Product Description

Product Description

1.Floor plate style design, more suitable for low ceiling workshop 2. Complete streel welding performance more ad cantage 3.Symmetric arms dabber welding make more stable 4.Adopt quality pack power, more endurable, running safely and reliably 5.Strip design,elegant appearance

|

Model |

MS-4000BM |

MS-5000BM |

|

Lifting weight(t) |

4 |

5 |

|

Overall width(mm) |

3370 |

3420 |

|

Overall height(mm) |

2776 |

2800 |

|

Lifting height(mm) |

1850 |

1800 |

|

Lane width(mm) |

2772 |

2798 |

|

Motor power(kw) |

2.2 |

2.2 |

|

Voltage(v) |

110/220/380 |

110/220/380 |

|

Gross weight(control box weight)kg |

35 |

35 |

|

(Machine weight)kg |

535 |

700 |

|

Packing size(mm) |

2800*530*720 |

2820*450*750 |

|

|

860*260*330 |

850*260*240 |

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

ZheJiang Maysun Machinery Co., Ltd. is located in HangZhou City, ZheJiang Province. It is a technology-based enterprise integrating research and development, sales and service of branch crusher, copper wire granulator, pile driver and hydraulic scissor lift. Over the years, Maysun Machinery has been committed to the field of new energy, has solved the integration of the supply quantity of pile driver for solar energy, electric pile driver, self-propelled hydraulic scissor lift, etc., to provide customers at home and abroad with the best quality products and professional services, the products have been sold to Europe, America, Southeast Asia and Africa and other more than 50 countries and regions of the, won a good reputation.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to Domestic Market(45.00%),Southeast Asia(20.00%),Africa(15.00%),South America(10.00%),Eastern Europe(10.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Dust Removal Equipment, Hydraulic Scissor Lift, Copper Wire Granulator, Pile Breaking Machine, Power Trowel

4. why should you buy from us not from other suppliers?

To provide customers at home and abroad with the best quality products and professional services, the products have been sold to Europe, America, Southeast Asia and Africa and other more than 50 countries and regions of the, won a good reputation.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C;

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Four Cylinder Hydraulic Lift |

| Samples: |

US$ 1720/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

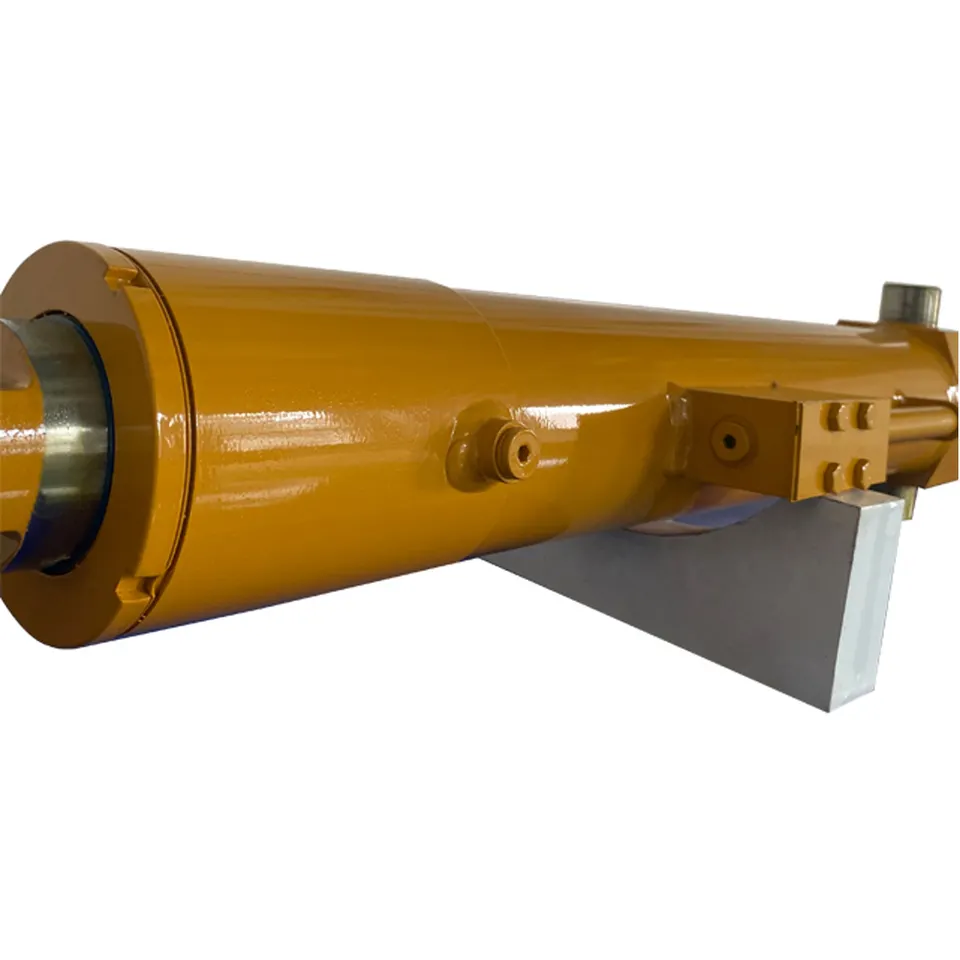

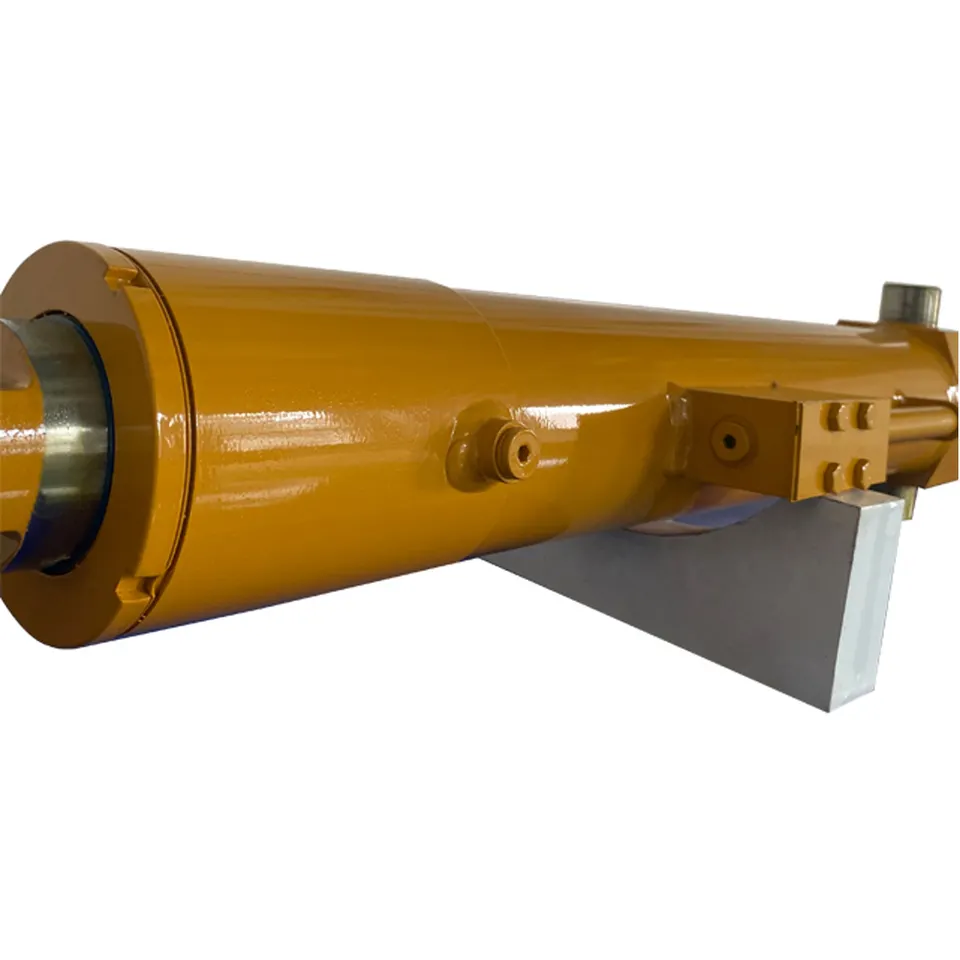

How does a lift cylinder contribute to efficient and reliable lifting?

A lift cylinder plays a crucial role in enabling efficient and reliable lifting operations. Here’s an explanation of how a lift cylinder contributes to efficient and reliable lifting:

1. High Lifting Capacity:

Lift cylinders are specifically designed to provide high lifting capacities. They can generate substantial force to lift heavy loads, making them well-suited for material handling tasks that involve large or bulky items. The high lifting capacity ensures that the cylinder can effectively handle the intended load, contributing to efficient lifting without the need for additional equipment or manual labor.

2. Precise Control:

Lift cylinders offer precise control over the lifting process. By regulating the flow and pressure of hydraulic fluid, operators can achieve accurate positioning and controlled movements. This level of control allows for efficient and precise placement of the load, reducing the risk of damage to the load or surrounding objects. The precise control also enables operators to optimize the lifting process, saving time and effort.

3. Smooth and Stable Operation:

Lift cylinders provide smooth and stable operation during lifting operations. The hydraulic system ensures that the lifting motion is steady and controlled, minimizing jerking or sudden movements. This smooth operation is important for the safe handling of delicate or fragile materials. It also enhances operator confidence and reduces the risk of accidents, contributing to reliable lifting performance.

4. Quick Response Time:

Lift cylinders offer quick response times, allowing for efficient and timely lifting operations. When activated, the hydraulic system quickly directs fluid into the cylinder, initiating the lifting motion. This rapid response time reduces downtime and enables operators to complete lifting tasks more efficiently.

5. Durability and Reliability:

Lift cylinders are built to withstand the demands of heavy-duty lifting operations. They are constructed with durable materials and designed to handle repetitive lifting tasks over extended periods. The robust construction and reliable performance of lift cylinders ensure that they can consistently deliver efficient lifting performance without frequent breakdowns or malfunctions.

6. Safety Features:

Lift cylinders often incorporate safety features to enhance reliability during lifting operations. These features can include load-holding valves, pressure relief valves, and fail-safe mechanisms. Load-holding valves prevent the load from dropping in the event of hydraulic pressure loss, ensuring the load remains securely lifted. Pressure relief valves protect the system from excessive pressure, preventing potential damage. Fail-safe mechanisms provide additional safety by engaging in the event of a system failure or power loss. The presence of these safety features contributes to reliable and safe lifting operations.

7. Integration with Control Systems:

Advanced lift cylinders can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs). This integration allows for automation and optimized control of the lifting process. By incorporating sensors, feedback mechanisms, and pre-programmed sequences, the lift cylinder can operate efficiently and reliably with minimal operator intervention.

In summary, a lift cylinder contributes to efficient and reliable lifting through its high lifting capacity, precise control, smooth and stable operation, quick response time, durability and reliability, incorporation of safety features, and integration with control systems. These features and capabilities ensure that the lifting process is efficient, accurate, and safe, thereby enhancing overall lifting performance.

How does a lift cylinder handle variations in cylinder stroke length?

A lift cylinder is designed to handle variations in cylinder stroke length through its adjustable rod or piston. The stroke length refers to the distance the cylinder can extend or retract, and it can be adjusted to meet specific requirements in different applications.

In hydraulic lift cylinders, the stroke length can be modified by adjusting the position of the rod or piston within the cylinder. This adjustment is typically achieved by adding or removing spacers or by using adjustable stops. By changing the effective length of the cylinder, the stroke can be increased or decreased accordingly.

The adjustment of the stroke length allows the lift cylinder to accommodate different operational needs. For example, in material handling applications, where varying load sizes are encountered, the stroke length can be adjusted to ensure that the cylinder extends or retracts precisely to the required position. This flexibility enables the lift cylinder to handle a wide range of loads and adapt to different lifting or pushing scenarios.

In addition to adjusting the stroke length, lift cylinders often incorporate position feedback mechanisms. These mechanisms, such as linear transducers or position sensors, provide real-time feedback on the actual position of the cylinder. By monitoring the position, the control system can ensure accurate and precise control over the cylinder’s movement, regardless of the stroke length.

The ability to handle variations in cylinder stroke length is crucial in many industrial applications. It allows for adaptability, efficiency, and improved performance in tasks such as material handling, assembly, and automation. By adjusting the stroke length, lift cylinders can optimize their operation, ensuring that the required force and movement are achieved consistently.

In summary, lift cylinders handle variations in cylinder stroke length through adjustable rods or pistons. This adjustment capability, combined with position feedback mechanisms, enables precise control and adaptability in different applications. By accommodating different stroke lengths, lift cylinders can effectively meet the specific requirements of a wide range of industrial tasks.

Can lift cylinders be customized for specific lifting equipment?

Yes, lift cylinders can be customized for specific lifting equipment to meet the unique requirements of different applications. Here’s an explanation of how lift cylinders can be customized:

Lift cylinders are designed to be versatile and adaptable, making them suitable for a wide range of lifting applications. However, certain lifting equipment may have specific needs or constraints that require customization of the lift cylinders. Here are some ways lift cylinders can be customized:

1. Load Capacity:

Lift cylinders can be customized to accommodate different load capacities. The size and specifications of the cylinder, such as the diameter of the piston and the pressure rating, can be adjusted to match the lifting equipment’s specific load requirements. This ensures that the lift cylinder can handle the intended load safely and efficiently.

2. Mounting Options:

The mounting configuration of a lift cylinder can be customized to suit the specific lifting equipment. Different types of mounting options, such as flange mounts, clevis mounts, or trunnion mounts, can be designed and integrated into the cylinder to ensure proper attachment and alignment with the equipment.

3. Stroke Length:

The stroke length of a lift cylinder can be customized to meet the lifting equipment’s vertical travel requirements. By adjusting the length of the piston rod or modifying the cylinder’s dimensions, the stroke length can be tailored to achieve the desired lifting range for the equipment.

4. Operating Speed:

In some cases, the operating speed of the lift cylinder may need to be customized. The hydraulic system parameters, such as the flow rate and valve settings, can be adjusted to control the extension and retraction speed of the cylinder. This customization ensures that the lifting equipment operates at the desired speed for efficient and precise lifting.

5. Environmental Considerations:

For lifting equipment used in specific environments, such as extreme temperatures, corrosive atmospheres, or hazardous conditions, lift cylinders can be customized to withstand these conditions. Special materials, coatings, or seals can be employed to enhance the cylinder’s durability and resistance to environmental factors.

6. Integration with Control Systems:

Customized lift cylinders can be integrated with control systems and automation technologies specific to the lifting equipment. This integration enables precise control, synchronized movements, and seamless integration with other equipment or processes, optimizing the overall performance and efficiency of the lifting system.

In summary, lift cylinders can be customized for specific lifting equipment by adjusting load capacity, mounting options, stroke length, operating speed, considering environmental factors, and integrating with control systems. Customization ensures that the lift cylinders are tailored to meet the unique requirements of the lifting equipment, enabling safe, efficient, and reliable lifting operations.

editor by CX 2024-04-03

China supplier 24V DC Drive Switch-Type Electric Driven Hydraulic Cylinder vacuum pump distributors

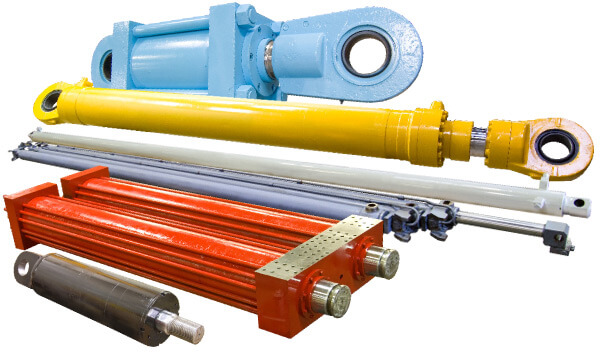

Product Description

Electric driven hydraulic cylinder is highly integrated products, the servo motor (or 24v DC motor), pump, hydraulic valve, tank, sensor (when needed), controller (when needed), pipeline, etc. are integrated on the cylinder, it can work when electricity and control signal input are provided, no need of other pipeline, sensors, valve set, pump station and other equipment.

The advantages:

Compared with hydraulic system of traditional pump station + valve set + multiple hydraulic cylinder + controller, Electric driven hydraulic cylinder has the following advantages

1.Simple connection: front and rear support ear connection, power supply and control cable can be inserted to use;

2. Easy to use: no need to pay attention to pipe, pump station installation form and space problems;3.Simple control: built-in control software, in place to automatically stop, can greatly simplify the workload of user software;

3. Small volume and weight: save the controller, pipeline, pipe card, bracket and other accessories, can reduce the total weight of the hydraulic system;

4. More independent: between the multiple hydraulic cylinders are completely independent, can cooperate with each other to complete a certain action;

5. More energy saving: hydraulic cylinder with perfectly matched pump control hydraulic system, reduce the throttle loss of the valve; the motor automatically stop when not working, reduce the overflow loss; basically no pipeline, reduce the loss along the line;

6. Eliminate leakage: the cylinder equipped with hard pipe, greatly reduce the hydraulic connection point, will minimize the possibility of leakage;

24V DC drive switch-type hydraulic cylinder

Main parameters

| Performance parameter | Speed mm/s | Dimensions | Mounting distance | Weight(kg,Earrings) | ||||||||||

| Bore Dia. | Outer Dia. | Push | Stroke | Extend | Retract | Height | Width | Flange | Earrings | Rod dia. | Stroke | Stroke factor | weight | |

| 1 | 40 | 55 | 2 | 600 | 32 | 53 | 145 | 80 | S+160 | S+250 | 20 | 10.5 | 0.0127 | 18.1 |

| 2 | 50 | 65 | 3 | 500 | 21 | 30 | 155 | 80 | S+160 | S+250 | 25 | 11.0 | 0.0155 | 18.8 |

| 3 | 63 | 80 | 5 | 300 | 13 | 19 | 170 | 80 | S+160 | S+250 | 30 | 13.0 | 0.0185 | 18.6 |

| 4 | 80 | 95 | 8 | 1000 | 20 | 27 | 220 | 110 | S+160 | S+250 | 40 | 22.0 | 0.5713 | 50.3 |

| 5 | 90 | 106 | 10 | 800 | 16 | 21 | 231 | 110 | S+160 | S+250 | 40 | 25.6 | 0.032 | 51.2 |

| 6 | 100 | 118 | 15 | 600 | 13 | 17 | 243 | 110 | S+160 | S+250 | 50 | 31.3 | 0. 0571 | 55.0 |

| 7 | 110 | 127 | 20 | 700 | 14 | 20 | 272 | 130 | S+160 | S+250 | 50 | 41.2 | 0.047 | 74.1 |

| 8 | 125 | 146 | 26 | 600 | 11 | 15 | 291 | 130 | S+160 | S+250 | 60 | 50.5 | 0.571 | 86.2 |

Q1. Are you a manufacturer?

Yes, we have manufactured hydraulic cylinders for over 30 years. They are widely used in Engineers, Coal&mine, Agriculture and Environmental Sanitation etc.

Q2. Do your products come with a warranty?

Yes, we have 1 year warranty.

Q3. Can we customize our products from you?

Yes, actually 70% of our products are customized for our clients. You just need to let us know your demand (specifications &drawing is better), and we shall realize them for you.

Q4. How do you deliver the products?

By sea, by plane, or by couriers.

Q5. How many days the samples can be finished, And how about the mass production?

Generally 5-7days for samples making. The lead time of mass production will depend on quality, production art and so on. Generally 35days.

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | -40~120 |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Structure: | Piston Type |

| Customization: |

Available

|

|

|---|

How do hydraulic cylinders handle the challenges of precise positioning and control?

Hydraulic cylinders are designed to handle the challenges of precise positioning and control with a combination of engineering principles and advanced control systems. These challenges often arise in applications where accurate and controlled movements are required, such as in industrial automation, construction, and material handling. Here’s a detailed explanation of how hydraulic cylinders overcome these challenges:

1. Fluid Power Control:

– Hydraulic cylinders utilize fluid power control to achieve precise positioning and control. The hydraulic system consists of a hydraulic pump, control valves, and hydraulic fluid. By regulating the flow of hydraulic fluid into and out of the cylinder, operators can control the speed, direction, and force exerted by the cylinder. The fluid power control allows for smooth and accurate movements, enabling precise positioning of the hydraulic cylinder and the attached load.

2. Control Valves:

– Control valves play a crucial role in handling the challenges of precise positioning and control. These valves are responsible for directing the flow of hydraulic fluid within the system. They can be manually operated or electronically controlled. Control valves allow operators to adjust the flow rate of the hydraulic fluid, controlling the speed of the cylinder’s movement. By modulating the flow, operators can achieve fine control over the positioning of the hydraulic cylinder, enabling precise and accurate movements.

3. Proportional Control:

– Hydraulic cylinders can be equipped with proportional control systems, which offer enhanced precision in positioning and control. Proportional control systems utilize electronic feedback and control algorithms to precisely regulate the flow and pressure of the hydraulic fluid. These systems provide accurate and proportional control over the movement of the hydraulic cylinder, allowing for precise positioning at various points along its stroke length. Proportional control enhances the cylinder’s ability to handle complex tasks that require precise movements and control.

4. Position Feedback Sensors:

– To achieve precise positioning, hydraulic cylinders often incorporate position feedback sensors. These sensors provide real-time information about the position of the cylinder’s piston rod. Common types of position feedback sensors include potentiometers, linear variable differential transformers (LVDTs), and magnetostrictive sensors. By continuously monitoring the position, the feedback sensors enable closed-loop control, allowing for accurate positioning and control of the hydraulic cylinder. The feedback information is used to adjust the flow of hydraulic fluid to achieve the desired position accurately.

5. Servo Control Systems:

– Advanced hydraulic systems employ servo control systems to handle the challenges of precise positioning and control. Servo control systems combine electronic control, position feedback sensors, and proportional control valves to achieve high levels of accuracy and responsiveness. The servo control system continuously compares the desired position with the actual position of the hydraulic cylinder and adjusts the flow of hydraulic fluid to minimize any positional error. This closed-loop control mechanism enables the hydraulic cylinder to maintain precise positioning and control, even under varying loads or external disturbances.

6. Integrated Automation:

– Hydraulic cylinders can be integrated into automated systems to achieve precise positioning and control. In such setups, the hydraulic cylinders are controlled by programmable logic controllers (PLCs) or other automation controllers. These controllers receive input signals from various sensors and use pre-programmed logic to command the hydraulic cylinder’s movements. The integration of hydraulic cylinders into automated systems allows for precise and repeatable positioning and control, enabling complex sequences of movements to be executed with high accuracy.

7. Advanced Control Algorithms:

– Advancements in control algorithms have also contributed to the precise positioning and control of hydraulic cylinders. These algorithms, such as PID (Proportional-Integral-Derivative) control, adaptive control, and model-based control, enable sophisticated control strategies to be implemented. These algorithms consider factors such as load variations, system dynamics, and environmental conditions to optimize the control of hydraulic cylinders. By employing advanced control algorithms, hydraulic cylinders can compensate for disturbances and achieve precise positioning and control over a wide range of operating conditions.

In summary, hydraulic cylinders overcome the challenges of precise positioning and control through the use of fluid power control, control valves, proportional control, position feedback sensors, servo control systems, integrated automation, and advanced control algorithms. By combining these elements, hydraulic cylinders can achieve accurate and controlled movements, enabling precise positioning and control in various applications. These capabilities are essential for industries that require high precision and repeatability in their operations, such as industrial automation, robotics, and material handling.

Adaptation of Hydraulic Cylinders for Medical Equipment and Aerospace Applications

Hydraulic cylinders have the potential to be adapted for use in medical equipment and aerospace applications, offering unique advantages in these industries. Let’s explore how hydraulic cylinders can be adapted for these specialized fields:

- Medical Equipment: Hydraulic cylinders can be adapted for various medical equipment applications, including hospital beds, patient lifts, surgical tables, and rehabilitation devices. Here’s how hydraulic cylinders are beneficial in medical equipment:

- Positioning and Adjustability: Hydraulic cylinders provide precise and smooth movement, allowing for accurate positioning and adjustments of medical equipment. This is crucial for ensuring patient comfort, proper alignment, and ease of use.

- Load Handling: Hydraulic cylinders offer high force capabilities, enabling the safe handling of heavy loads in medical equipment. They can support the weight of patients, facilitate smooth transitions, and provide stability during procedures.

- Controlled Motion: Hydraulic cylinders provide controlled and stable motion, which is essential for delicate medical procedures. The ability to adjust speed, position, and force allows for precise and controlled movements, minimizing patient discomfort and ensuring accurate treatment.

- Durability and Reliability: Hydraulic cylinders are designed to withstand rigorous use and demanding environments, making them suitable for medical equipment applications. Their durability and reliability contribute to the long-term performance and safety of medical devices.

- Aerospace Applications: Hydraulic cylinders can also be adapted for aerospace applications, where lightweight yet robust systems are essential. Here’s how hydraulic cylinders are advantageous in aerospace:

- Flight Control Systems: Hydraulic cylinders play a critical role in aircraft flight control systems, including ailerons, elevators, rudders, and landing gear. They provide precise and reliable actuation, allowing pilots to control the aircraft’s movements with accuracy and responsiveness.

- Weight Optimization: Hydraulic cylinders can be designed using lightweight materials, such as aluminum alloys or composite materials, to reduce overall weight. This weight optimization is crucial in aerospace applications to enhance fuel efficiency, payload capacity, and aircraft performance.

- Shock and Vibration Resistance: Aerospace environments involve significant shock and vibration forces. Hydraulic cylinders can be engineered to withstand these dynamic loads while maintaining performance and reliability, ensuring consistent operation even under extreme conditions.

- Space Constraints: Hydraulic cylinders can be designed to fit within the space constraints of aircraft or spacecraft. Their compact size and flexible mounting options allow for efficient integration into the limited available space.

In summary, hydraulic cylinders can be adapted for use in medical equipment and aerospace applications, leveraging their precise positioning, load handling capabilities, controlled motion, durability, and reliability. In medical equipment, hydraulic cylinders enable comfortable patient positioning, smooth transitions, and controlled movements during procedures. In aerospace, hydraulic cylinders provide precise actuation, weight optimization, shock and vibration resistance, and space-efficient solutions. By adapting hydraulic cylinders to these specialized fields, manufacturers can meet the unique requirements and enhance the performance of medical equipment and aerospace systems.

What is a hydraulic cylinder and how does it function in various applications?

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy into linear force and motion. It plays a critical role in various applications where controlled and powerful linear motion is required. Hydraulic cylinders are commonly used in industries such as construction, manufacturing, agriculture, and transportation. Here’s a detailed explanation of what a hydraulic cylinder is and how it functions:

Definition and Components:

– A hydraulic cylinder consists of a cylindrical barrel, a piston, a piston rod, and various seals. The barrel is a hollow tube that houses the piston and allows for fluid flow. The piston divides the cylinder into two chambers: the rod side and the cap side. The piston rod extends from the piston and provides a connection point for external loads. Seals are used to prevent fluid leakage and maintain hydraulic pressure within the cylinder.

Function:

– The function of a hydraulic cylinder is to convert the pressure and flow of hydraulic fluid into linear force and motion. The hydraulic fluid, typically oil, is pressurized and directed into one of the chambers of the cylinder. As the fluid enters the chamber, it applies pressure on the piston, causing it to move in a linear direction. This linear motion of the piston is transferred to the piston rod, creating a pushing or pulling force.

Working Principle:

– The working principle of a hydraulic cylinder is based on Pascal’s law, which states that pressure exerted on a fluid in a confined space is transmitted equally in all directions. In a hydraulic cylinder, when hydraulic fluid is pumped into one side of the cylinder, it creates pressure on the piston. The pressure is transmitted through the fluid to the other side of the piston, resulting in a balanced force across the piston and piston rod. This force generates linear motion in the direction determined by the fluid input.

Applications:

– Hydraulic cylinders find extensive use in a wide range of applications due to their ability to generate high forces and precise control of linear motion. Some common applications include:

1. Construction Equipment: Hydraulic cylinders are used in excavators, loaders, bulldozers, and cranes for lifting, pushing, and digging tasks.

2. Manufacturing Machinery: Hydraulic cylinders are employed in presses, machine tools, and material handling equipment for pressing, clamping, and lifting operations.

3. Agricultural Machinery: Hydraulic cylinders are used in tractors, harvesters, and irrigation systems for tasks like steering, lifting, and controlling attachments.

4. Transportation: Hydraulic cylinders are utilized in vehicles such as dump trucks, garbage trucks, and forklifts for tilting, lifting, and tipping operations.

5. Aerospace and Defense: Hydraulic cylinders are employed in aircraft landing gear, missile systems, and hydraulic actuators for control surfaces.

6. Marine and Offshore: Hydraulic cylinders are used in ship steering systems, cranes, and offshore drilling equipment for various lifting and positioning tasks.

In these applications, hydraulic cylinders offer advantages such as high force capability, precise control, compact size, and durability. They provide efficient and reliable linear motion, contributing to enhanced productivity and functionality in a wide range of industries.

Overall, hydraulic cylinders are integral components in various applications where controlled and powerful linear motion is required. Their ability to convert hydraulic energy into mechanical force makes them invaluable in numerous industries, enabling the operation of heavy machinery, precise positioning, and efficient load handling.

editor by CX 2023-10-26