

The exact quotation varies for the model, configuration and quantity you required, so the prices displayed on this page are for reference only.

You can go to the customer service and leave your rough requirements and contacts. Packway will match you with professional engineers and provide one-to-1 technical support.

2.Product Parameters

Made in China Double Acting Hydraulic Oil Cylinder with Lift Articulated Construction

1)Cylinder Barrel

Hydraulic Equipment includes Engineering Hydraulic Cylinder, Hydraulic Cylinder for metallurgical equipment, Hydraulic Cylinder For Industry and Thin Hydraulic Cylinder, etc. The commonly used materials of DGR-MOB Series hydraulic cylinder are seamless steel pipes of 20#, 35#, and 45#, which have been honed or rolled to meet the European roughness requirements of less than 0.4um. Low pressure oil cylinders can use 20# steel pipes, while high pressure oil cylinders can use 45# steel pipes.

2) Piston Rod

There are 2 types of piston rods: CHINAMFG rod and hollow rod. One end of the hollow piston rod should have a vent hole for welding and heat treatment.

The material of the plug rod is 35# and 45# steel, and the material of the hollow piston rod is 35# and 45# seamless steel pipe.

After rough machining, the piston rod is quenched and tempered to a hardness of 229-285HB. If necessary, it is then subjected to high-frequency quenching to achieve a hardness of 45-55HRC.

3) Cylinder Head

Castings for low pressure, HT300 gray iron for medium and low pressure, and 35# and 45# steel for medium and high pressure.

When the cylinder head itself is the guide sleeve of the piston rod, it is best to choose cast iron for the cylinder head. At the same time, brass, bronze. or other wear-resistant materials should be melted CHINAMFG the quide surface. If a structure with a guide sleeve pressed into the cylinder head is used, the guide sleeve should be wear-resistant cast iron, bronze, or brass.

4) Piston

Commonly used materials are wear-resistant cast iron, gray cast iron (HT300, HT350), steel, and aluminum alloy. The coaxiality tolerance value of the piston and piston rod in the structural diagram should be 0.03mm.

| Dia of Rod Cylinder: | 30-300mm |

| Dia of Cylinder Tube: | 32-500mm |

| Stroke: | 10-5000mm |

| Working Pressure: | 5-32MPa |

| Cylinder Material: | Ht300 |

| Operating Temperature: | -40ºC~+50ºC |

| Out-of-Warranty Service: | Video Technical Support, Online Support |

3.Product Show

Features

1.High Strength

2.High Performance

3.Light Weight

4.Excellent Design

5.Manufacturing Capabilities

6.Custom Cylinder Features

Application

Hydraulic cylinders are widely used in engineering machinery, molds, automobiles, mines, metallurgy, aviation, ships, agriculture, environmental protection and other industries.

Certifications

Our factory has passed the certificate: ISO9001/ISO14001/CE/ROHS

Packaging & Shipping

FAQ

Q1. What are your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown wooden cartons. If you have a legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What are your terms of payment?

A: T/T 50% as deposit, and 50% before shipping. We’ll show you the photos of the products and packages before

you pay the balance.

Q3. What are your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 10-25 days to produce the products, and 5days by air, 25 days of the ship by sea. The specific delivery time depends on the items and the quantity of your order.

Q5: How is the warranty system?

A: 1~5 years. (upon the deal)

Q6. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q7. What is your sample policy?

A: We can supply the sample, but the customers have to pay the sample cost and the courier cost.

Q8. Do you test all your goods before delivery?

A: Yes, we have a 100% test before delivery.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Low Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

Can lift cylinders be used in hydraulic vehicle lifts?

Yes, lift cylinders are commonly used in hydraulic vehicle lifts. Here’s an explanation of their utilization in hydraulic vehicle lifts:

Hydraulic vehicle lifts are devices used to raise vehicles for maintenance, repairs, or storage purposes. Lift cylinders play a crucial role in the lifting operation of these hydraulic lifts.

In hydraulic vehicle lifts, lift cylinders are typically positioned vertically and connected to the lifting platform or arms. The lift cylinders work by converting hydraulic pressure into mechanical force, allowing the platform or arms to lift the vehicle. When the hydraulic system is activated, the hydraulic fluid is pressurized, and it flows into the lift cylinders. The force exerted by the pressurized fluid causes the lift cylinders to extend, resulting in the upward movement of the lifting platform or arms.

Lift cylinders used in hydraulic vehicle lifts are usually hydraulic cylinders. Hydraulic systems offer the advantages of smooth operation, precise control, and high lifting capacities. The hydraulic system includes a pump, control valves, hydraulic lines, and the lift cylinders. By controlling the flow of hydraulic fluid to the lift cylinders, operators can easily adjust the lifting height and position of the vehicle.

One of the key benefits of using lift cylinders in hydraulic vehicle lifts is their ability to provide stable and controlled lifting. The lift cylinders are designed to handle the weight of vehicles and ensure safe and secure lifting. They offer reliable support and stability throughout the lifting process, allowing technicians to work on vehicles with confidence.

In addition to lifting capabilities, lift cylinders in hydraulic vehicle lifts may incorporate safety features such as locking mechanisms or overload protection. These safety measures enhance the overall performance and reliability of the lifts, ensuring the safety of both the vehicle and the operators.

Overall, lift cylinders are integral components in hydraulic vehicle lifts, enabling the vertical lifting motion and providing stability during vehicle maintenance and repair operations. Their hydraulic operation, strength, and safety features make them essential for efficient and safe vehicle lifting.