Product Description

China Manufacturer Mining Dump Truck Spare Parts Front Rear Ride Oil Suspension Nitrogen Hydraulic Cylinder Made in China

Product Description:

Widely used in equipment for Coal&mine,Engineering.

Special structural design, high-strength material use, and special heat treatment and welding processes ensure that the oil cylinder has extremely high fatigue durability under high pressure and heavy load.

The front and rear suspension cylinders can be analyzed and calculated based on the parameters provided by customers, and the stiffness and damping curves required by customers can be designed.

The surface of the piston rod adopts special surface treatment to ensure excellent wear and corrosion resistance of the piston rod.

Select heavy-duty sealing rings to meet the harsh working conditions of the mining area, ensuring excellent dustproof and sealing performance of the oil cylinder.

Select a wide series and high bearing capacity integrated guide ring, with strong lateral force resistance.

The interior of the lifting cylinder can be designed with a buffer structure to avoid excessive impact during lifting and lowering processes.

The steering cylinder can be equipped with a built-in displacement sensor to monitor the cylinder stroke in real-time.

The piston accumulator adopts a dual piston design, with high and low pressure chambers to meet various road conditions.

The reliable sealing structure design of the piston accumulator ensures the separation of oil and gas.

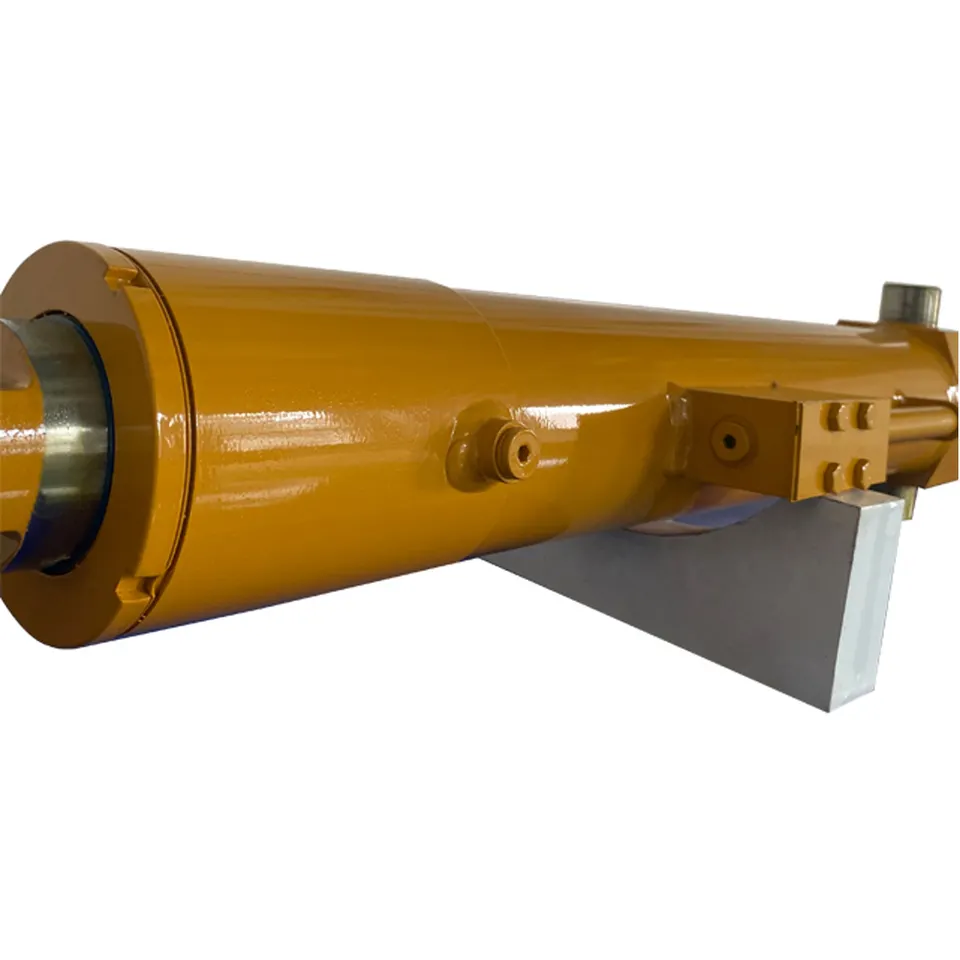

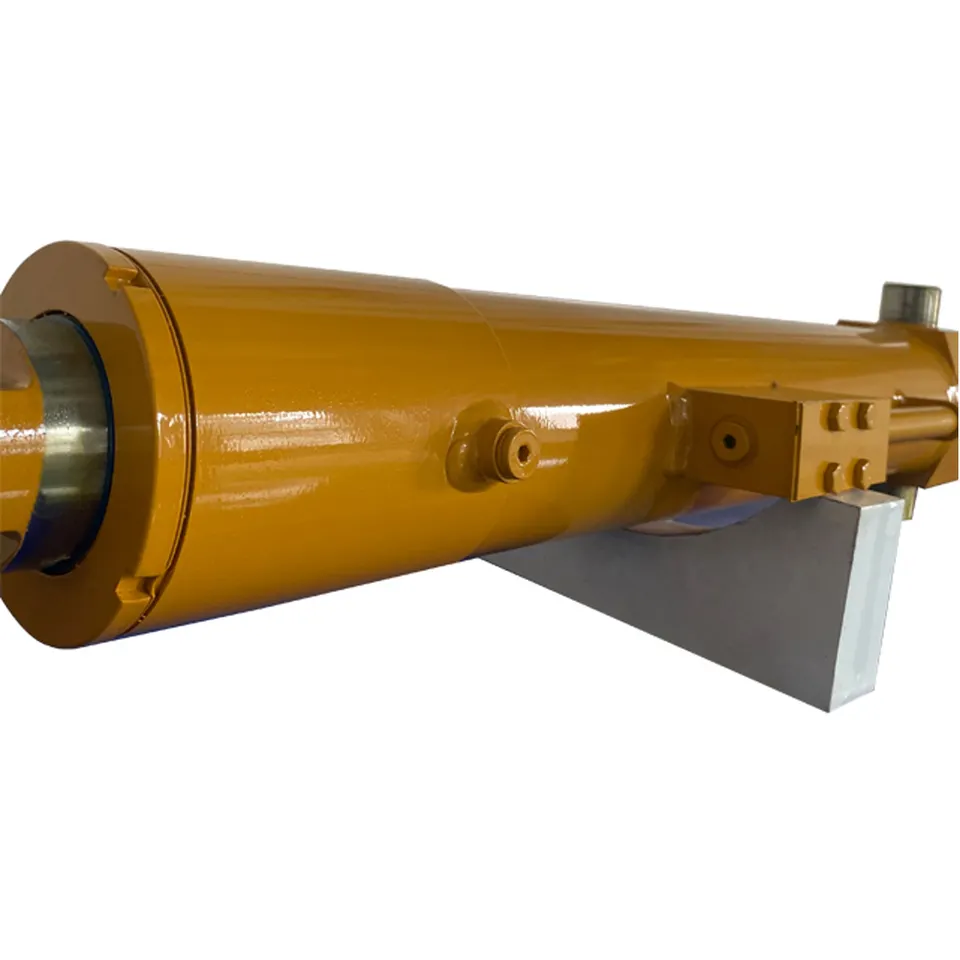

Product Display:

Front suspension cylinder for mining dump truck

Rear suspension cylinder for mining dump truck

Specifications:

| Item | Specifications |

| Bore Diameter | 150mm-450mm,Customized |

| Rod Diameter | 120mm-400mm,Customized |

| Stroke | 200-500mm,Customized |

| Working Pressure | 7-45Mpa,Customized |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Tube&Barrel | High tensile cold drawn tube, precision honed for extended seal life |

| Seal Type | Parker,NOK, Hallite GAPI or as customer’s requirement |

| Certificate | ISO9001,CE,SGS. |

| Colour | Yellow,Red,Black,Pink,Customized |

| Packaging | metal case;plywood case;carton or as requirement |

| MOQ | 1pcs,According to products |

| Brand | tianjian or customer’s logo |

| Service | OEM & ODM |

| Production Time | Based on order quantity. normally 30-45days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Mounting Method:

Appliactions:Mining Dump Truck

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Packing & Delivery:

About US:Certificates

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

Our Customers

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 3000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does a lift cylinder handle variations in cylinder size and capacity?

A lift cylinder is designed to handle variations in cylinder size and capacity to accommodate different lifting requirements. Here’s an explanation of how lift cylinders handle these variations:

1. Size and Dimensions:

Lift cylinders come in various sizes and dimensions to suit different applications. The cylinder size refers to its overall dimensions, such as the diameter and length of the cylinder body. Lift cylinders can be manufactured in a range of sizes, allowing for flexibility in selecting the appropriate cylinder size based on the specific lifting needs. Larger cylinders are capable of generating greater lifting force, while smaller cylinders are more compact and suitable for applications with limited space.

2. Capacity and Load Rating:

The capacity of a lift cylinder refers to the maximum load it can lift safely. Lift cylinders are rated for specific load capacities, and it is important to select a cylinder with a suitable capacity for the intended lifting task. Lift cylinders with higher load ratings are designed to handle heavier loads, while cylinders with lower load ratings are suitable for lighter loads. The capacity of the lift cylinder is determined by factors such as its construction, materials, and structural integrity.

3. Hydraulic Pressure:

The hydraulic pressure applied to the lift cylinder affects its lifting capacity and force generation. By adjusting the hydraulic pressure within the system, operators can control the lifting capability of the cylinder. Higher hydraulic pressure results in increased lifting force, allowing the cylinder to handle larger loads. Conversely, lower hydraulic pressure reduces the lifting capacity of the cylinder, making it suitable for lighter loads. The hydraulic pressure can be regulated using control valves or pressure relief valves within the hydraulic system.

4. Application-specific Design:

Lift cylinders are designed to meet the requirements of specific applications. Manufacturers take into consideration factors such as load characteristics, operating conditions, and safety considerations when designing lift cylinders. This ensures that the cylinder size and capacity are matched to the demands of the application, allowing for efficient and safe lifting operations.

5. Customization Options:

In some cases, lift cylinders can be customized to fit specific size or capacity requirements. Manufacturers may offer customization options such as special sizes, load capacity modifications, or additional features to meet unique application needs. Customization allows for a tailored solution that optimizes the performance and efficiency of the lift cylinder in a particular setting.

In summary, lift cylinders handle variations in cylinder size and capacity by offering a range of sizes and load ratings. The hydraulic pressure can be adjusted to match the lifting requirements, and lift cylinders can be customized for specific applications. With their versatility and adaptability, lift cylinders provide efficient and reliable lifting capabilities across a wide range of industries and lifting tasks.

Can lift cylinders be used in manufacturing and production machinery?

Yes, lift cylinders are commonly used in manufacturing and production machinery. Lift cylinders, also known as hydraulic cylinders, are devices that generate linear force and motion through the use of pressurized hydraulic fluid. They are widely employed in various industrial applications for lifting, pushing, pulling, and holding heavy loads.

In manufacturing and production machinery, lift cylinders play a crucial role in providing controlled movement and force for a wide range of tasks. Here are some examples of how lift cylinders are used:

- Material Handling: Lift cylinders are utilized in machinery such as forklifts, cranes, and material handling equipment to lift and transport heavy objects. They allow for precise positioning and movement of loads, improving efficiency and safety in material handling operations.

- Assembly and Automation: Lift cylinders are integrated into assembly lines and automated machinery to perform tasks like part insertion, pressing, and clamping. They provide the necessary force and motion required for assembling components or joining parts together.

- Presses and Punching Machines: Lift cylinders are employed in presses and punching machines to exert force for bending, forming, and shaping materials. These cylinders ensure accurate and consistent results in metalworking processes.

- Industrial Robots: Lift cylinders are used in robotic systems to enable lifting and manipulation of objects. They facilitate the controlled movement of robot arms and end-effectors, allowing robots to perform tasks such as pick-and-place operations, welding, and painting.

Lift cylinders offer several advantages in manufacturing and production machinery. They provide high force capabilities, precise control over movement, compact design, and the ability to operate in various orientations. Furthermore, their hydraulic nature allows for smooth and gradual acceleration and deceleration, reducing the risk of damage to the machinery or the materials being handled.

In conclusion, lift cylinders are extensively utilized in manufacturing and production machinery across different industries. Their versatility, reliability, and ability to generate controlled linear force make them essential components in a wide range of industrial applications.

What is the importance of regular maintenance for lift cylinders?

Regular maintenance for lift cylinders is of utmost importance to ensure their optimal performance, longevity, and safe operation. Here’s an explanation of the importance of regular maintenance for lift cylinders:

1. Safety:

Regular maintenance helps identify and address potential safety issues with lift cylinders. Over time, wear and tear, leaks, or component failures can compromise the integrity and stability of the cylinder. Through regular inspections and maintenance, any safety concerns can be detected early and resolved, reducing the risk of accidents or equipment failures.

2. Performance:

Maintaining lift cylinders at regular intervals helps ensure their consistent performance. By inspecting and servicing the cylinder components, such as seals, rods, and pistons, any issues affecting the cylinder’s efficiency and functionality can be addressed. Properly maintained cylinders are more reliable, provide smoother operation, and deliver the required lifting power consistently.

3. Preventive Measures:

Regular maintenance allows for preventive measures to be taken to avoid major breakdowns or costly repairs. By following a maintenance schedule, potential problems can be identified early and resolved before they escalate. This includes tasks such as lubrication, seal replacement, cleaning, and adjusting hydraulic fluid levels, which can help extend the lifespan of the cylinder and minimize downtime.

4. Cost Savings:

Regular maintenance can lead to significant cost savings in the long run. By addressing minor issues promptly, it helps prevent major failures that require expensive repairs or cylinder replacements. Well-maintained cylinders also tend to have a longer service life, reducing the need for frequent replacements and associated costs.

5. Compliance with Manufacturer’s Recommendations:

Manufacturers often provide specific maintenance guidelines for lift cylinders. Adhering to these recommendations ensures that the cylinders are maintained according to the intended specifications. Regular maintenance helps uphold warranty requirements, maintain compliance with industry standards, and maximize the cylinder’s performance according to the manufacturer’s specifications.

6. System Efficiency:

Lift cylinders are often part of larger hydraulic systems. Regular maintenance of the cylinders helps maintain the overall efficiency of the system. Any issues or inefficiencies in the cylinders can affect the performance of the entire hydraulic system, leading to decreased productivity, increased energy consumption, and potential damage to other system components.

In summary, regular maintenance for lift cylinders is crucial for safety, performance, preventive measures, cost savings, compliance with manufacturer’s recommendations, and system efficiency. By investing in regular inspections, servicing, and adherence to maintenance schedules, lift cylinders can operate reliably, efficiently, and safely throughout their lifespan.

editor by Dream 2024-05-07

China Custom Straight Trip Scissor Lift Hydraulic Cylinders Mining Truck Oil Suspension Nitrogen Cylinder with Best Sales

Product Description

China Manufacturer Mining Dump Truck Spare Parts Front Rear Ride Oil Suspension Nitrogen Hydraulic Cylinder Made in China

Product Description:

Widely used in equipment for Coal&mine,Engineering.

Special structural design, high-strength material use, and special heat treatment and welding processes ensure that the oil cylinder has extremely high fatigue durability under high pressure and heavy load.

The front and rear suspension cylinders can be analyzed and calculated based on the parameters provided by customers, and the stiffness and damping curves required by customers can be designed.

The surface of the piston rod adopts special surface treatment to ensure excellent wear and corrosion resistance of the piston rod.

Select heavy-duty sealing rings to meet the harsh working conditions of the mining area, ensuring excellent dustproof and sealing performance of the oil cylinder.

Select a wide series and high bearing capacity integrated guide ring, with strong lateral force resistance.

The interior of the lifting cylinder can be designed with a buffer structure to avoid excessive impact during lifting and lowering processes.

The steering cylinder can be equipped with a built-in displacement sensor to monitor the cylinder stroke in real-time.

The piston accumulator adopts a dual piston design, with high and low pressure chambers to meet various road conditions.

The reliable sealing structure design of the piston accumulator ensures the separation of oil and gas.

Product Display:

Front suspension cylinder for mining dump truck

Rear suspension cylinder for mining dump truck

Specifications:

| Item | Specifications |

| Bore Diameter | 150mm-450mm,Customized |

| Rod Diameter | 120mm-400mm,Customized |

| Stroke | 200-500mm,Customized |

| Working Pressure | 7-45Mpa,Customized |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Tube&Barrel | High tensile cold drawn tube, precision honed for extended seal life |

| Seal Type | Parker,NOK, Hallite GAPI or as customer’s requirement |

| Certificate | ISO9001,CE,SGS. |

| Colour | Yellow,Red,Black,Pink,Customized |

| Packaging | metal case;plywood case;carton or as requirement |

| MOQ | 1pcs,According to products |

| Brand | tianjian or customer’s logo |

| Service | OEM & ODM |

| Production Time | Based on order quantity. normally 30-45days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Mounting Method:

Appliactions:Mining Dump Truck

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Packing & Delivery:

About US:Certificates

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

Our Customers

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 3000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does a lift cylinder contribute to efficient and reliable lifting?

A lift cylinder plays a crucial role in enabling efficient and reliable lifting operations. Here’s an explanation of how a lift cylinder contributes to efficient and reliable lifting:

1. High Lifting Capacity:

Lift cylinders are specifically designed to provide high lifting capacities. They can generate substantial force to lift heavy loads, making them well-suited for material handling tasks that involve large or bulky items. The high lifting capacity ensures that the cylinder can effectively handle the intended load, contributing to efficient lifting without the need for additional equipment or manual labor.

2. Precise Control:

Lift cylinders offer precise control over the lifting process. By regulating the flow and pressure of hydraulic fluid, operators can achieve accurate positioning and controlled movements. This level of control allows for efficient and precise placement of the load, reducing the risk of damage to the load or surrounding objects. The precise control also enables operators to optimize the lifting process, saving time and effort.

3. Smooth and Stable Operation:

Lift cylinders provide smooth and stable operation during lifting operations. The hydraulic system ensures that the lifting motion is steady and controlled, minimizing jerking or sudden movements. This smooth operation is important for the safe handling of delicate or fragile materials. It also enhances operator confidence and reduces the risk of accidents, contributing to reliable lifting performance.

4. Quick Response Time:

Lift cylinders offer quick response times, allowing for efficient and timely lifting operations. When activated, the hydraulic system quickly directs fluid into the cylinder, initiating the lifting motion. This rapid response time reduces downtime and enables operators to complete lifting tasks more efficiently.

5. Durability and Reliability:

Lift cylinders are built to withstand the demands of heavy-duty lifting operations. They are constructed with durable materials and designed to handle repetitive lifting tasks over extended periods. The robust construction and reliable performance of lift cylinders ensure that they can consistently deliver efficient lifting performance without frequent breakdowns or malfunctions.

6. Safety Features:

Lift cylinders often incorporate safety features to enhance reliability during lifting operations. These features can include load-holding valves, pressure relief valves, and fail-safe mechanisms. Load-holding valves prevent the load from dropping in the event of hydraulic pressure loss, ensuring the load remains securely lifted. Pressure relief valves protect the system from excessive pressure, preventing potential damage. Fail-safe mechanisms provide additional safety by engaging in the event of a system failure or power loss. The presence of these safety features contributes to reliable and safe lifting operations.

7. Integration with Control Systems:

Advanced lift cylinders can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs). This integration allows for automation and optimized control of the lifting process. By incorporating sensors, feedback mechanisms, and pre-programmed sequences, the lift cylinder can operate efficiently and reliably with minimal operator intervention.

In summary, a lift cylinder contributes to efficient and reliable lifting through its high lifting capacity, precise control, smooth and stable operation, quick response time, durability and reliability, incorporation of safety features, and integration with control systems. These features and capabilities ensure that the lifting process is efficient, accurate, and safe, thereby enhancing overall lifting performance.

Can lift cylinders be used in hydraulic presses for material forming?

Yes, lift cylinders can be used in hydraulic presses for material forming. Hydraulic presses are widely employed in manufacturing processes that involve shaping, bending, or compressing materials such as metal, plastic, or rubber.

Lift cylinders, also known as hydraulic cylinders, play a crucial role in hydraulic presses by providing the force required for material forming. Here’s how lift cylinders are utilized in this context:

- Force Generation: Lift cylinders are responsible for generating the force necessary to exert pressure on the material being formed. They convert hydraulic energy into mechanical force, enabling the press to shape or mold the material according to the desired specifications.

- Stroke Length: Lift cylinders have an adjustable stroke length, allowing them to accommodate different material forming requirements. By modifying the stroke length, the press can apply varying degrees of force and control to achieve the desired shape and dimensions of the formed material.

- Control and Precision: Lift cylinders offer precise control over the force and movement in hydraulic presses. The hydraulic system controlling the cylinders allows for accurate adjustment and regulation of the pressure, speed, and timing of the forming process. This control ensures consistent and precise material forming results.

- Die Mounting: Lift cylinders are employed in the mounting of dies or tooling within the hydraulic press. The cylinders provide the necessary lifting and lowering action to secure the dies in place and facilitate their proper alignment with the material being formed. This ensures accurate and repeatable forming operations.

- Safety Features: Hydraulic presses incorporating lift cylinders often include safety features such as pressure relief valves, emergency stop controls, and overload protection. These features help safeguard operators and prevent damage to the press or the formed material.

The use of lift cylinders in hydraulic presses for material forming offers several advantages. They provide the high force capability required for effective shaping and forming of various materials. The adjustable stroke length and precise control allow for versatility and customization, accommodating different forming needs. The integration of safety features ensures safe operation and protects both the equipment and personnel.

In conclusion, lift cylinders are suitable for use in hydraulic presses for material forming. Their ability to generate force, adjust stroke length, and provide precise control makes them essential components in achieving accurate, efficient, and reliable material forming processes.

What is a lift cylinder and how does it function in hydraulic systems?

A lift cylinder, also known as a hydraulic lift cylinder or hydraulic lifting cylinder, is a device used in hydraulic systems to generate linear motion and provide lifting force. It is a type of hydraulic actuator that converts hydraulic pressure into mechanical force to lift heavy loads. Here’s an explanation of what a lift cylinder is and how it functions in hydraulic systems:

A lift cylinder consists of a cylindrical barrel, a piston, and a rod. The barrel is a hollow tube that houses the piston and allows fluid to flow in and out. The piston is a cylindrical component that separates the barrel into two chambers. The rod, attached to the piston, extends from the cylinder to connect with the load or the mechanism being lifted.

The lift cylinder operates based on the principles of Pascal’s law, which states that pressure exerted on a fluid in a confined space is transmitted equally in all directions. Here’s how a lift cylinder functions:

1. Extension:

When pressurized hydraulic fluid enters one side of the cylinder (the chamber behind the piston), it applies force on the piston, causing it to move in the direction of the load. This movement extends the rod outward, lifting or pushing the load.

2. Retraction:

Conversely, when the hydraulic fluid is supplied to the other side of the cylinder (the chamber in front of the piston), the pressure differential causes the piston to move in the opposite direction. This retracts the rod, lowering or pulling the load.

3. Control Valve:

The flow of hydraulic fluid into and out of the lift cylinder is controlled by a directional control valve. The valve regulates the direction and amount of fluid entering the cylinder, determining whether the cylinder extends or retracts. This control allows for precise and controlled lifting and lowering of the load.

4. Force and Load Capacity:

The force generated by the lift cylinder is determined by the hydraulic pressure applied to the piston and the effective area of the piston. By increasing or decreasing the hydraulic pressure, the lifting force can be adjusted to meet the specific load requirements.

5. Application:

Lift cylinders are widely used in various hydraulic systems, including hydraulic lifts, cranes, forklifts, dump trucks, and construction equipment. They provide the necessary force to lift heavy objects, perform material handling tasks, and support heavy loads in a controlled and efficient manner.

In summary, a lift cylinder is a hydraulic actuator that converts hydraulic pressure into mechanical force for lifting heavy loads. It functions by utilizing hydraulic fluid pressure to move the piston and extend or retract the rod, enabling the lifting or lowering of the load. The control valve regulates the fluid flow, and the force generated by the lift cylinder is determined by the hydraulic pressure and piston area. Lift cylinders find extensive applications in hydraulic systems across various industries.

editor by CX 2024-04-15

China Best Sales Mining Dump Truck Parts Rear Suspension Hydraulic Oil Cylinder From Factory Supply vacuum pump and compressor

Product Description

Mining dump truck parts rear suspension hydraulic oil cylinder from factory supply

Product Description

Product Description:

| Work Press | 7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

| Material | Aluminum,Cast Iron,45mnb Steel,Stainless Steel, carbon steel |

| Bore Size | 150mm-450mm, Customizable |

| Rod size | 120mm-4000mm, Customizable |

| Stroke length | ≤400mm, Customizable |

| Paint Color | Red,Yellow,Blue,Brown,Customizable |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,Customizable |

| Warrenty | 18 months |

| MOQ | 1 pcs |

| Delivery Time | 7-15 Days,Also depands on specific demands |

| Certification | ISO9001,CE, SGS |

Appliactions:

Application:mining truck

Detailed Photos

Product Display:

Quality Assurance

Quality Assurance

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Mounting Method:

Company Profile

Our Factory:

About US:

Tianjian Hydraulic. is a leader in the engineering design and manufacture of high pressure hydraulic cylinders that are widely used in the fields of mining, metallurgy, construction machinery, marine, offshore, water engineering, wind power, hydraulic press, agricultural machinery, and so on.

The Tianjian team has almost 8 years experience delivering innovative and dependable solutions to meet OEM high pressure hydraulic cylinder needs.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

Packing & Delivery:

FAQ

FAQ:

1, What does your company do?

A: we are a professional supplier of high quality hydraulic cylinders for more than 8 years.

2, Are you a manufacture or a trading company?

A: We are a manufacturer. Warmly welcome to visit us!

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 15-60 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. Can be negonatied.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 600/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What advancements in hydraulic cylinder technology have improved sealing and reliability?

Advancements in hydraulic cylinder technology have continuously contributed to improving sealing and reliability in hydraulic systems. These advancements aim to address common challenges such as leakage, wear, and failure of seals, ensuring optimal performance and longevity. Here are several key advancements that have significantly improved sealing and reliability in hydraulic cylinders:

1. High-Performance Sealing Materials:

– The development of advanced sealing materials has greatly improved the sealing capabilities of hydraulic cylinders. Traditional sealing materials like rubber have been replaced or enhanced with high-performance materials such as polyurethane, PTFE (polytetrafluoroethylene), and various composite materials. These materials offer superior resistance to wear, temperature, and chemical degradation, resulting in improved sealing performance and extended seal life.

2. Enhanced Seal Designs:

– Advancements in seal designs have focused on improving sealing efficiency and reliability. Innovative seal profiles, such as lip seals, wipers, and scrapers, have been developed to optimize fluid retention and prevent contamination. These designs provide better sealing performance, minimizing the risk of fluid leakage and maintaining system integrity. Additionally, improved seal geometries and manufacturing techniques ensure tighter tolerances, reducing the potential for seal failure due to misalignment or extrusion.

3. Integrated Seal and Bearing Systems:

– Hydraulic cylinders now incorporate integrated seal and bearing systems, where the sealing elements also serve as bearing surfaces. This design approach reduces the number of components and potential failure points, improving overall reliability. By integrating seals and bearings, the risk of seal damage or displacement due to excessive loads or misalignment is minimized, resulting in enhanced sealing performance and increased reliability.

4. Advanced Coatings and Surface Treatments:

– The application of advanced coatings and surface treatments to hydraulic cylinder components has significantly improved sealing and reliability. Coatings such as chrome plating or ceramic coatings enhance surface hardness, wear resistance, and corrosion resistance. These surface treatments provide a smoother and more durable surface for seals to operate against, reducing friction and improving sealing performance. Moreover, specialized coatings can also provide self-lubricating properties, reducing the need for additional lubrication and enhancing reliability.

5. Sealing System Monitoring and Diagnostic Technologies:

– The integration of monitoring and diagnostic technologies in hydraulic systems has revolutionized seal performance and reliability. Sensors and monitoring systems can detect and alert operators to potential seal failures or leaks before they escalate. Real-time monitoring of pressure, temperature, and seal performance parameters allows for proactive maintenance and early intervention, preventing costly downtime and ensuring optimal sealing and reliability.

6. Computational Modeling and Simulation:

– Computational modeling and simulation techniques have played a significant role in advancing hydraulic cylinder sealing and reliability. These tools enable engineers to analyze and optimize seal designs, fluid flow dynamics, and contact stresses. By simulating various operating conditions, potential issues such as seal extrusion, wear, or leakage can be identified and mitigated early in the design phase, resulting in improved sealing performance and enhanced reliability.

7. Systematic Maintenance Practices:

– Advances in hydraulic cylinder technology have also emphasized the importance of systematic maintenance practices to ensure sealing and overall system reliability. Regular inspection, lubrication, and replacement of seals, as well as routine system flushing and filtration, help prevent premature seal failure and optimize sealing performance. Implementing preventive maintenance schedules and adhering to recommended service intervals contribute to extended seal life and enhanced reliability.

In summary, advancements in hydraulic cylinder technology have led to significant improvements in sealing and reliability. High-performance sealing materials, enhanced seal designs, integrated seal and bearing systems, advanced coatings and surface treatments, sealing system monitoring and diagnostics, computational modeling and simulation, and systematic maintenance practices have all played key roles in achieving optimal sealing performance and increased reliability. These advancements have resulted in more efficient and dependable hydraulic systems, minimizing leakage, wear, and failure of seals, and ultimately improving the overall performance and longevity of hydraulic cylinders in diverse applications.

Ensuring Stable Performance of Hydraulic Cylinders Under Fluctuating Loads

Hydraulic cylinders are designed to provide stable performance even under fluctuating loads. They achieve this through various mechanisms and features that allow for efficient load control and compensation. Let’s explore how hydraulic cylinders ensure stable performance under fluctuating loads:

- Piston Design: The piston inside the hydraulic cylinder plays a crucial role in load control. It is typically equipped with seals and rings that prevent leakage of hydraulic fluid and ensure effective transfer of force. The piston design may incorporate features such as stepped or tandem pistons, which provide enhanced load-bearing capabilities and improved stability by distributing the load across multiple surfaces.

- Cylinder Cushioning: Hydraulic cylinders often incorporate cushioning mechanisms to minimize the impact and shock caused by fluctuating loads. Cushioning can be achieved through various methods, such as adjustable cushion screws, hydraulic cushioning valves, or elastomeric cushioning rings. These mechanisms slow down the piston’s movement near the end of the stroke, reducing the impact and preventing sudden stops that could lead to instability.

- Pressure Compensation: Fluctuating loads can result in pressure variations within the hydraulic system. To ensure stable performance, hydraulic cylinders are equipped with pressure compensation mechanisms. These mechanisms maintain a consistent pressure level in the system, regardless of load changes. Pressure compensation can be achieved through the use of pressure relief valves, compensating pistons, or pressure-compensated flow control valves.

- Flow Control: Hydraulic cylinders often incorporate flow control valves to regulate the speed of the cylinder’s movement. By controlling the flow rate of hydraulic fluid, the cylinder’s motion can be adjusted to match the changing load conditions. Flow control valves allow for smooth and controlled movement, preventing abrupt changes that could lead to instability.

- Feedback Systems: To ensure stable performance under fluctuating loads, hydraulic cylinders can be integrated with feedback systems. These systems provide real-time information on the cylinder’s position, velocity, and force. By continuously monitoring these parameters, the hydraulic system can make immediate adjustments to maintain stability and compensate for load fluctuations. Feedback systems can include position sensors, pressure sensors, or load sensors, depending on the specific application.

- Proper Sizing and Selection: Ensuring stable performance under fluctuating loads starts with proper sizing and selection of hydraulic cylinders. It is crucial to choose cylinders with appropriate bore size, rod diameter, and stroke length to match the anticipated load conditions. Oversized or undersized cylinders can lead to instability and reduced performance. Proper sizing also involves considering factors such as the required force, speed, and duty cycle of the application.

In summary, hydraulic cylinders ensure stable performance under fluctuating loads through features such as piston design, cushioning mechanisms, pressure compensation, flow control, feedback systems, and proper sizing and selection. These mechanisms and considerations allow hydraulic cylinders to provide consistent and controlled movement, even in dynamic load conditions, resulting in reliable and stable performance.

How do hydraulic cylinders contribute to the efficiency of heavy machinery like excavators?

Hydraulic cylinders play a crucial role in enhancing the efficiency and performance of heavy machinery, such as excavators. These powerful hydraulic actuators enable excavators to perform various tasks efficiently and effectively. Here’s a detailed explanation of how hydraulic cylinders contribute to the efficiency of heavy machinery like excavators:

1. Force and Power:

– Hydraulic cylinders provide the necessary force and power required for the excavation process. They convert hydraulic energy from the hydraulic fluid into linear mechanical force, allowing the excavator to exert significant pushing and pulling forces. The force generated by hydraulic cylinders enables the digging arm or boom of the excavator to penetrate and break through tough materials, such as soil, rocks, or concrete, with ease and efficiency.

2. Precise Control:

– Hydraulic cylinders offer precise control over the movement of excavator components. By regulating the flow of hydraulic fluid to the cylinders, operators can control the speed, direction, and positioning of the excavator’s arm, boom, bucket, and other attachments. This precise control allows operators to perform delicate operations, such as fine grading or precise material placement, with accuracy and efficiency.

3. Versatility and Adaptability:

– Hydraulic cylinders enable excavators to perform a wide range of tasks by facilitating the quick and easy interchangeability of attachments. Excavators can be equipped with various specialized attachments, including buckets, breakers, grapples, and augers, which can be efficiently connected and disconnected using hydraulic cylinders. This versatility and adaptability enhance the efficiency of excavators by enabling them to tackle different tasks without the need for extensive manual adjustments or downtime.

4. Increased Productivity:

– The power and control provided by hydraulic cylinders significantly increase the productivity of excavators. Excavators equipped with hydraulic cylinders can complete tasks more quickly and efficiently compared to manual or mechanically-driven machinery. The precise control over movements allows for faster cycle times, reduced idle time, and improved overall productivity on the worksite.

5. Enhanced Digging and Lifting Capabilities:

– Hydraulic cylinders enable excavators to perform digging and lifting operations with enhanced capabilities. The force generated by hydraulic cylinders allows excavators to dig deeper and lift heavier loads compared to other types of machinery. This increased digging and lifting capacity contributes to the efficiency of excavators by reducing the number of passes required to complete a task and improving overall productivity.

6. Durability and Reliability:

– Hydraulic cylinders are designed to withstand heavy loads, challenging operating conditions, and frequent use. They are built with robust materials, such as high-strength steel, and undergo stringent quality control measures during manufacturing. The durability and reliability of hydraulic cylinders ensure that excavators can operate efficiently even in demanding environments, minimizing downtime and maximizing productivity.

7. Energy Efficiency:

– Hydraulic systems, including hydraulic cylinders, are known for their energy efficiency. Hydraulic cylinders can deliver high force outputs while consuming relatively low amounts of hydraulic fluid. This energy efficiency translates to lower fuel consumption and reduced operating costs for excavators. The efficient use of hydraulic power contributes to the overall efficiency and sustainability of heavy machinery operations.

8. Safety:

– Hydraulic cylinders play a vital role in ensuring the safety of excavator operations. They provide controlled and predictable movements, reducing the risk of sudden or uncontrolled motions. The precise control offered by hydraulic cylinders allows operators to perform tasks safely and accurately, minimizing the chances of accidents or damage to the machinery or surrounding environment.

Overall, hydraulic cylinders are essential components that significantly contribute to the efficiency of heavy machinery like excavators. By providing force, precise control, versatility, increased productivity, enhanced capabilities, durability, energy efficiency, and safety, hydraulic cylinders enable excavators to perform a wide range of tasks efficiently and effectively in various industries, including construction, mining, and landscaping.

editor by CX 2023-12-22

China high quality Front Suspension Nitrogen Hydraulic Cylinder for Mining Truck Spare Parts with ISO Made in China vacuum pump adapter

Product Description

Front Suspension Nitrogen Hydraulic Cylinder for Mining Truck Spare Parts with ISO Made in China

Product Description:

Widely used in equipment for Coal&mine,Engineering.

Special structural design, high-strength material use, and special heat treatment and welding processes ensure that the oil cylinder has extremely high fatigue durability under high pressure and heavy load.

The front and rear suspension cylinders can be analyzed and calculated based on the parameters provided by customers, and the stiffness and damping curves required by customers can be designed.

The surface of the piston rod adopts special surface treatment to ensure excellent wear and corrosion resistance of the piston rod.

Select heavy-duty sealing rings to meet the harsh working conditions of the mining area, ensuring excellent dustproof and sealing performance of the oil cylinder.

Select a wide series and high bearing capacity integrated guide ring, with strong lateral force resistance.

The interior of the lifting cylinder can be designed with a buffer structure to avoid excessive impact during lifting and lowering processes.

The steering cylinder can be equipped with a built-in displacement sensor to monitor the cylinder stroke in real-time.

The piston accumulator adopts a dual piston design, with high and low pressure chambers to meet various road conditions.

The reliable sealing structure design of the piston accumulator ensures the separation of oil and gas.

Product Display:

Front suspension cylinder for mining dump truck

Rear suspension cylinder for mining dump truck

Specifications:

| Item | Specifications |

| Bore Diameter | 150mm-450mm,Customized |

| Rod Diameter | 120mm-400mm,Customized |

| Stroke | 200-500mm,Customized |

| Working Pressure | 7-45Mpa,Customized |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Tube&Barrel | High tensile cold drawn tube, precision honed for extended seal life |

| Seal Type | Parker,NOK, Hallite GAPI or as customer’s requirement |

| Certificate | ISO9001,CE,SGS. |

| Colour | Yellow,Red,Black,Pink,Customized |

| Packaging | metal case;plywood case;carton or as requirement |

| MOQ | 1pcs,According to products |

| Brand | tianjian or customer’s logo |

| Service | OEM & ODM |

| Production Time | Based on order quantity. normally 30-45days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Mounting Method:

Appliactions:Mining Dump Truck

Other Products:

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Packing & Delivery:

About US:Certificates

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

Our Customers

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts.

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 5200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do hydraulic cylinders contribute to the overall cost-effectiveness of industrial processes?

Hydraulic cylinders play a crucial role in enhancing the overall cost-effectiveness of industrial processes. They offer several advantages and contribute to increased productivity, improved efficiency, reduced maintenance costs, and enhanced operational performance. Here’s a detailed explanation of how hydraulic cylinders contribute to the cost-effectiveness of industrial processes:

1. High Power Density:

– Hydraulic cylinders provide a high power-to-weight ratio, allowing them to generate substantial force in a compact design. This power density enables the use of smaller and lighter equipment, reducing material and manufacturing costs, and increasing the efficiency of industrial processes.

2. Precise Force and Position Control:

– Hydraulic cylinders offer precise force and position control, allowing for accurate movement and positioning of machinery or workpieces. This level of control enhances process efficiency, reduces material waste, and improves overall product quality. Precise force control also minimizes the risk of equipment damage, further reducing maintenance and repair costs.

3. High Load Handling Capacity:

– Hydraulic cylinders are known for their ability to handle high loads. They can exert significant force, making them suitable for heavy-duty industrial applications. By efficiently handling heavy loads, hydraulic cylinders contribute to increased productivity and throughput, reducing the need for additional equipment and streamlining industrial processes.

4. Flexibility and Versatility:

– Hydraulic cylinders offer a high degree of flexibility and versatility in industrial processes. They can be easily integrated into various types of machinery and equipment, allowing for diverse applications. This adaptability reduces the need for specialized equipment, resulting in cost savings and increased operational efficiency.

5. Energy Efficiency:

– Hydraulic systems, including hydraulic cylinders, can be designed to operate with high energy efficiency. By utilizing efficient hydraulic circuit designs, advanced control systems, and energy recovery mechanisms, hydraulic cylinders minimize energy waste and reduce operational costs. Energy-efficient hydraulic systems also contribute to a more sustainable and environmentally friendly industrial operation.

6. Durability and Longevity:

– Hydraulic cylinders are built to withstand demanding industrial environments and heavy usage. They are constructed with robust materials and undergo stringent quality control measures to ensure durability and longevity. Their ability to withstand harsh conditions and repetitive motion reduces the need for frequent replacements, minimizing downtime and maintenance costs.

7. Reduced Maintenance Requirements:

– Hydraulic cylinders require relatively low maintenance compared to other types of actuators. Properly designed hydraulic systems with efficient filtration and contamination control mechanisms can prevent damage to the cylinders and extend their service life. Reduced maintenance requirements result in lower downtime, decreased labor costs, and improved cost-effectiveness of industrial processes.

8. System Integration and Automation:

– Hydraulic cylinders can be seamlessly integrated into automated industrial processes. By incorporating hydraulic cylinders into automated systems, tasks can be performed with precision and repeatability, reducing human error and optimizing efficiency. Automation also allows for continuous operation, increasing productivity and overall cost-effectiveness.

9. Cost-Effective Replacement:

– In situations where hydraulic cylinders require replacement or repair, the cost-effectiveness of the process is still maintained. Hydraulic cylinders are typically modular in design, allowing for easy replacement of individual components or complete units. This modularity reduces downtime and associated costs, as only the affected components need to be replaced, rather than the entire system.

In summary, hydraulic cylinders contribute to the overall cost-effectiveness of industrial processes through their high power density, precise control capabilities, high load handling capacity, flexibility, energy efficiency, durability, reduced maintenance requirements, system integration, and cost-effective replacement options. Their ability to enhance productivity, efficiency, and operational performance while minimizing maintenance and downtime costs makes hydraulic cylinders a valuable component in various industrial applications.

Integration of Hydraulic Cylinders with Equipment Requiring Rapid and Dynamic Movements

Hydraulic cylinders can indeed be integrated with equipment that requires rapid and dynamic movements. While hydraulic systems are generally known for their ability to provide high force and precise control, they can also be designed and optimized for applications that demand fast and dynamic motion. Let’s explore how hydraulic cylinders can be integrated with such equipment:

- High-Speed Hydraulic Systems: Hydraulic cylinders can be part of high-speed hydraulic systems designed specifically for rapid and dynamic movements. These systems incorporate features such as high-flow valves, optimized hydraulic circuitry, and responsive control systems. By carefully engineering the system components and hydraulic parameters, it is possible to achieve the desired speed and responsiveness, enabling the equipment to perform rapid movements.

- Valve Control: The control of hydraulic cylinders plays a crucial role in achieving rapid and dynamic movements. Proportional or servo valves can be used to precisely control the flow of hydraulic fluid into and out of the cylinder. These valves offer fast response times and precise flow control, allowing for rapid acceleration and deceleration of the cylinder’s piston. By adjusting the valve settings and optimizing the control algorithms, equipment can be designed to execute dynamic movements with high speed and accuracy.

- Optimized Cylinder Design: The design of hydraulic cylinders can be optimized to facilitate rapid and dynamic movements. Lightweight materials, such as aluminum alloys or composite materials, can be used to reduce the moving mass of the cylinder, enabling faster acceleration and deceleration. Additionally, the cylinder’s internal components, such as the piston and seals, can be designed for low friction to minimize energy losses and enhance responsiveness. These design optimizations contribute to the overall speed and dynamic performance of the equipment.

- Accumulator Integration: Hydraulic accumulators can be integrated into the system to enhance the dynamic capabilities of hydraulic cylinders. Accumulators store pressurized hydraulic fluid, which can be rapidly released to supplement the flow from the pump during high-demand situations. This stored energy can provide an extra boost of power, allowing for faster and more dynamic movements. By strategically sizing and configuring the accumulator, the system can be optimized for the specific rapid and dynamic requirements of the equipment.

- System Feedback and Control: To achieve precise and dynamic movements, hydraulic systems can incorporate feedback sensors and advanced control algorithms. Position sensors, such as linear potentiometers or magnetostrictive sensors, provide real-time position feedback of the hydraulic cylinder. This information can be used in closed-loop control systems to maintain precise positioning and execute rapid movements. Advanced control algorithms can optimize the control signals sent to the valves, ensuring smooth and dynamic motion while minimizing overshooting or oscillations.

In summary, hydraulic cylinders can be integrated with equipment that requires rapid and dynamic movements by utilizing high-speed hydraulic systems, employing responsive valve control, optimizing cylinder design, integrating accumulators, and incorporating feedback sensors and advanced control algorithms. These measures enable hydraulic systems to deliver the speed, responsiveness, and precision necessary for equipment operating in dynamic environments. By leveraging the capabilities of hydraulic cylinders, manufacturers can design and integrate systems that meet the requirements of applications demanding rapid and dynamic movements.

Can hydraulic cylinders be customized for specific equipment or attachment needs?

Yes, hydraulic cylinders can be customized to meet specific equipment or attachment needs. Hydraulic cylinder manufacturers often offer customization options to ensure that the cylinders meet the unique requirements of different applications. Here’s a detailed explanation of how hydraulic cylinders can be customized for specific equipment or attachment needs:

1. Size and Configuration:

– Hydraulic cylinders can be customized in terms of size and configuration to fit specific equipment or attachment requirements. The dimensions of the cylinder, such as bore size, rod diameter, and stroke length, can be tailored to match the available space and the desired force or movement requirements. Additionally, the mounting style and orientation of the cylinder can be customized to ensure proper integration with the equipment or attachment.

2. Operating Pressure and Force:

– The operating pressure and force capabilities of hydraulic cylinders can be customized to suit the specific equipment or attachment needs. Different applications may require different force outputs, and hydraulic cylinder manufacturers can design and manufacture cylinders with the appropriate piston area and pressure ratings to meet those requirements. Customization in this aspect ensures optimal performance and efficiency for the particular equipment or attachment.

3. Stroke Length:

– The stroke length of a hydraulic cylinder refers to the distance the piston can travel from fully retracted to fully extended. Customization of the stroke length allows the hydraulic cylinder to accommodate the specific range of motion required by the equipment or attachment. By adjusting the stroke length, the cylinder can be tailored to deliver the necessary extension and retraction capabilities for efficient operation.

4. Mounting Options:

– Hydraulic cylinders can be customized with various mounting options to facilitate easy installation and integration with specific equipment or attachments. Different applications may require different mounting styles, such as flange mounts, trunnion mounts, or clevis mounts. Manufacturers can provide customized mounting options to ensure proper alignment, stability, and functionality when the cylinder is connected to the equipment or attachment.

5. Sealing and Material Options:

– The sealing system of a hydraulic cylinder is crucial for preventing fluid leakage and maintaining the cylinder’s integrity. Hydraulic cylinder manufacturers offer customization options for sealing materials, such as different types of seals and seal configurations, to suit specific equipment or attachment needs. Additionally, customization of cylinder materials, such as selecting corrosion-resistant materials or specialized coatings, can enhance the cylinder’s durability and performance in specific operating environments.

6. Integration with Control Systems:

– In certain applications, hydraulic cylinders may need to be integrated with sophisticated control systems or automation technologies. Customization can involve incorporating sensors, position feedback devices, or other control elements into the hydraulic cylinder design to enable seamless integration with the overall equipment or attachment control system. This customization ensures precise control, monitoring, and synchronization of the hydraulic cylinder’s movements within the specific application.

7. Specialized Features or Accessories:

– Hydraulic cylinder customization can also involve incorporating specialized features or accessories to meet unique equipment or attachment needs. This may include the integration of safety features, such as pressure relief valves or load-holding valves, or the addition of specific ports or fittings for auxiliary functions or attachments. Customization allows hydraulic cylinders to be tailored to the specific requirements and functionalities of the equipment or attachment.

By offering customization options, hydraulic cylinder manufacturers can provide solutions that precisely match the needs of different equipment or attachment applications. Customized hydraulic cylinders ensure optimal performance, efficiency, and integration, enhancing the overall functionality and productivity of the equipment or attachment. It is important to work closely with experienced manufacturers or hydraulic system specialists to determine the specific customization requirements and ensure the successful implementation of customized hydraulic cylinders.

editor by CX 2023-11-15

China wholesaler Suspension Lift Tie Rod Hydraulic Cylinder with Safe Valve vacuum pump belt

Product Description

Specifications:

| Product Name | HSG Series Hydraulic Cylinder |

| Work Press | 7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

| Material | Aluminum, Cast Iron,45mnb Steel, Stainless Steel |

| Bore Size | 40mm–320mm, Customizable |

| Shaft Diameter | 20mm–220mm, Customizable |

| Stroke Length | 30mm–14100mm, Customizable |

| Rod Surface Hardness | HRC48-54 |

| Operating Temperature | -40°C to +120 °C |

| Paint Color | Black, Yellow, Blue, Brown, Customizable |

| Service | OEM&ODM |

| Warranty | 1 Year |

| MOQ | 1 Piece |

| Delivery Time | 7-15 Days, Also depending on specific demands |

| Certification | ISO9001,CE |

| Capacity | 50,000Pcs per year |

Product Display:

Mounting:

Working Flow: About Us

Tongte designs and manufactures durable, heavy-duty hydraulic products and accessories and offers lifecycle services to them. We constantly develop our machine base and operations to meet customer-specific needs and remain leaders in the industry. Beyond all else, we want to be the trusted, groundbreaking partner our customers truly need.

In addition to the customized cylinders, CHINAMFG offers hydraulic power units, Electric-Hydraulic linear actuators, piston accumulators, system configurations, and versatile services such as repair and manufacturing services. The modern production facilities are located in HangZhou, ZheJiang (China) where production started in 2001. The core values of Tongke guiding its business strongly are commitment, sustainability, interaction, and customer-first.

We possess over 20 years of experience in the industry and extensive global market experience, our customers are located all over the world, and we truly commit to the customers’ needs – these are the success factors of our family-owned company. Our vision is to grow and expand the business further into global markets.

FAQ:

Q1: What does your company do?

A: we are a supplier of high-quality hydraulic products including Hydraulic Cylinders, Hydraulic Power packs, Hydraulic Linear, and other Hydraulic components.

Q2:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q3:Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, and 15-30 working days if we don’t. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What is your warranty policy?

A: All our products are warranted for 1 full year from the date of delivery against defects in materials and workmanship. Each individual product will be strictly inspected on our factory QC Process

System before shipment. We also have a Customer Service team to respond to customers’ questions within 12 hours.

| Certification: | ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

How does a lift cylinder contribute to efficient and reliable lifting?

A lift cylinder plays a crucial role in enabling efficient and reliable lifting operations. Here’s an explanation of how a lift cylinder contributes to efficient and reliable lifting:

1. High Lifting Capacity:

Lift cylinders are specifically designed to provide high lifting capacities. They can generate substantial force to lift heavy loads, making them well-suited for material handling tasks that involve large or bulky items. The high lifting capacity ensures that the cylinder can effectively handle the intended load, contributing to efficient lifting without the need for additional equipment or manual labor.

2. Precise Control:

Lift cylinders offer precise control over the lifting process. By regulating the flow and pressure of hydraulic fluid, operators can achieve accurate positioning and controlled movements. This level of control allows for efficient and precise placement of the load, reducing the risk of damage to the load or surrounding objects. The precise control also enables operators to optimize the lifting process, saving time and effort.

3. Smooth and Stable Operation:

Lift cylinders provide smooth and stable operation during lifting operations. The hydraulic system ensures that the lifting motion is steady and controlled, minimizing jerking or sudden movements. This smooth operation is important for the safe handling of delicate or fragile materials. It also enhances operator confidence and reduces the risk of accidents, contributing to reliable lifting performance.

4. Quick Response Time:

Lift cylinders offer quick response times, allowing for efficient and timely lifting operations. When activated, the hydraulic system quickly directs fluid into the cylinder, initiating the lifting motion. This rapid response time reduces downtime and enables operators to complete lifting tasks more efficiently.

5. Durability and Reliability:

Lift cylinders are built to withstand the demands of heavy-duty lifting operations. They are constructed with durable materials and designed to handle repetitive lifting tasks over extended periods. The robust construction and reliable performance of lift cylinders ensure that they can consistently deliver efficient lifting performance without frequent breakdowns or malfunctions.

6. Safety Features:

Lift cylinders often incorporate safety features to enhance reliability during lifting operations. These features can include load-holding valves, pressure relief valves, and fail-safe mechanisms. Load-holding valves prevent the load from dropping in the event of hydraulic pressure loss, ensuring the load remains securely lifted. Pressure relief valves protect the system from excessive pressure, preventing potential damage. Fail-safe mechanisms provide additional safety by engaging in the event of a system failure or power loss. The presence of these safety features contributes to reliable and safe lifting operations.

7. Integration with Control Systems:

Advanced lift cylinders can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs). This integration allows for automation and optimized control of the lifting process. By incorporating sensors, feedback mechanisms, and pre-programmed sequences, the lift cylinder can operate efficiently and reliably with minimal operator intervention.

In summary, a lift cylinder contributes to efficient and reliable lifting through its high lifting capacity, precise control, smooth and stable operation, quick response time, durability and reliability, incorporation of safety features, and integration with control systems. These features and capabilities ensure that the lifting process is efficient, accurate, and safe, thereby enhancing overall lifting performance.

Can lift cylinders be used in construction equipment like cranes?

Yes, lift cylinders are commonly used in construction equipment, including cranes. Here’s an explanation of their utilization in this context:

Lift cylinders play a crucial role in the lifting and positioning operations of construction equipment, providing the necessary force and control to handle heavy loads and perform various construction tasks.

1. Mobile Cranes:

Lift cylinders are integral components of mobile cranes, such as hydraulic truck cranes and rough terrain cranes. These cylinders are typically employed in the boom and jib systems of the crane. By extending or retracting the lift cylinders, the crane can raise or lower the boom or jib, allowing for vertical lifting and horizontal reach. Lift cylinders enable precise control over the crane’s lifting capacity, height, and reach, making them essential for safe and efficient construction operations.

2. Tower Cranes: