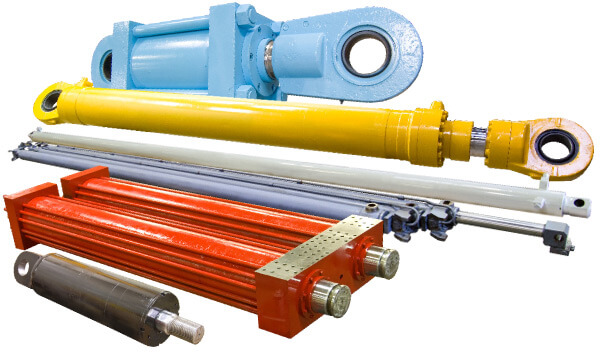

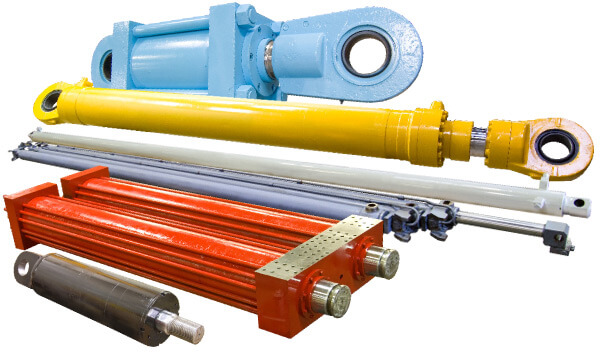

Product Description

Products Description

|

Product Name |

HSG Series Hydraulic Cylinder |

|||

|

Work Press |

7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

|||

|

Material |

Aluminum,Cast Iron,45mnb Steel,Stainless Steel |

|||

|

Bore Size |

40mm–320mm,Customizable |

|||

|

Shaft Diameter |

20mm–220mm,Customizable |

|||

|

Stroke Length |

30mm–14100mm,Customizable |

|||

|

Rod Surface Hardness |

HRC48-54 |

|||

|

Paint Color |

Black,Yellow,Blue,Brown,Customizable |

|||

|

Mounting |

Earring,Flange,Clevis.Foot,Trunnion,Customizable |

|||

|

Warrenty |

1 Year |

|||

|

MOQ |

1 Piece |

|||

|

Delivery Time |

7-15 Days,Also depands on specific demands |

|||

|

Certification |

ISO9001,CE |

|||

Company Profile

QIANGLIN HYDRAULIC MACHINERY CO., LTD

| QiangLin is a professional hydraulic equipment manufacturer, mainly engaged in hydraulic system design, manufacture, installation, transformation, sales, and technical services. Our manufacturing facilities are certified to the ISO 9001 standard. We are an approved supplier to many equipment manufacturers in China. We are also partners with many customers from America, Canada, Australia, Germany, England, and other European Countries. Product quality, shorter delivery time, and customer satisfaction are our long-term commitments to our CHINAMFG customers. Hope to be your partner. |

FAQ:

Q1: Are you a trading company or a manufacturer?

A: We have our own factory.

Q2: Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, 15-30 working days if we don’t. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What are your After-sales services?

A: Before shipment, Each individual product will be strictly inspected on our factory QC Process

System. In addition, We have a

Customer Service team to respond to customers’ questions within 12 hours. Being helpful in

solving customers’ problems is always our goal. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lift cylinders be used in hydraulic vehicle lifts?

Yes, lift cylinders are commonly used in hydraulic vehicle lifts. Here’s an explanation of their utilization in hydraulic vehicle lifts:

Hydraulic vehicle lifts are devices used to raise vehicles for maintenance, repairs, or storage purposes. Lift cylinders play a crucial role in the lifting operation of these hydraulic lifts.

In hydraulic vehicle lifts, lift cylinders are typically positioned vertically and connected to the lifting platform or arms. The lift cylinders work by converting hydraulic pressure into mechanical force, allowing the platform or arms to lift the vehicle. When the hydraulic system is activated, the hydraulic fluid is pressurized, and it flows into the lift cylinders. The force exerted by the pressurized fluid causes the lift cylinders to extend, resulting in the upward movement of the lifting platform or arms.

Lift cylinders used in hydraulic vehicle lifts are usually hydraulic cylinders. Hydraulic systems offer the advantages of smooth operation, precise control, and high lifting capacities. The hydraulic system includes a pump, control valves, hydraulic lines, and the lift cylinders. By controlling the flow of hydraulic fluid to the lift cylinders, operators can easily adjust the lifting height and position of the vehicle.

One of the key benefits of using lift cylinders in hydraulic vehicle lifts is their ability to provide stable and controlled lifting. The lift cylinders are designed to handle the weight of vehicles and ensure safe and secure lifting. They offer reliable support and stability throughout the lifting process, allowing technicians to work on vehicles with confidence.

In addition to lifting capabilities, lift cylinders in hydraulic vehicle lifts may incorporate safety features such as locking mechanisms or overload protection. These safety measures enhance the overall performance and reliability of the lifts, ensuring the safety of both the vehicle and the operators.

Overall, lift cylinders are integral components in hydraulic vehicle lifts, enabling the vertical lifting motion and providing stability during vehicle maintenance and repair operations. Their hydraulic operation, strength, and safety features make them essential for efficient and safe vehicle lifting.

Can Lift Cylinders Be Used in Lifting and Lowering Platforms for Accessibility?

Yes, lift cylinders can be used in lifting and lowering platforms to provide accessibility for individuals with mobility challenges. These cylinders play a crucial role in the operation of accessibility platforms, such as wheelchair lifts, vertical platform lifts, or scissor lifts. Here’s a detailed explanation of how lift cylinders can be used in lifting and lowering platforms for accessibility:

- Lifting Mechanism:

- Smooth and Controlled Movement:

- Weight Capacity:

- Space Optimization:

- Reliability and Durability:

- Integration with Safety Features:

Lift cylinders serve as the primary lifting mechanism in accessibility platforms. These platforms are designed to raise or lower individuals, including wheelchair users, to different heights, allowing them to access elevated areas or overcome vertical barriers. Lift cylinders are typically integrated into the platform structure and connected to a hydraulic or pneumatic system. When activated, the cylinders extend or retract, lifting or lowering the platform in a controlled manner.

Lift cylinders ensure smooth and controlled movement of the accessibility platform during the lifting and lowering process. The cylinders are designed to provide precise and gradual motion, allowing for safe and comfortable vertical transportation. They can be equipped with features such as flow control valves or adjustable dampening to regulate the speed and prevent abrupt movements. Lift cylinders enable individuals to transition between different levels smoothly and securely.

Accessibility platforms need to support the weight of individuals using them, including wheelchair users and their mobility devices. Lift cylinders are manufactured with varying weight capacities to accommodate different load requirements. The cylinders are designed to withstand the vertical forces exerted on the platform and ensure stability and safety during operation. Lift cylinder specifications, such as bore size, rod diameter, and material strength, are carefully selected to match the intended weight capacity of the accessibility platform.

Lift cylinders contribute to space optimization in accessibility platforms. These cylinders are compact and can be integrated within the platform structure, minimizing the need for additional space or external lifting mechanisms. The compact design of lift cylinders allows for efficient utilization of the available platform area, ensuring that the platform can be installed in various settings, including tight spaces or existing structures where space is limited.

Lift cylinders are engineered for reliability and durability to meet the demanding requirements of accessibility platforms. They are designed to withstand frequent usage, heavy loads, and harsh operating conditions. Lift cylinders undergo rigorous testing and quality control measures to ensure their performance and longevity. Manufacturers often provide warranties and maintenance guidelines to support the long-term reliability and safety of lift cylinders used in lifting and lowering platforms.

Accessibility platforms incorporate various safety features to protect users during vertical transportation. Lift cylinders can be integrated with these safety features to enhance the overall system. For example, pressure relief valves can be installed in the hydraulic system to prevent excessive force in case of a malfunction or overload. Additionally, safety sensors, emergency stop buttons, and interlocks can be connected to the lift cylinder system to provide additional layers of safety and control.

Lift cylinders are essential components in lifting and lowering platforms for accessibility. Their role in providing the lifting mechanism, ensuring smooth and controlled movement, accommodating weight capacity, optimizing space, and contributing to reliability and safety makes them a valuable choice for creating inclusive environments and improving accessibility for individuals with mobility challenges.

How does a lift cylinder handle variations in lift height?

A lift cylinder is designed to handle variations in lift height by utilizing its extendable and retractable piston rod. Here’s an explanation of how a lift cylinder handles variations in lift height:

When a lift cylinder is activated, hydraulic fluid is directed into the cylinder chamber, creating pressure that extends the piston rod. As the piston rod extends, it pushes against the load, lifting it to the desired height.

When there are variations in lift height, the lift cylinder adjusts accordingly by controlling the extension and retraction of the piston rod. Here’s how it works:

1. Extending the Piston Rod:

When the lift height needs to increase, the lift cylinder extends the piston rod further. This extension is achieved by increasing the flow of hydraulic fluid into the cylinder chamber. The increased fluid pressure pushes the piston and rod assembly, extending the rod and lifting the load to the required height.

2. Retracting the Piston Rod:

Conversely, when the lift height needs to decrease, the lift cylinder retracts the piston rod. This retraction is achieved by reducing the flow of hydraulic fluid into the cylinder chamber. The decreased fluid pressure allows the piston and rod assembly to retract, lowering the load to the desired height.

3. Precise Control and Positioning:

Lift cylinders are equipped with valves and control mechanisms that allow for precise control and positioning of the piston rod. By regulating the flow of hydraulic fluid and adjusting the pressure, the lift cylinder can achieve accurate and controlled movements, enabling it to handle variations in lift height with precision.

4. Adjustable Stroke Length:

Some lift cylinders have an adjustable stroke length, which refers to the distance the piston rod can travel within the cylinder barrel. By customizing the stroke length, the lift cylinder can accommodate different variations in lift height. The stroke length can be modified by adjusting the cylinder’s dimensions or incorporating additional components.

5. Integration with Control Systems:

Advanced lift cylinder systems can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs), to automate and optimize lift height adjustments. These control systems can monitor and adjust the lift cylinder’s movements based on predetermined parameters or feedback from sensors, ensuring precise and consistent lift height control.

In summary, a lift cylinder handles variations in lift height by extending or retracting the piston rod, controlling the flow and pressure of hydraulic fluid, achieving precise control and positioning, utilizing adjustable stroke length, and integrating with control systems. These capabilities enable the lift cylinder to adapt to different lift height requirements and provide accurate and controlled lifting operations.

editor by Dream 2024-05-17

China Standard Wholesale Price Long Stroke Single Acting Telescopic Agricultural Round Baler Four Post Car Lift Customized Hydraulic Cylinder Manufacturer in China vacuum pump belt

Product Description

Solutions Provider of Hydraulic Cylinder

Product Description

As the professional manufacturer of hydraulic cylinder in China, we can offer you custom products to fulfill every requirement for the hydraulic cylinder market.

-Customized Sizes

-Customized Colors

-Customized Designs

-Customized Packages

-More Requirements Available

The objectives of our business are to provide high quality products and services at a cost effective price.

|

Seal |

Parker, Merkel, NOK, Hallite,etc. |

Helps Links

To get a free sample, please click here |

|

Paint |

Red, Grey, Yellow, Black, etc. |

|

|

Material |

ST52, CK45, 4140, Duplex2205, |

|

|

Certificate |

ABS, Lloyds, SGS, etc. |

|

|

Core components |

Bearing, Pressure vessel, Pump |

|

|

Non-standard |

Yes |

|

|

Structure |

Piston Type, Plunger Type, Telescopic Type |

|

|

Power |

Hydraulic & Pneumatic |

|

|

Brand |

Guoyue |

|

|

Sample |

Available |

Contact the experts at Guoyue today for all your cylinder requirements.

Our Advantages

We have many advantages that will help a lot to your business, including but not limited to:

1. Equipped with State-of-the-art Production Lines

Guoyue has introduced and absorbed advanced hydraulic design and production technologies from European (such as German) and American countries, ensuring that its design and manufacturing capabilities are consistently aligned with international advanced hydraulic cylinder technology.

2. Strict QC Process Before Shipping

The company emphasizes strict quality control, with each production process following standardized operating procedures, and comprehensive management systems in place to ensure that every product is processed to perfection.

3. Success in Many Projects

We have served clients with a diverse range of cylinder requirements, including construction projects, waste management, food industry, mining, infrastructure repairs, metal production, marine, agriculture, oil & gas and more applications.

4. Professional Support in Design, Samples and Bulk Order

As we have our own factories, the more benefits you can get from us:

—–We can get the production done based on the designs, reference pictures, even your drafts.

—–There is no limit of minimum order quantity, and we never refuse the small order, even 1 unit.

—–We can offer you the free samples to check if you buy it in large quantites.

Successful Projects

As the leader in custom hydraulic cylinder design and manufacturing, we have been successful in lot of projects, including

- Aerospace industry: Particularly for such devices as landing gears and CHINAMFG flaps

- Aerial Work Platforms (AWP)

- Agricultural: Small spraying equipment as well as harvesters, loaders and tractors

- Automotive

- Civil Engineering: Bulldozers, excavators, trenchers as well as attachments

- Construction: Concrete pumps and paving applications

- Energy: Flow controls for water gates

- Food, production and manufacturing

- Forestry and logging

- Motorway repairs and maintenance

- Mining

- Materials handling: Single acting hydraulic cylinders for sale are commonly employed in such equipment

- Mechanical engineering: Operation for feeding devices as well as automated production lines, plastic forming machines and transportation devices

- Oil and gas industries

- Recycling plants: Compressing scrap metal and other materials

- Shipbuilding: Steering devices

Company Profile

Guoyue Hydraulic Equipment Manufacturing (ZheJiang ) Co., Ltd., is a high-technology enterprise that integrates research, design, development, production, operation, and service, specializing in the production of hydraulic cylinders, including single acting cylinders, double acting Cylinders, nested cylinders, rotating cylinder, low height cylinders, high tonnage cylinders, tie-rod cylinders and more.

With a registered capital of 50 million Chinese Yuan, the company covers an area of 10, 000 sqft, with more than 100 employees. Also, certified with ISO 9001/ISO 14001/ISO 45001 and many own patents, our products have been approved by clients all over the world, including USA, Europe, Middle East, Middle Asia, Southeast Asia and more countries & areas.

As the leader in custom hydraulic cylinder design and manufacturing, Guoyue serves Original Equipment Manufacturers (OEMs) with custom and innovative hydraulic cylinder solutions. The team at Guoyue liaises closely with each customer to engineer and produce cylinders for machinery, equipment or projects that incorporate cylinders into their hydraulic systems.

We work directly with engineers, business owners, procurement teams, project managers, and technical specialists who often require a custom approach to their cylinder specifications – in terms of fit, function, and overall performance.

Also, Guoyue has introduced and absorbed advanced hydraulic product design and production technologies from Germany and other European and American countries, ensuring that its design and manufacturing capabilities are consistently aligned with international advanced hydraulic cylinder technology.

We have served clients with a diverse range of cylinder requirements. We have extensive experience working within many industries and the unique needs of each – including construction projects, waste management, food Industry, mining, infrastructure repairs, metal production, marine, agriculture, oil & gas and more applications.

Guoyue employees are at the heart of our operations. It is through the dedication of our team at Guoyue that we can consistently deliver the exact services and products required by every client.

Contact the experts at Guoyue today for all your cylinder requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Manufacturer: | Yes |

| Sample: | Available |

| Design Support: | Available |

| Non-Standard: | Yes, Usually Customized |

| Painting Options: | Customized |

| Customization: |

Available

|

|

|---|

How does a lift cylinder contribute to smooth and controlled lifting motion?

A lift cylinder plays a crucial role in ensuring smooth and controlled lifting motion in various applications. Here’s an explanation of how a lift cylinder contributes to this:

1. Hydraulic Operation:

A lift cylinder typically operates using hydraulic power. Hydraulic systems utilize pressurized fluid to generate force and motion. The lift cylinder is connected to the hydraulic system, and when the hydraulic fluid is pressurized, it exerts force on the piston inside the cylinder. This force causes the cylinder to extend or retract, enabling the lifting motion. The hydraulic operation of the lift cylinder provides a smooth and consistent force, resulting in a controlled and precise lifting motion.

2. Synchronization:

In some applications, multiple lift cylinders are used together to achieve synchronized lifting. These cylinders work in tandem, ensuring that the lifting force is evenly distributed and that the load remains level throughout the lifting process. The synchronization of lift cylinders contributes to a smooth and balanced lifting motion, reducing the risk of tilting or instability.

3. Control Valves:

Lift cylinders are often equipped with control valves that allow operators to control the flow and pressure of the hydraulic fluid. By adjusting these control valves, operators can regulate the speed and force of the lifting motion. This provides precise control over the lifting process, allowing for smooth and controlled movements tailored to the specific requirements of the application.

4. Damping and Cushioning:

Some lift cylinders incorporate damping and cushioning mechanisms to further enhance the smoothness and control of the lifting motion. These mechanisms help absorb shocks and vibrations, preventing sudden jolts or jerky movements during the lifting process. Damping and cushioning features contribute to a more comfortable and controlled lifting experience, particularly when dealing with delicate or sensitive loads.

5. Load Capacities:

Lift cylinders are designed to handle specific load capacities based on their size, construction, and specifications. By selecting the appropriate lift cylinder for the intended load, operators can ensure that the lifting motion remains smooth and controlled. Overloading or underloading the lift cylinder can lead to instability or uneven lifting, affecting the overall smoothness and control of the motion.

In summary, a lift cylinder contributes to smooth and controlled lifting motion through its hydraulic operation, synchronization (if applicable), the use of control valves, damping and cushioning mechanisms, and appropriate load capacities. These factors work together to provide reliable and precise lifting, enhancing safety and efficiency in various applications.

Can Lift Cylinders Be Used in Lifting and Lowering Platforms for Accessibility?

Yes, lift cylinders can be used in lifting and lowering platforms to provide accessibility for individuals with mobility challenges. These cylinders play a crucial role in the operation of accessibility platforms, such as wheelchair lifts, vertical platform lifts, or scissor lifts. Here’s a detailed explanation of how lift cylinders can be used in lifting and lowering platforms for accessibility:

- Lifting Mechanism:

- Smooth and Controlled Movement:

- Weight Capacity:

- Space Optimization:

- Reliability and Durability:

- Integration with Safety Features:

Lift cylinders serve as the primary lifting mechanism in accessibility platforms. These platforms are designed to raise or lower individuals, including wheelchair users, to different heights, allowing them to access elevated areas or overcome vertical barriers. Lift cylinders are typically integrated into the platform structure and connected to a hydraulic or pneumatic system. When activated, the cylinders extend or retract, lifting or lowering the platform in a controlled manner.

Lift cylinders ensure smooth and controlled movement of the accessibility platform during the lifting and lowering process. The cylinders are designed to provide precise and gradual motion, allowing for safe and comfortable vertical transportation. They can be equipped with features such as flow control valves or adjustable dampening to regulate the speed and prevent abrupt movements. Lift cylinders enable individuals to transition between different levels smoothly and securely.

Accessibility platforms need to support the weight of individuals using them, including wheelchair users and their mobility devices. Lift cylinders are manufactured with varying weight capacities to accommodate different load requirements. The cylinders are designed to withstand the vertical forces exerted on the platform and ensure stability and safety during operation. Lift cylinder specifications, such as bore size, rod diameter, and material strength, are carefully selected to match the intended weight capacity of the accessibility platform.

Lift cylinders contribute to space optimization in accessibility platforms. These cylinders are compact and can be integrated within the platform structure, minimizing the need for additional space or external lifting mechanisms. The compact design of lift cylinders allows for efficient utilization of the available platform area, ensuring that the platform can be installed in various settings, including tight spaces or existing structures where space is limited.

Lift cylinders are engineered for reliability and durability to meet the demanding requirements of accessibility platforms. They are designed to withstand frequent usage, heavy loads, and harsh operating conditions. Lift cylinders undergo rigorous testing and quality control measures to ensure their performance and longevity. Manufacturers often provide warranties and maintenance guidelines to support the long-term reliability and safety of lift cylinders used in lifting and lowering platforms.

Accessibility platforms incorporate various safety features to protect users during vertical transportation. Lift cylinders can be integrated with these safety features to enhance the overall system. For example, pressure relief valves can be installed in the hydraulic system to prevent excessive force in case of a malfunction or overload. Additionally, safety sensors, emergency stop buttons, and interlocks can be connected to the lift cylinder system to provide additional layers of safety and control.

Lift cylinders are essential components in lifting and lowering platforms for accessibility. Their role in providing the lifting mechanism, ensuring smooth and controlled movement, accommodating weight capacity, optimizing space, and contributing to reliability and safety makes them a valuable choice for creating inclusive environments and improving accessibility for individuals with mobility challenges.

Can lift cylinders be repaired or replaced when damaged?

Yes, lift cylinders can be repaired or replaced when they are damaged. Here’s an explanation of the options for repairing or replacing lift cylinders:

1. Repair:

If a lift cylinder sustains damage, it is often possible to repair it. The extent of the damage and the specific components affected will determine the repair process. Common repairs may involve replacing seals, gaskets, or damaged hydraulic lines. In some cases, the cylinder may need to be disassembled, cleaned, and reassembled with new parts.

Repairing a lift cylinder typically requires expertise in hydraulic systems and cylinder repair. It is recommended to consult qualified professionals or authorized service centers to ensure proper diagnosis and repair procedures.

2. Replacement of Components:

If specific components within the lift cylinder are damaged or worn out, it may be possible to replace those components individually. This can include replacing the piston, rod, seals, or other internal parts. By replacing only the affected components, the cylinder can be restored to proper working condition without replacing the entire unit.

Replacement of components should be done with compatible parts that meet the manufacturer’s specifications. It may be necessary to consult the manufacturer’s documentation or seek guidance from authorized distributors or service centers to ensure proper component selection and installation.

3. Replacement of the Entire Cylinder:

In cases where the lift cylinder is severely damaged or if repairing or replacing individual components is not practical or cost-effective, it may be necessary to replace the entire cylinder. This involves removing the damaged cylinder and installing a new one that matches the specifications and requirements of the lifting equipment.

When replacing the entire cylinder, it is important to ensure compatibility with the equipment, including load capacity, mounting options, stroke length, and other specifications. The new cylinder should be selected based on the equipment’s requirements and the recommendations of the manufacturer or qualified experts.

4. Professional Assistance:

Repairing or replacing lift cylinders can be complex, especially when dealing with hydraulic systems and precise components. It is recommended to seek professional assistance from qualified technicians or authorized service centers. They have the knowledge, experience, and tools to properly diagnose, repair, or replace lift cylinders, ensuring the safety and optimal performance of the lifting equipment.

In summary, lift cylinders can be repaired or replaced when damaged. Repair options may involve replacing seals or damaged components, while component replacement allows for targeted repairs. In severe cases or when individual repairs are not feasible, the entire cylinder may need to be replaced. Professional assistance is recommended to ensure proper diagnosis, repair procedures, or component selection for the repair or replacement of lift cylinders.

editor by Dream 2024-05-16

China Custom 4 Post Car Lift Hoist Car Lifting 5000kg Car Lift Rise Pads Hydraulic Cylinder Drive vacuum pump adapter

Product Description

Product Description

1.Floor plate style design, more suitable for low ceiling workshop 2. Complete streel welding performance more ad cantage 3.Symmetric arms dabber welding make more stable 4.Adopt quality pack power, more endurable, running safely and reliably 5.Strip design,elegant appearance

|

Model |

MS-4000BM |

MS-5000BM |

|

Lifting weight(t) |

4 |

5 |

|

Overall width(mm) |

3370 |

3420 |

|

Overall height(mm) |

2776 |

2800 |

|

Lifting height(mm) |

1850 |

1800 |

|

Lane width(mm) |

2772 |

2798 |

|

Motor power(kw) |

2.2 |

2.2 |

|

Voltage(v) |

110/220/380 |

110/220/380 |

|

Gross weight(control box weight)kg |

35 |

35 |

|

(Machine weight)kg |

535 |

700 |

|

Packing size(mm) |

2800*530*720 |

2820*450*750 |

|

|

860*260*330 |

850*260*240 |

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

ZheJiang Maysun Machinery Co., Ltd. is located in HangZhou City, ZheJiang Province. It is a technology-based enterprise integrating research and development, sales and service of branch crusher, copper wire granulator, pile driver and hydraulic scissor lift. Over the years, Maysun Machinery has been committed to the field of new energy, has solved the integration of the supply quantity of pile driver for solar energy, electric pile driver, self-propelled hydraulic scissor lift, etc., to provide customers at home and abroad with the best quality products and professional services, the products have been sold to Europe, America, Southeast Asia and Africa and other more than 50 countries and regions of the, won a good reputation.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to Domestic Market(45.00%),Southeast Asia(20.00%),Africa(15.00%),South America(10.00%),Eastern Europe(10.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Dust Removal Equipment, Hydraulic Scissor Lift, Copper Wire Granulator, Pile Breaking Machine, Power Trowel

4. why should you buy from us not from other suppliers?

To provide customers at home and abroad with the best quality products and professional services, the products have been sold to Europe, America, Southeast Asia and Africa and other more than 50 countries and regions of the, won a good reputation.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C;

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Four Cylinder Hydraulic Lift |

| Samples: |

US$ 1720/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a lift cylinder contribute to efficient and reliable lifting?

A lift cylinder plays a crucial role in enabling efficient and reliable lifting operations. Here’s an explanation of how a lift cylinder contributes to efficient and reliable lifting:

1. High Lifting Capacity:

Lift cylinders are specifically designed to provide high lifting capacities. They can generate substantial force to lift heavy loads, making them well-suited for material handling tasks that involve large or bulky items. The high lifting capacity ensures that the cylinder can effectively handle the intended load, contributing to efficient lifting without the need for additional equipment or manual labor.

2. Precise Control:

Lift cylinders offer precise control over the lifting process. By regulating the flow and pressure of hydraulic fluid, operators can achieve accurate positioning and controlled movements. This level of control allows for efficient and precise placement of the load, reducing the risk of damage to the load or surrounding objects. The precise control also enables operators to optimize the lifting process, saving time and effort.

3. Smooth and Stable Operation:

Lift cylinders provide smooth and stable operation during lifting operations. The hydraulic system ensures that the lifting motion is steady and controlled, minimizing jerking or sudden movements. This smooth operation is important for the safe handling of delicate or fragile materials. It also enhances operator confidence and reduces the risk of accidents, contributing to reliable lifting performance.

4. Quick Response Time:

Lift cylinders offer quick response times, allowing for efficient and timely lifting operations. When activated, the hydraulic system quickly directs fluid into the cylinder, initiating the lifting motion. This rapid response time reduces downtime and enables operators to complete lifting tasks more efficiently.

5. Durability and Reliability:

Lift cylinders are built to withstand the demands of heavy-duty lifting operations. They are constructed with durable materials and designed to handle repetitive lifting tasks over extended periods. The robust construction and reliable performance of lift cylinders ensure that they can consistently deliver efficient lifting performance without frequent breakdowns or malfunctions.

6. Safety Features:

Lift cylinders often incorporate safety features to enhance reliability during lifting operations. These features can include load-holding valves, pressure relief valves, and fail-safe mechanisms. Load-holding valves prevent the load from dropping in the event of hydraulic pressure loss, ensuring the load remains securely lifted. Pressure relief valves protect the system from excessive pressure, preventing potential damage. Fail-safe mechanisms provide additional safety by engaging in the event of a system failure or power loss. The presence of these safety features contributes to reliable and safe lifting operations.

7. Integration with Control Systems:

Advanced lift cylinders can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs). This integration allows for automation and optimized control of the lifting process. By incorporating sensors, feedback mechanisms, and pre-programmed sequences, the lift cylinder can operate efficiently and reliably with minimal operator intervention.

In summary, a lift cylinder contributes to efficient and reliable lifting through its high lifting capacity, precise control, smooth and stable operation, quick response time, durability and reliability, incorporation of safety features, and integration with control systems. These features and capabilities ensure that the lifting process is efficient, accurate, and safe, thereby enhancing overall lifting performance.

How does a lift cylinder handle variations in cylinder stroke length?

A lift cylinder is designed to handle variations in cylinder stroke length through its adjustable rod or piston. The stroke length refers to the distance the cylinder can extend or retract, and it can be adjusted to meet specific requirements in different applications.

In hydraulic lift cylinders, the stroke length can be modified by adjusting the position of the rod or piston within the cylinder. This adjustment is typically achieved by adding or removing spacers or by using adjustable stops. By changing the effective length of the cylinder, the stroke can be increased or decreased accordingly.

The adjustment of the stroke length allows the lift cylinder to accommodate different operational needs. For example, in material handling applications, where varying load sizes are encountered, the stroke length can be adjusted to ensure that the cylinder extends or retracts precisely to the required position. This flexibility enables the lift cylinder to handle a wide range of loads and adapt to different lifting or pushing scenarios.

In addition to adjusting the stroke length, lift cylinders often incorporate position feedback mechanisms. These mechanisms, such as linear transducers or position sensors, provide real-time feedback on the actual position of the cylinder. By monitoring the position, the control system can ensure accurate and precise control over the cylinder’s movement, regardless of the stroke length.

The ability to handle variations in cylinder stroke length is crucial in many industrial applications. It allows for adaptability, efficiency, and improved performance in tasks such as material handling, assembly, and automation. By adjusting the stroke length, lift cylinders can optimize their operation, ensuring that the required force and movement are achieved consistently.

In summary, lift cylinders handle variations in cylinder stroke length through adjustable rods or pistons. This adjustment capability, combined with position feedback mechanisms, enables precise control and adaptability in different applications. By accommodating different stroke lengths, lift cylinders can effectively meet the specific requirements of a wide range of industrial tasks.

Can lift cylinders be customized for specific lifting equipment?

Yes, lift cylinders can be customized for specific lifting equipment to meet the unique requirements of different applications. Here’s an explanation of how lift cylinders can be customized:

Lift cylinders are designed to be versatile and adaptable, making them suitable for a wide range of lifting applications. However, certain lifting equipment may have specific needs or constraints that require customization of the lift cylinders. Here are some ways lift cylinders can be customized:

1. Load Capacity:

Lift cylinders can be customized to accommodate different load capacities. The size and specifications of the cylinder, such as the diameter of the piston and the pressure rating, can be adjusted to match the lifting equipment’s specific load requirements. This ensures that the lift cylinder can handle the intended load safely and efficiently.

2. Mounting Options:

The mounting configuration of a lift cylinder can be customized to suit the specific lifting equipment. Different types of mounting options, such as flange mounts, clevis mounts, or trunnion mounts, can be designed and integrated into the cylinder to ensure proper attachment and alignment with the equipment.

3. Stroke Length:

The stroke length of a lift cylinder can be customized to meet the lifting equipment’s vertical travel requirements. By adjusting the length of the piston rod or modifying the cylinder’s dimensions, the stroke length can be tailored to achieve the desired lifting range for the equipment.

4. Operating Speed:

In some cases, the operating speed of the lift cylinder may need to be customized. The hydraulic system parameters, such as the flow rate and valve settings, can be adjusted to control the extension and retraction speed of the cylinder. This customization ensures that the lifting equipment operates at the desired speed for efficient and precise lifting.

5. Environmental Considerations:

For lifting equipment used in specific environments, such as extreme temperatures, corrosive atmospheres, or hazardous conditions, lift cylinders can be customized to withstand these conditions. Special materials, coatings, or seals can be employed to enhance the cylinder’s durability and resistance to environmental factors.

6. Integration with Control Systems:

Customized lift cylinders can be integrated with control systems and automation technologies specific to the lifting equipment. This integration enables precise control, synchronized movements, and seamless integration with other equipment or processes, optimizing the overall performance and efficiency of the lifting system.

In summary, lift cylinders can be customized for specific lifting equipment by adjusting load capacity, mounting options, stroke length, operating speed, considering environmental factors, and integrating with control systems. Customization ensures that the lift cylinders are tailored to meet the unique requirements of the lifting equipment, enabling safe, efficient, and reliable lifting operations.

editor by CX 2024-04-03

China wholesaler Hydraulic Cylinder for Four 4 Post Lift with Good quality

Product Description

Specifications:

| Product Name | HSG Series Hydraulic Cylinder |

| Work Press | 7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

| Material | Aluminum, Cast Iron,45mnb Steel, Stainless Steel |

| Bore Size | 40mm–320mm, Customizable |

| Shaft Diameter | 20mm–220mm, Customizable |

| Stroke Length | 30mm–14100mm, Customizable |

| Rod Surface Hardness | HRC48-54 |

| Operating Temperature | -40°C to +120 °C |

| Paint Color | Black, Yellow, Blue, Brown, Customizable |

| Service | OEM&ODM |

| Warranty | 1 Year |

| MOQ | 1 Piece |

| Delivery Time | 7-15 Days, Also depending on specific demands |

| Certification | ISO9001,CE |

| Capacity | 50,000Pcs per year |

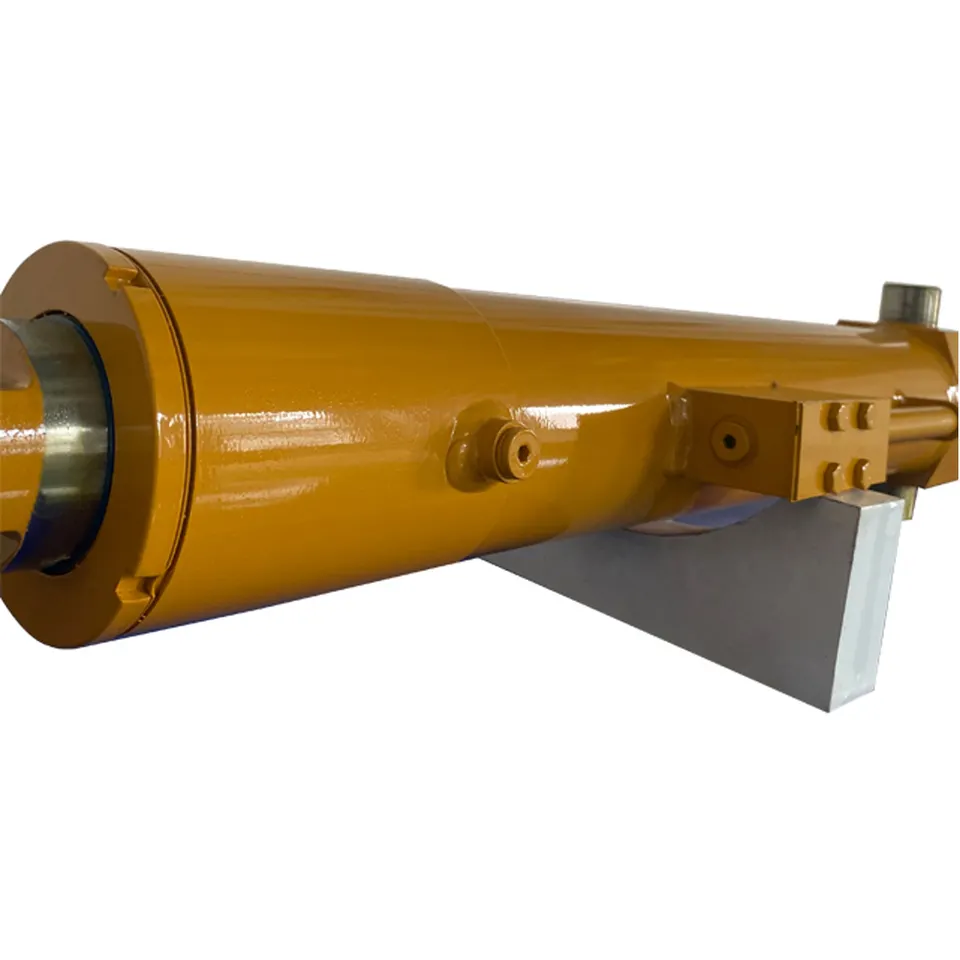

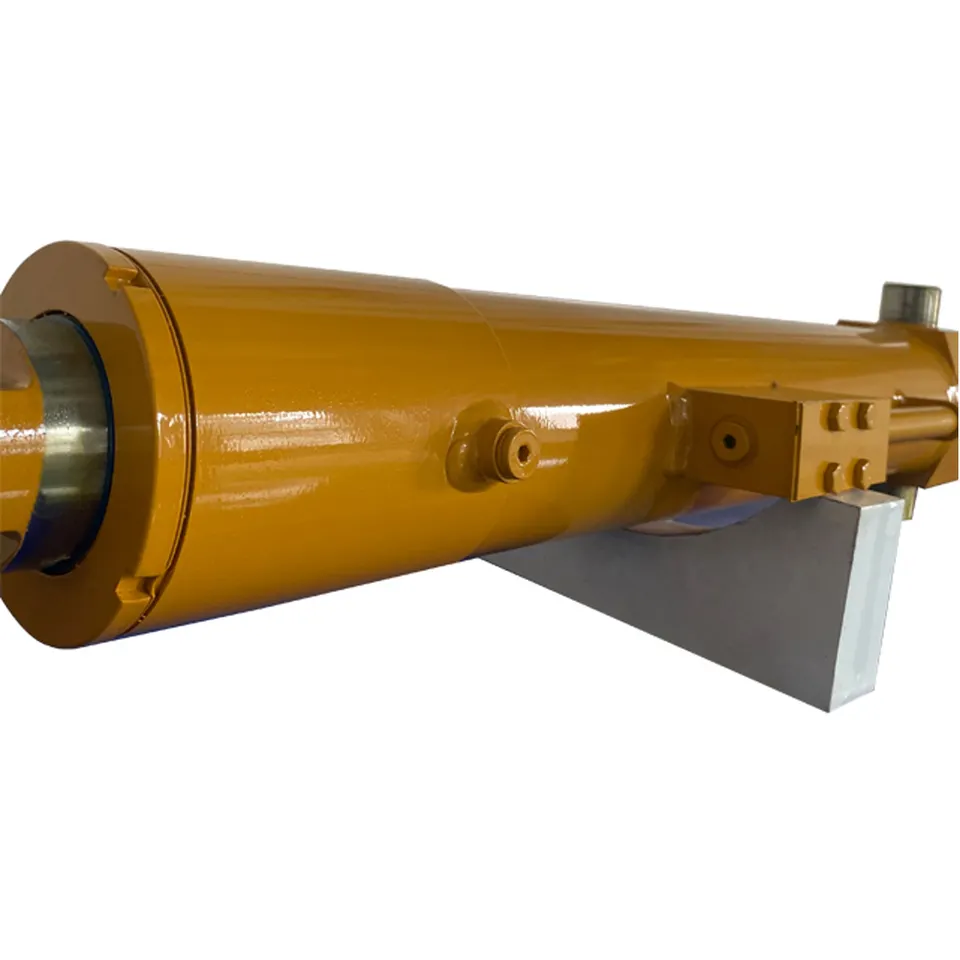

Product Display:

Mounting:

Working Flow: About Us

Tongte designs and manufactures durable, heavy-duty hydraulic products and accessories and offers lifecycle services to them. We constantly develop our machine base and operations to meet customer-specific needs and remain leaders in the industry. Beyond all else, we want to be the trusted, groundbreaking partner our customers truly need.

In addition to the customized cylinders, CHINAMFG offers hydraulic power units, Electric-Hydraulic linear actuators, piston accumulators, system configurations, and versatile services such as repair and manufacturing services. The modern production facilities are located in HangZhou, ZheJiang (China) where production started in 2001. The core values of Tongke guiding its business strongly are commitment, sustainability, interaction, and customer-first.

We possess over 20 years of experience in the industry and extensive global market experience, our customers are located all over the world, and we truly commit to the customers’ needs – these are the success factors of our family-owned company. Our vision is to grow and expand the business further into global markets.

FAQ:

Q1: What does your company do?

A: we are a supplier of high-quality hydraulic products including Hydraulic Cylinders, Hydraulic Power packs, Hydraulic Linear, and other Hydraulic components.

Q2:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q3:Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, and 15-30 working days if we don’t. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What is your warranty policy?

A: All our products are warranted for 1 full year from the date of delivery against defects in materials and workmanship. Each individual product will be strictly inspected on our factory QC Process

System before shipment. We also have a Customer Service team to respond to customers’ questions within 12 hours. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

Can lift cylinders be used in aerial work platforms and scissor lifts?

Yes, lift cylinders are commonly used in aerial work platforms and scissor lifts. Here’s an explanation of their utilization in these types of equipment:

Aerial work platforms, also known as aerial lifts or elevated work platforms, are used to provide elevated access for various tasks, such as maintenance, construction, or inspection work. Scissor lifts are a specific type of aerial work platform that utilize a scissor mechanism to vertically extend the platform. Lift cylinders play a crucial role in the lifting operation of both aerial work platforms and scissor lifts.

In scissor lifts, multiple lift cylinders are typically positioned vertically and connected to the scissor mechanism. These lift cylinders work in synchronization to extend or retract the scissor arms, thereby raising or lowering the platform. The lift cylinders exert force to expand the scissor arms, creating a lifting motion that allows the platform to reach elevated positions. By controlling the flow of hydraulic fluid to the lift cylinders, operators can easily adjust the platform height and achieve the desired working elevation.

Lift cylinders used in aerial work platforms and scissor lifts are usually hydraulic cylinders. Hydraulic systems offer the advantages of smooth operation, precise control, and high lifting capacities. The hydraulic system includes a pump, control valves, hydraulic lines, and the lift cylinders. When the hydraulic system is activated, the pump pressurizes the hydraulic fluid, which is then directed to the lift cylinders through the control valves. The pressurized fluid causes the lift cylinders to extend, resulting in the upward movement of the platform.

One of the key benefits of using lift cylinders in aerial work platforms and scissor lifts is their ability to provide stable and controlled lifting. The synchronized movement of the lift cylinders ensures that the platform remains level and secure during the lifting process. This stability is essential for safe working conditions at elevated heights.

In addition to lifting capabilities, lift cylinders in aerial work platforms and scissor lifts may incorporate features such as safety locks, overload protection, or emergency descent mechanisms. These safety measures enhance the overall performance and reliability of the equipment, ensuring the well-being of operators working at height.

Overall, lift cylinders are integral components in aerial work platforms and scissor lifts, enabling the vertical lifting motion and providing stability during elevated work. Their hydraulic operation, synchronized movement, and safety features make them essential for efficient and secure access at height.

Can lift cylinders be used in agricultural machinery and equipment?

Yes, lift cylinders are commonly used in agricultural machinery and equipment. Here’s an explanation of their utilization in this context:

Agricultural machinery and equipment often require lifting capabilities to perform various tasks such as loading, lifting, and adjusting components. Lift cylinders provide the necessary force and control to accomplish these operations effectively.

1. Tractors and Loaders:

Lift cylinders are extensively used in agricultural tractors and loaders. These cylinders are typically integrated into the hydraulic systems of the equipment and are responsible for lifting and lowering front-end attachments, such as buckets, forks, or blades. By extending and retracting the lift cylinders, operators can control the height and position of the attachments, enabling efficient material handling, loading, and leveling tasks.

2. Harvesting and Threshing Equipment:

In harvesting and threshing equipment, lift cylinders are employed to adjust and control the height of components such as headers, cutter bars, or platforms. These cylinders enable operators to adapt to different crop heights and ground conditions, ensuring optimal harvesting performance. By utilizing lift cylinders, agricultural machinery can effectively navigate uneven terrain and maintain consistent cutting or harvesting heights.

3. Sprayers and Spreaders:

Lift cylinders are also utilized in agricultural sprayers and spreaders. These cylinders are responsible for raising and lowering the booms or spreading mechanisms. By adjusting the lift cylinders, operators can control the application height or spreading width, ensuring precise and uniform coverage of fertilizers, pesticides, or seeds.

4. Irrigation Systems:

In irrigation systems, lift cylinders are used to control the height and position of irrigation equipment such as sprinklers or pivots. These cylinders allow for efficient adjustment of the irrigation components to ensure optimal water distribution across agricultural fields.

5. Implements and Attachments:

Lift cylinders are widely employed in various agricultural implements and attachments, including plows, harrows, cultivators, and seed drills. These cylinders facilitate the lifting and lowering of the implements, allowing for depth adjustments, ground clearance, and transport modes. Lift cylinders enhance the versatility and functionality of agricultural equipment, enabling farmers to efficiently perform a wide range of field operations.

In summary, lift cylinders have significant applications in agricultural machinery and equipment. They contribute to the lifting, lowering, and positioning tasks required for efficient material handling, leveling, harvesting, spreading, and irrigation operations. By utilizing lift cylinders, agricultural equipment becomes more versatile, productive, and adaptable to the specific needs of farmers and agricultural practices.

Can you explain the role of hydraulic fluid in a lift cylinder?

Hydraulic fluid plays a crucial role in the operation of a lift cylinder. It serves as the medium through which force is transmitted to generate motion and provide lifting or lowering capabilities. Here’s an explanation of the role of hydraulic fluid in a lift cylinder:

1. Transmission of Force:

Hydraulic fluid acts as a medium for transmitting force within the lift cylinder. When pressurized, the hydraulic fluid applies force on the piston, which then transfers that force to the load through the rod. The force exerted by the hydraulic fluid is transmitted equally in all directions due to Pascal’s law, allowing for effective lifting or lowering of heavy loads.

2. Energy Transfer:

Hydraulic fluid is responsible for transferring energy within the hydraulic system. The hydraulic fluid is pressurized by a pump, which converts mechanical energy into hydraulic energy. This pressurized fluid carries the energy to the lift cylinder, where it is converted back into mechanical energy to perform the lifting or lowering action. The ability of hydraulic fluid to store and transmit energy efficiently makes it ideal for power transmission in hydraulic systems.

3. Lubrication and Cooling:

Hydraulic fluid serves as a lubricant within the lift cylinder to reduce friction and wear between moving parts, such as the piston and the cylinder barrel. This lubrication helps to enhance the longevity and smooth operation of the cylinder components. Additionally, the hydraulic fluid also aids in cooling the system by absorbing heat generated during operation, preventing overheating and ensuring optimal performance.

4. Sealing and Contamination Control:

Hydraulic fluid plays a critical role in sealing the lift cylinder and preventing leakage. It works in conjunction with seals located between the piston and cylinder barrel, as well as around the rod, to create a tight and secure hydraulic system. The hydraulic fluid also helps to control contamination by keeping external contaminants, such as dirt and debris, from entering the cylinder and affecting its performance.

5. System Efficiency:

The properties of hydraulic fluid, such as its viscosity and flow characteristics, directly impact the efficiency of the lift cylinder system. The choice of the appropriate hydraulic fluid ensures smooth and efficient operation, minimizing energy losses and maximizing system performance.

In summary, hydraulic fluid plays a vital role in a lift cylinder by transmitting force, transferring energy, lubricating and cooling the system, sealing against leaks, controlling contamination, and contributing to system efficiency. It enables the lift cylinder to generate the necessary force and motion to lift or lower heavy loads, while also ensuring the smooth and reliable operation of the hydraulic system.

editor by CX 2023-12-27

China Standard Hydraulic Cylinder for 2 Post Lifter Car Lift Replacement with Good quality

Product Description

Specifications:

| Product Name | HSG Series Hydraulic Cylinder |

| Work Press | 7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

| Material | Aluminum, Cast Iron,45mnb Steel, Stainless Steel |

| Bore Size | 40mm–320mm, Customizable |

| Shaft Diameter | 20mm–220mm, Customizable |

| Stroke Length | 30mm–14100mm, Customizable |

| Rod Surface Hardness | HRC48-54 |

| Operating Temperature | -40°C to +120 °C |

| Paint Color | Black, Yellow, Blue, Brown, Customizable |

| Service | OEM&ODM |

| Warranty | 1 Year |

| MOQ | 1 Piece |

| Delivery Time | 7-15 Days, Also depending on specific demands |

| Certification | ISO9001,CE |

| Capacity | 50,000Pcs per year |

Product Display:

Mounting:

Working Flow: About Us

Tongte designs and manufactures durable, heavy-duty hydraulic products and accessories and offers lifecycle services to them. We constantly develop our machine base and operations to meet customer-specific needs and remain leaders in the industry. Beyond all else, we want to be the trusted, groundbreaking partner our customers truly need.

In addition to the customized cylinders, CHINAMFG offers hydraulic power units, Electric-Hydraulic linear actuators, piston accumulators, system configurations, and versatile services such as repair and manufacturing services. The modern production facilities are located in HangZhou, ZheJiang (China) where production started in 2001. The core values of Tongke guiding its business strongly are commitment, sustainability, interaction, and customer-first.

We possess over 20 years of experience in the industry and extensive global market experience, our customers are located all over the world, and we truly commit to the customers’ needs – these are the success factors of our family-owned company. Our vision is to grow and expand the business further into global markets.

FAQ:

Q1: What does your company do?

A: we are a supplier of high-quality hydraulic products including Hydraulic Cylinders, Hydraulic Power packs, Hydraulic Linear, and other Hydraulic components.

Q2:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q3:Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, and 15-30 working days if we don’t. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What is your warranty policy?

A: All our products are warranted for 1 full year from the date of delivery against defects in materials and workmanship. Each individual product will be strictly inspected on our factory QC Process

System before shipment. We also have a Customer Service team to respond to customers’ questions within 12 hours.

| Certification: | ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lift cylinders be used in dock levelers and loading ramps?

Yes, lift cylinders can be used in dock levelers and loading ramps. Here’s an explanation of their utilization in these applications:

Dock levelers and loading ramps are essential equipment in logistics and transportation facilities, allowing for efficient loading and unloading of goods between trucks and loading docks. Lift cylinders play a crucial role in these systems by providing the necessary lifting and positioning capabilities.

In dock levelers, lift cylinders are employed to bridge the gap between the loading dock and the truck bed, ensuring a smooth transition for material handling equipment such as forklifts or pallet jacks. These cylinders are typically integrated into the mechanical or hydraulic systems of the dock leveler, allowing for controlled vertical movement. By extending or retracting the lift cylinders, the dock leveler can be adjusted to match the height of the truck bed, enabling safe and efficient loading or unloading of cargo.

Loading ramps, also known as mobile yard ramps or portable ramps, are used in situations where a permanent loading dock is not available or when additional flexibility is required. Lift cylinders are utilized in loading ramps to provide the means for height adjustment and inclination control. By extending or retracting the lift cylinders, the ramp can be raised or lowered to align with the truck bed height, facilitating the movement of goods between the ramp and the truck.

The use of lift cylinders in dock levelers and loading ramps ensures precise and controlled positioning during the loading and unloading process. Operators can adjust the lift cylinders to match the specific height requirements, allowing for smooth and safe transfer of materials without causing damage to the goods or the equipment.

Lift cylinders used in dock levelers and loading ramps are designed to withstand heavy loads and endure frequent use. They are constructed with robust materials and incorporate features such as seals and bearings to ensure durability and reliability in demanding industrial environments.

Furthermore, lift cylinders in dock levelers and loading ramps may incorporate safety features such as automatic descent control or velocity fuses. These safety mechanisms help prevent sudden drops or uncontrolled movements in the event of a hydraulic system failure, enhancing the overall safety of the loading and unloading operations.

In summary, lift cylinders are commonly utilized in dock levelers and loading ramps to provide reliable and controlled lifting and positioning capabilities. Their ability to handle heavy loads, facilitate height adjustment, and incorporate safety features makes them integral components in these applications, contributing to efficient and safe material handling operations.

Can lift cylinders be used in manufacturing and production machinery?

Yes, lift cylinders are commonly used in manufacturing and production machinery. Lift cylinders, also known as hydraulic cylinders, are devices that generate linear force and motion through the use of pressurized hydraulic fluid. They are widely employed in various industrial applications for lifting, pushing, pulling, and holding heavy loads.

In manufacturing and production machinery, lift cylinders play a crucial role in providing controlled movement and force for a wide range of tasks. Here are some examples of how lift cylinders are used:

- Material Handling: Lift cylinders are utilized in machinery such as forklifts, cranes, and material handling equipment to lift and transport heavy objects. They allow for precise positioning and movement of loads, improving efficiency and safety in material handling operations.

- Assembly and Automation: Lift cylinders are integrated into assembly lines and automated machinery to perform tasks like part insertion, pressing, and clamping. They provide the necessary force and motion required for assembling components or joining parts together.

- Presses and Punching Machines: Lift cylinders are employed in presses and punching machines to exert force for bending, forming, and shaping materials. These cylinders ensure accurate and consistent results in metalworking processes.

- Industrial Robots: Lift cylinders are used in robotic systems to enable lifting and manipulation of objects. They facilitate the controlled movement of robot arms and end-effectors, allowing robots to perform tasks such as pick-and-place operations, welding, and painting.

Lift cylinders offer several advantages in manufacturing and production machinery. They provide high force capabilities, precise control over movement, compact design, and the ability to operate in various orientations. Furthermore, their hydraulic nature allows for smooth and gradual acceleration and deceleration, reducing the risk of damage to the machinery or the materials being handled.

In conclusion, lift cylinders are extensively utilized in manufacturing and production machinery across different industries. Their versatility, reliability, and ability to generate controlled linear force make them essential components in a wide range of industrial applications.

How does a lift cylinder handle variations in lift height?

A lift cylinder is designed to handle variations in lift height by utilizing its extendable and retractable piston rod. Here’s an explanation of how a lift cylinder handles variations in lift height:

When a lift cylinder is activated, hydraulic fluid is directed into the cylinder chamber, creating pressure that extends the piston rod. As the piston rod extends, it pushes against the load, lifting it to the desired height.

When there are variations in lift height, the lift cylinder adjusts accordingly by controlling the extension and retraction of the piston rod. Here’s how it works:

1. Extending the Piston Rod:

When the lift height needs to increase, the lift cylinder extends the piston rod further. This extension is achieved by increasing the flow of hydraulic fluid into the cylinder chamber. The increased fluid pressure pushes the piston and rod assembly, extending the rod and lifting the load to the required height.

2. Retracting the Piston Rod:

Conversely, when the lift height needs to decrease, the lift cylinder retracts the piston rod. This retraction is achieved by reducing the flow of hydraulic fluid into the cylinder chamber. The decreased fluid pressure allows the piston and rod assembly to retract, lowering the load to the desired height.

3. Precise Control and Positioning:

Lift cylinders are equipped with valves and control mechanisms that allow for precise control and positioning of the piston rod. By regulating the flow of hydraulic fluid and adjusting the pressure, the lift cylinder can achieve accurate and controlled movements, enabling it to handle variations in lift height with precision.

4. Adjustable Stroke Length:

Some lift cylinders have an adjustable stroke length, which refers to the distance the piston rod can travel within the cylinder barrel. By customizing the stroke length, the lift cylinder can accommodate different variations in lift height. The stroke length can be modified by adjusting the cylinder’s dimensions or incorporating additional components.

5. Integration with Control Systems:

Advanced lift cylinder systems can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs), to automate and optimize lift height adjustments. These control systems can monitor and adjust the lift cylinder’s movements based on predetermined parameters or feedback from sensors, ensuring precise and consistent lift height control.

In summary, a lift cylinder handles variations in lift height by extending or retracting the piston rod, controlling the flow and pressure of hydraulic fluid, achieving precise control and positioning, utilizing adjustable stroke length, and integrating with control systems. These capabilities enable the lift cylinder to adapt to different lift height requirements and provide accurate and controlled lifting operations.

editor by CX 2023-12-04

China Custom Portable Concentric Ground Hydro Post Auto Wash Cylinders Scissor Gear Two in Car Pump Lift for Truck Hydraulic Hoist Krm92 vacuum pump and compressor

Product Description

Hoist Mechanism,Dimensions & Mass(appros.)

| L(mm) | W(mm) | H(mm) | X(mm) | MASS(kg) | |

| 1120 | 516 | 400 | 548 | 90 | |

Hoist Cylinder and Pump Combination Specification (approx.)

|

Hoist Cylinder KRM92 |

Working Pressure (MPa) (Kgf/cm2) |

6.4 |

Gear Pump KP-55 |

Standard Revolution (rpm) |

800 |

|

65 |

|||||

|

Inner Diameter (mm) |

160 |

Discharge Volume(ml/rev.) |

55 |

||

|

Stroke (mm) |

405 |

Max. Testing Pressure (MPa) (Kgf/cm2) |

14.7 |

||

|

Min. Close distance (mm) |

666 |

||||

|

150 |

|||||

|

Piston Rod Diameter (mm) |

45 |

Weight(kg) |

13 |

||

|

Max. pressure (MPa) (Kgf/cm2) |

14.7 |

||||

|

150 |

Hoist Mounting and Maximum Lifting Capacity

|

Recommended Truck G.W.(kg) |

Body Length(mm) |

Rear Overhang(mm) |

Distance between Load Center to Hinge(mm) |

Distance between trunion to Hinge(mm) |

Rated Lifting Capacity(kg) |

Designed Max. lifting Capacity(kg) (including load weight) |

|

4000-5500 |

3100 |

340 |

1210 |

1270 |

3000-5000 |

32100/60° |

| Type: | Hoist |

|---|---|

| Structure: | Hydraulic Jack |

| Capacity (Load): | 1-10T |

| Power Source: | Hydraulic |

| Max Height: | >400mm |

| Condition: | New |

| Customization: |

Available

|

|

|---|

Can hydraulic cylinders be integrated with modern telematics and remote monitoring?

Yes, hydraulic cylinders can indeed be integrated with modern telematics and remote monitoring systems. The integration of hydraulic cylinders with telematics and remote monitoring technology offers numerous benefits, including enhanced operational efficiency, improved maintenance practices, and increased overall productivity. Here’s a detailed explanation of how hydraulic cylinders can be integrated with modern telematics and remote monitoring:

1. Sensor Integration:

– Hydraulic cylinders can be equipped with various sensors to gather real-time data about their performance and operating conditions. Sensors such as pressure transducers, temperature sensors, position sensors, and load sensors can be integrated directly into the cylinder or its associated components. These sensors provide valuable information about parameters such as pressure, temperature, position, and load, enabling remote monitoring and analysis of the cylinder’s behavior.

2. Data Transmission:

– The data collected from the sensors in hydraulic cylinders can be transmitted wirelessly or through wired connections to a central monitoring system. Wireless communication technologies such as Bluetooth, Wi-Fi, or cellular networks can be employed to transmit data in real-time. Alternatively, wired connections such as Ethernet or CAN bus can be utilized for data transmission. The choice of communication method depends on the specific requirements of the application and the available infrastructure.

3. Remote Monitoring Systems:

– Remote monitoring systems receive and process the data transmitted from hydraulic cylinders. These systems can be cloud-based or hosted on local servers, depending on the implementation. Remote monitoring systems collect and analyze the data to provide insights into the cylinder’s performance, health, and usage patterns. Operators and maintenance personnel can access the monitoring system through web-based interfaces or dedicated software applications to view real-time data, receive alerts, and generate reports.

4. Condition Monitoring and Predictive Maintenance:

– Integration with telematics and remote monitoring enables condition monitoring and predictive maintenance of hydraulic cylinders. By analyzing the collected data, patterns and trends can be identified, allowing for the detection of potential issues or anomalies before they escalate into major problems. Predictive maintenance algorithms can be applied to the data to generate maintenance schedules, recommend component replacements, and optimize maintenance activities. This proactive approach helps prevent unexpected downtime, reduces maintenance costs, and maximizes the lifespan of hydraulic cylinders.

5. Performance Optimization:

– The data collected from hydraulic cylinders can also be utilized to optimize their performance. By analyzing parameters such as pressure, temperature, and load, operators can identify opportunities for improving operational efficiency. Insights gained from the remote monitoring system can guide adjustments in system settings, load management, or operational practices to optimize the performance of hydraulic cylinders and the overall hydraulic system. This optimization can result in energy savings, improved productivity, and reduced wear and tear.

6. Integration with Equipment Management Systems:

– Telematics and remote monitoring systems can be integrated with broader equipment management systems. This integration allows hydraulic cylinder data to be correlated with data from other components or related machinery, providing a comprehensive view of the overall system’s performance. This holistic approach enables operators to identify potential interdependencies, optimize system-wide performance, and make informed decisions regarding maintenance, repairs, or upgrades.

7. Enhanced Safety and Fault Diagnosis:

– Telematics and remote monitoring can contribute to enhanced safety and fault diagnosis in hydraulic systems. Real-time data from hydraulic cylinders can be used to detect abnormal conditions, such as excessive pressure or temperature, which may indicate potential safety risks. Fault diagnosis algorithms can analyze the data to identify specific issues or malfunctions, enabling prompt intervention and reducing the risk of catastrophic failures or accidents.

In summary, hydraulic cylinders can be effectively integrated with modern telematics and remote monitoring systems. This integration enables the collection of real-time data, remote monitoring of performance, condition monitoring, predictive maintenance, performance optimization, integration with equipment management systems, and enhanced safety. By harnessing the power of telematics and remote monitoring, hydraulic cylinder users can achieve improved efficiency, reduced downtime, optimized maintenance practices, and enhanced overall productivity in various applications and industries.

Ensuring Controlled and Safe Force Application in Heavy Machinery with Hydraulic Cylinders

Hydraulic cylinders play a critical role in heavy machinery by ensuring controlled and safe force application. The ability to exert and control high forces is essential for heavy machinery operations, such as lifting, pressing, pushing, or pulling heavy loads. Let’s explore how hydraulic cylinders ensure controlled and safe force application in heavy machinery:

- Force Control: Hydraulic cylinders provide precise force control capabilities. The hydraulic system’s pressure can be adjusted to regulate the force exerted by the cylinder. This control allows operators to apply the necessary force for a specific task while ensuring it remains within safe limits. By accurately controlling the force, hydraulic cylinders help prevent excessive force that could damage the machinery or compromise the safety of the operation.

- Load Balancing: In heavy machinery, multiple hydraulic cylinders are often used in conjunction to distribute and balance the applied force. By using multiple cylinders, the load can be evenly distributed across the machinery, minimizing stress concentrations and ensuring controlled force application. This load balancing approach enhances the stability and safety of the machinery, preventing uneven loading that could lead to structural issues or instability.

- Safety Valves: Hydraulic systems in heavy machinery are equipped with safety valves to protect against excessive force or overloading. Safety valves are designed to release hydraulic fluid from the cylinder when the force exceeds a predetermined threshold. This prevents the force from reaching dangerous levels, safeguarding the machinery and preventing potential accidents or damage. Safety valves provide an additional layer of safety and ensure controlled force application even in unexpected circumstances.

- Pressure Relief Systems: Hydraulic cylinders incorporate pressure relief systems to further enhance safety. These systems are designed to relieve excess pressure in the hydraulic system, which could occur due to factors such as thermal expansion or system malfunctions. By relieving excess pressure, the pressure relief systems prevent sudden and uncontrolled force surges, maintaining safe and controlled force application in heavy machinery.

- Structural Integrity: Hydraulic cylinders are designed to withstand the high forces and loads associated with heavy machinery applications. The cylinders are constructed using robust materials, such as high-strength steel, and undergo rigorous testing to ensure their structural integrity. This ensures that the cylinders can safely handle the forces applied during heavy machinery operations without experiencing failures or deformations that could compromise the safety and controlled force application.

In summary, hydraulic cylinders ensure controlled and safe force application in heavy machinery through force control, load balancing, safety valves, pressure relief systems, and robust structural design. These features and design considerations enable operators to exert the necessary force while maintaining safety and preventing excessive loads or force surges. By incorporating hydraulic cylinders into heavy machinery, manufacturers can achieve controlled force application, enhance operational safety, and protect the machinery from damage or failure.

What is a hydraulic cylinder and how does it function in various applications?

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy into linear force and motion. It plays a critical role in various applications where controlled and powerful linear motion is required. Hydraulic cylinders are commonly used in industries such as construction, manufacturing, agriculture, and transportation. Here’s a detailed explanation of what a hydraulic cylinder is and how it functions:

Definition and Components:

– A hydraulic cylinder consists of a cylindrical barrel, a piston, a piston rod, and various seals. The barrel is a hollow tube that houses the piston and allows for fluid flow. The piston divides the cylinder into two chambers: the rod side and the cap side. The piston rod extends from the piston and provides a connection point for external loads. Seals are used to prevent fluid leakage and maintain hydraulic pressure within the cylinder.

Function: