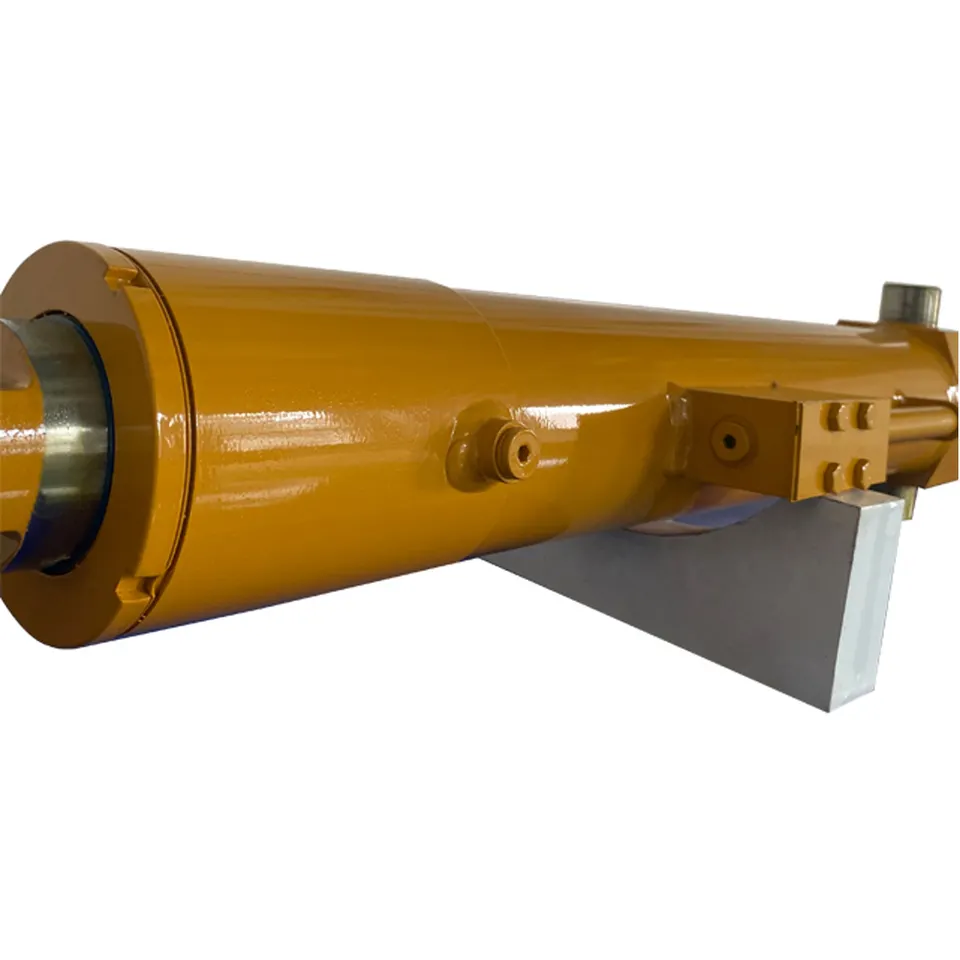

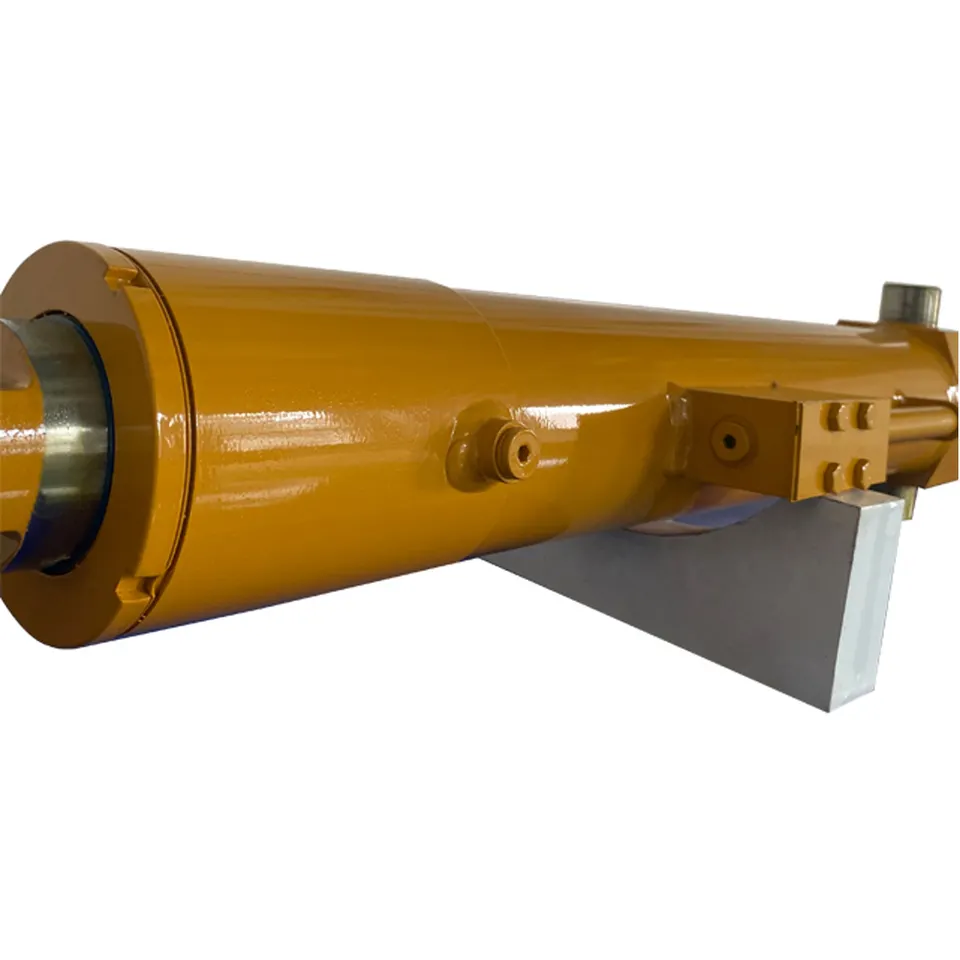

Product Description

Specifications:

| Product Name | HSG Series Hydraulic Cylinder |

| Work Press | 7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

| Material | Aluminum, Cast Iron,45mnb Steel, Stainless Steel |

| Bore Size | 40mm–320mm, Customizable |

| Shaft Diameter | 20mm–220mm, Customizable |

| Stroke Length | 30mm–14100mm, Customizable |

| Rod Surface Hardness | HRC48-54 |

| Operating Temperature | -40°C to +120 °C |

| Paint Color | Black, Yellow, Blue, Brown, Customizable |

| Service | OEM&ODM |

| Warranty | 1 Year |

| MOQ | 1 Piece |

| Delivery Time | 7-15 Days, Also depending on specific demands |

| Certification | ISO9001,CE |

| Capacity | 50,000Pcs per year |

Product Display:

Mounting:

Working Flow: About Us

Tongte designs and manufactures durable, heavy-duty hydraulic products and accessories and offers lifecycle services to them. We constantly develop our machine base and operations to meet customer-specific needs and remain leaders in the industry. Beyond all else, we want to be the trusted, groundbreaking partner our customers truly need.

In addition to the customized cylinders, CHINAMFG offers hydraulic power units, Electric-Hydraulic linear actuators, piston accumulators, system configurations, and versatile services such as repair and manufacturing services. The modern production facilities are located in HangZhou, ZheJiang (China) where production started in 2001. The core values of Tongke guiding its business strongly are commitment, sustainability, interaction, and customer-first.

We possess over 20 years of experience in the industry and extensive global market experience, our customers are located all over the world, and we truly commit to the customers’ needs – these are the success factors of our family-owned company. Our vision is to grow and expand the business further into global markets.

FAQ:

Q1: What does your company do?

A: we are a supplier of high-quality hydraulic products including Hydraulic Cylinders, Hydraulic Power packs, Hydraulic Linear, and other Hydraulic components.

Q2:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q3:Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, and 15-30 working days if we don’t. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What is your warranty policy?

A: All our products are warranted for 1 full year from the date of delivery against defects in materials and workmanship. Each individual product will be strictly inspected on our factory QC Process

System before shipment. We also have a Customer Service team to respond to customers’ questions within 12 hours. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lift cylinders be used in dock levelers and loading ramps?

Yes, lift cylinders can be used in dock levelers and loading ramps. Here’s an explanation of their utilization in these applications:

Dock levelers and loading ramps are essential equipment in logistics and transportation facilities, allowing for efficient loading and unloading of goods between trucks and loading docks. Lift cylinders play a crucial role in these systems by providing the necessary lifting and positioning capabilities.

In dock levelers, lift cylinders are employed to bridge the gap between the loading dock and the truck bed, ensuring a smooth transition for material handling equipment such as forklifts or pallet jacks. These cylinders are typically integrated into the mechanical or hydraulic systems of the dock leveler, allowing for controlled vertical movement. By extending or retracting the lift cylinders, the dock leveler can be adjusted to match the height of the truck bed, enabling safe and efficient loading or unloading of cargo.

Loading ramps, also known as mobile yard ramps or portable ramps, are used in situations where a permanent loading dock is not available or when additional flexibility is required. Lift cylinders are utilized in loading ramps to provide the means for height adjustment and inclination control. By extending or retracting the lift cylinders, the ramp can be raised or lowered to align with the truck bed height, facilitating the movement of goods between the ramp and the truck.

The use of lift cylinders in dock levelers and loading ramps ensures precise and controlled positioning during the loading and unloading process. Operators can adjust the lift cylinders to match the specific height requirements, allowing for smooth and safe transfer of materials without causing damage to the goods or the equipment.

Lift cylinders used in dock levelers and loading ramps are designed to withstand heavy loads and endure frequent use. They are constructed with robust materials and incorporate features such as seals and bearings to ensure durability and reliability in demanding industrial environments.

Furthermore, lift cylinders in dock levelers and loading ramps may incorporate safety features such as automatic descent control or velocity fuses. These safety mechanisms help prevent sudden drops or uncontrolled movements in the event of a hydraulic system failure, enhancing the overall safety of the loading and unloading operations.

In summary, lift cylinders are commonly utilized in dock levelers and loading ramps to provide reliable and controlled lifting and positioning capabilities. Their ability to handle heavy loads, facilitate height adjustment, and incorporate safety features makes them integral components in these applications, contributing to efficient and safe material handling operations.

Can lift cylinders be used in agricultural machinery and equipment?

Yes, lift cylinders are commonly used in agricultural machinery and equipment. Here’s an explanation of their utilization in this context:

Agricultural machinery and equipment often require lifting capabilities to perform various tasks such as loading, lifting, and adjusting components. Lift cylinders provide the necessary force and control to accomplish these operations effectively.

1. Tractors and Loaders:

Lift cylinders are extensively used in agricultural tractors and loaders. These cylinders are typically integrated into the hydraulic systems of the equipment and are responsible for lifting and lowering front-end attachments, such as buckets, forks, or blades. By extending and retracting the lift cylinders, operators can control the height and position of the attachments, enabling efficient material handling, loading, and leveling tasks.

2. Harvesting and Threshing Equipment:

In harvesting and threshing equipment, lift cylinders are employed to adjust and control the height of components such as headers, cutter bars, or platforms. These cylinders enable operators to adapt to different crop heights and ground conditions, ensuring optimal harvesting performance. By utilizing lift cylinders, agricultural machinery can effectively navigate uneven terrain and maintain consistent cutting or harvesting heights.

3. Sprayers and Spreaders:

Lift cylinders are also utilized in agricultural sprayers and spreaders. These cylinders are responsible for raising and lowering the booms or spreading mechanisms. By adjusting the lift cylinders, operators can control the application height or spreading width, ensuring precise and uniform coverage of fertilizers, pesticides, or seeds.

4. Irrigation Systems:

In irrigation systems, lift cylinders are used to control the height and position of irrigation equipment such as sprinklers or pivots. These cylinders allow for efficient adjustment of the irrigation components to ensure optimal water distribution across agricultural fields.

5. Implements and Attachments:

Lift cylinders are widely employed in various agricultural implements and attachments, including plows, harrows, cultivators, and seed drills. These cylinders facilitate the lifting and lowering of the implements, allowing for depth adjustments, ground clearance, and transport modes. Lift cylinders enhance the versatility and functionality of agricultural equipment, enabling farmers to efficiently perform a wide range of field operations.

In summary, lift cylinders have significant applications in agricultural machinery and equipment. They contribute to the lifting, lowering, and positioning tasks required for efficient material handling, leveling, harvesting, spreading, and irrigation operations. By utilizing lift cylinders, agricultural equipment becomes more versatile, productive, and adaptable to the specific needs of farmers and agricultural practices.

What industries commonly use lift cylinders in their applications?

Lift cylinders, also known as hydraulic lift cylinders or hydraulic lifting cylinders, find applications in various industries where lifting, lowering, and vertical motion are required. Here are some industries that commonly use lift cylinders:

1. Material Handling and Logistics:

Lift cylinders are extensively used in material handling and logistics industries. They are employed in equipment such as forklifts, pallet jacks, and reach trucks to lift and lower loads, enabling efficient movement and storage of goods in warehouses, distribution centers, and manufacturing facilities.

2. Construction and Heavy Machinery:

In the construction industry, lift cylinders are utilized in equipment such as cranes, excavators, loaders, and scissor lifts. They provide the necessary lifting force to handle heavy materials, perform lifting operations at construction sites, and facilitate the movement of equipment and materials in challenging environments.

3. Automotive and Transportation:

In the automotive and transportation sectors, lift cylinders are used in applications such as vehicle lifts, car hoists, and hydraulic ramps. These cylinders enable the lifting and lowering of vehicles for maintenance, repair, and inspection purposes, ensuring efficient and safe operations in automotive workshops, garages, and service stations.

4. Aerospace and Aviation:

Lift cylinders play a critical role in the aerospace and aviation industries. They are employed in aircraft maintenance lifts, ground support equipment, and hydraulic systems for aircraft doors and landing gear. Lift cylinders enable the precise positioning and movement of aircraft components, ensuring safe and reliable operations in the aviation sector.

5. Manufacturing and Industrial Equipment:

In manufacturing and industrial settings, lift cylinders are utilized in a wide range of applications. They are used in hydraulic presses, machine tools, assembly lines, and industrial lifts to provide the necessary vertical motion for lifting, positioning, and manipulating various components and materials in production processes.

6. Healthcare and Medical Equipment:

Lift cylinders find applications in the healthcare industry, particularly in medical equipment such as patient lifts, hospital beds, and examination tables. These cylinders enable safe patient handling and positioning, facilitating caregiver tasks and ensuring patient comfort and mobility.

These are just a few examples of industries that commonly use lift cylinders in their applications. The versatility and reliability of lift cylinders make them valuable components in numerous sectors where controlled vertical motion and lifting capabilities are essential.

editor by CX 2024-04-16

China supplier Office Chair Gas Lift Cylinder Replacement Hydraulic Pneumatic Shock Piston with Hot selling

Product Description

Product Description

Office Chair Gas Lift Cylinder Replacement Universal Size The Gas Lift Cylinder for Standard Chairs on the market We love this Spare Gas Cylinder that fits most executive, computer, and desk chairs. Features – Heavy duty gas lift cylinder. – Made of the highest quality materials available. – Durable and resistant to the greatest weights. – The choice for adults, children and anyone in the family. Benefits – replacement fits most executive, computer and desk chairs sold in The US and Canada. – Very easy hassle-free installation. It will not take more 10 minutes. – The piston stroke goes up and down and smoothly rotates 360 degrees. Highest Quality Gas Cylinder 5 Years Guarantee and No-Hassle Free Replacement Guarantee. Package: – Office Chair Gas Lift Cylinder Replacement. – Large: 15 inches height fully extended. – Width: 2 inches wide. – Stroke extension: 1.1 inches, Highest Quality Click The “Add to Cart” button at the top of this page to start replacing your Office Chair Gas Lift Cylinder THIS HEAVY DUTY GAS LIFT CYLINDER MEETS THE HIGHEST QUALITY STHangZhouRDS, HIGHEST END CLASS 4, MEETS ANSI/BIFMA QUALITY INDUSTRY STHangZhouRDS

| Model | C | S | L | V | X | Y | F1±1KG |

| MX-40mm | 40D | 210 | 250 | 135 | 60 | 10 | 500 |

| MX-65mm | 65D | 215 | 280 | 160 | 60 | 10 | 480/550 |

| MX-85mm | 85D | 235 | 320 | 175 | 60 | 10 | 400 |

| MX-100mm | 100D | 250 | 360 | 185 | 60 | 10 | 400 |

| MX-120mm | 120D | 270 | 390 | 195 | 60 | 10 | 400 |

| MX-140mm | 140D | 290 | 430 | 225 | 60 | 10 | 380 |

| MX-160mm | 160D | 330 | 510 | 285 | 60 | 10 | 380 |

| MX-200mm | 200D | 360 | 560 | 295 | 60 | 10 | 380 |

| MX-260mm | 260D | 440 | 700 | 365 | 60 | 10 | 380 |

Company Profile

Production Workshop

Packaging & Shipping

Certifications

FAQ

1.Q: What is our factory product range?

A:1)Office chair parts.Such as office chair castor wheel,shaft collar,gas spring for cabinet,office chair gas spring.

2.Q: How to order?

A:Please send us your purchase order by Email or Fax.

1) Product information:Quantitiy,Specification(size , color, logo and packing requirement),

2) Delivery time required.

3) Shipping information:Company name,Address,Phone number,Destination seaport/airport.

4) Forwarder’s contact details if there is any in China.

3.Q: How long and how to get sample from us ?

A:1) If you need some sample to text,we can make as per your request,please provide us PDF or AI for Making.

2) Lead time for making sample:about 7 days

3) The transportation freight of samples: the freight depends on the weight and packing size and your area.

4.Q: What is the payment terms for sample cost and order amount?

A:For sample, we accept the payment sent by West Union,Paypal, for orders, we can accept T/T or L/C at sight.

5.Q: What is the whole process for doing business with us ?

A:1) First,please provide details of the products you need we quote for you.

2) If price is acceptable and client need sample,we provide samples for your reference.

3) If client approve sample and require for bulk production for order,we will provide Proforma Invoice for client,and we will arrange to produce at once when we get 30% deposit.

4) We will send photos of all goods,packing,details,and B/L copy for client after goods are finished.We will arrange shipment and provide original B/L when the client pay the balance.

6.Q: Can the logo or company name to be printed on the products or package?

A:Sure.Your logo or company name can be printed on your products by stamping, printing,embossing,die cast, coating or sticker.

7.Q: What advantages we have?

A:Rich experience: We have more than 10 years experience in this industry.

That means,we can preview the problems for the orders and products.

Therefore,it will make sure to reduce the risk of bad situation to happen.

Point to point service: There is 1 sale who will serve you from inquiry to products shipped out.During the process,you just need to discuss with her for all problems and the way saves much time.

Free design: If you are not ready for the designs,the professional designers will be able to help you with it freely.

Strict QC: For each order,strict inspection will be carried out by the QC department before shipping.The bad quality will be avoid within door.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Function: | Pressed |

|---|---|

| Material: | Stainless Steel |

| Usage: | Industrial, Furniture |

| Load Type: | Compression |

| Production Process: | Hot Roll |

| Shape: | Cylinder |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does a lift cylinder handle variations in fluid pressure and flow rate?

A lift cylinder is designed to handle variations in fluid pressure and flow rate in order to ensure smooth and controlled operation. Here’s an explanation of how lift cylinders handle these variations:

1. Fluid Pressure:

Lift cylinders are typically part of a hydraulic system that utilizes pressurized fluid to generate the necessary force for lifting. The lift cylinder is designed to withstand varying fluid pressure levels. When the fluid pressure is increased, the lift cylinder can handle the additional force exerted on its piston. Conversely, when the fluid pressure decreases, the lift cylinder adjusts accordingly and maintains its functionality.

2. Flow Rate:

The flow rate of hydraulic fluid determines the speed at which the lift cylinder extends or retracts. Lift cylinders are designed to accommodate variations in flow rate. By controlling the flow rate of the hydraulic fluid through the use of control valves or flow control devices, operators can adjust the speed of the lift cylinder’s movement. This allows for precise and controlled lifting operations.

3. Control Valves:

Control valves are an integral part of the hydraulic system that regulates the fluid pressure and flow rate. Lift cylinders are often equipped with control valves that enable operators to control the movement of the cylinder by adjusting the pressure and flow of the hydraulic fluid. These valves can be manually operated or automated, providing flexibility in handling variations in fluid pressure and flow rate.

4. Cylinder Design:

Lift cylinders are designed to be robust and durable, capable of withstanding variations in fluid pressure and flow rate. The cylinder’s construction and materials are selected to ensure optimal performance under different operating conditions. Seals and other components within the lift cylinder are designed to maintain their functionality and prevent leakage, even when subjected to changes in fluid pressure and flow rate.

5. Fluid Control Systems:

In more advanced lift cylinder systems, fluid control systems may be employed to handle variations in fluid pressure and flow rate. These systems can include pressure relief valves, flow control valves, or proportional valves. Pressure relief valves protect the lift cylinder and the hydraulic system from excessive pressure, while flow control valves regulate the flow rate of the hydraulic fluid. Proportional valves provide precise control over both pressure and flow, allowing for fine-tuning of the lift cylinder’s movement.

In summary, lift cylinders are designed to handle variations in fluid pressure and flow rate to ensure smooth and controlled lifting operations. With the use of control valves, robust cylinder design, and fluid control systems, lift cylinders can adapt to changes in fluid pressure and flow rate, providing reliable and efficient performance.

Can lift cylinders be used in agricultural machinery and equipment?

Yes, lift cylinders are commonly used in agricultural machinery and equipment. Here’s an explanation of their utilization in this context:

Agricultural machinery and equipment often require lifting capabilities to perform various tasks such as loading, lifting, and adjusting components. Lift cylinders provide the necessary force and control to accomplish these operations effectively.

1. Tractors and Loaders:

Lift cylinders are extensively used in agricultural tractors and loaders. These cylinders are typically integrated into the hydraulic systems of the equipment and are responsible for lifting and lowering front-end attachments, such as buckets, forks, or blades. By extending and retracting the lift cylinders, operators can control the height and position of the attachments, enabling efficient material handling, loading, and leveling tasks.

2. Harvesting and Threshing Equipment:

In harvesting and threshing equipment, lift cylinders are employed to adjust and control the height of components such as headers, cutter bars, or platforms. These cylinders enable operators to adapt to different crop heights and ground conditions, ensuring optimal harvesting performance. By utilizing lift cylinders, agricultural machinery can effectively navigate uneven terrain and maintain consistent cutting or harvesting heights.

3. Sprayers and Spreaders:

Lift cylinders are also utilized in agricultural sprayers and spreaders. These cylinders are responsible for raising and lowering the booms or spreading mechanisms. By adjusting the lift cylinders, operators can control the application height or spreading width, ensuring precise and uniform coverage of fertilizers, pesticides, or seeds.

4. Irrigation Systems:

In irrigation systems, lift cylinders are used to control the height and position of irrigation equipment such as sprinklers or pivots. These cylinders allow for efficient adjustment of the irrigation components to ensure optimal water distribution across agricultural fields.

5. Implements and Attachments:

Lift cylinders are widely employed in various agricultural implements and attachments, including plows, harrows, cultivators, and seed drills. These cylinders facilitate the lifting and lowering of the implements, allowing for depth adjustments, ground clearance, and transport modes. Lift cylinders enhance the versatility and functionality of agricultural equipment, enabling farmers to efficiently perform a wide range of field operations.

In summary, lift cylinders have significant applications in agricultural machinery and equipment. They contribute to the lifting, lowering, and positioning tasks required for efficient material handling, leveling, harvesting, spreading, and irrigation operations. By utilizing lift cylinders, agricultural equipment becomes more versatile, productive, and adaptable to the specific needs of farmers and agricultural practices.

Can you explain the role of hydraulic fluid in a lift cylinder?

Hydraulic fluid plays a crucial role in the operation of a lift cylinder. It serves as the medium through which force is transmitted to generate motion and provide lifting or lowering capabilities. Here’s an explanation of the role of hydraulic fluid in a lift cylinder:

1. Transmission of Force:

Hydraulic fluid acts as a medium for transmitting force within the lift cylinder. When pressurized, the hydraulic fluid applies force on the piston, which then transfers that force to the load through the rod. The force exerted by the hydraulic fluid is transmitted equally in all directions due to Pascal’s law, allowing for effective lifting or lowering of heavy loads.

2. Energy Transfer:

Hydraulic fluid is responsible for transferring energy within the hydraulic system. The hydraulic fluid is pressurized by a pump, which converts mechanical energy into hydraulic energy. This pressurized fluid carries the energy to the lift cylinder, where it is converted back into mechanical energy to perform the lifting or lowering action. The ability of hydraulic fluid to store and transmit energy efficiently makes it ideal for power transmission in hydraulic systems.

3. Lubrication and Cooling:

Hydraulic fluid serves as a lubricant within the lift cylinder to reduce friction and wear between moving parts, such as the piston and the cylinder barrel. This lubrication helps to enhance the longevity and smooth operation of the cylinder components. Additionally, the hydraulic fluid also aids in cooling the system by absorbing heat generated during operation, preventing overheating and ensuring optimal performance.

4. Sealing and Contamination Control:

Hydraulic fluid plays a critical role in sealing the lift cylinder and preventing leakage. It works in conjunction with seals located between the piston and cylinder barrel, as well as around the rod, to create a tight and secure hydraulic system. The hydraulic fluid also helps to control contamination by keeping external contaminants, such as dirt and debris, from entering the cylinder and affecting its performance.

5. System Efficiency:

The properties of hydraulic fluid, such as its viscosity and flow characteristics, directly impact the efficiency of the lift cylinder system. The choice of the appropriate hydraulic fluid ensures smooth and efficient operation, minimizing energy losses and maximizing system performance.

In summary, hydraulic fluid plays a vital role in a lift cylinder by transmitting force, transferring energy, lubricating and cooling the system, sealing against leaks, controlling contamination, and contributing to system efficiency. It enables the lift cylinder to generate the necessary force and motion to lift or lower heavy loads, while also ensuring the smooth and reliable operation of the hydraulic system.

editor by CX 2024-01-05

China Good quality Hydraulic Gas Lift Cylinder for Office Furniture Executive Lift Mesh Swivel Office Chair vacuum pump design

Product Description

Hydraulic gas lift cylinder for office furniture executive lift mesh swivel office chair

- Product information

- Other Fitness Cylinder

- Specification

|

Material

|

Tube – Cold Drawn / Honed Tubing Piston Rod – Chromed, ground & polished 45#steel Rod Seals – Polyurethane U-Cap End Caps – Steel, threaded fixed Wear Ring – Nylon Backup Washer Mounts – Trunnion with angular Swivels |

|

Application

|

Agriculture, Concrete & Asphalt, Cranes, Fire & Rescue,Forestry & Logging,Mining & Rock Crushing,Oil & Gas,Snow & Ice Control,Waste Management and Material Recycling Industry , Engineering Equipment, Special Vehicle, Fitness equipment

|

|

Feature |

1.High quality with a reasonable price 2.ISO9001-2008 3.Customized specification are accepted |

|

Payment |

T/T;L/C,WESTERN UNION |

|

Port |

HangZhou/ZheJiang , China |

|

Quotation |

According to the specific request |

|

MOQ |

According to the product |

|

Packaging

|

metal case;plywood case;carton or as requirement |

|

Delivery time |

30days upon receipt of 30% deposit; or upon receipt of relevant L/C; |

- About us

We specialize in this line for more than 20 years and trader with main products as follows: hydraulic cylinders, hydraulic power units, hydraulic manifolds-blocks, hydraulic flanges,pneumatic cylinders and custom-made components and parts, like industrial valves.

Our sales markets have covered North America, Europe, Australia, Japan and ect.

- Working Process

- Packaging & shipping

- FAQ

Q1: Do you accept OEM manufacturing?

A1: Yes! We do accept OEM manufacturing. We will quote you the exact price and make the exact cylinder according to your specification and drawing.

Q2: Can we design our own package or print our own logo?

A2: Yes! Package and logo will be made acording to your requirements.

Q3: Could we get small quantity samples?

A3: Yes! We understand the quality test is important and we are glad to make the sample for you. The MOQ is 1pcs.

Q4: How long is the production time?

A4: Generally the production time is 30 days.

Q5: What is the warranty?

A5: 12 months against B/L date.

Contact me, any comments will be appreciated.

Ellen Wang

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Samples: |

US$ 59/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lift cylinders be used in aerial work platforms and scissor lifts?

Yes, lift cylinders are commonly used in aerial work platforms and scissor lifts. Here’s an explanation of their utilization in these types of equipment:

Aerial work platforms, also known as aerial lifts or elevated work platforms, are used to provide elevated access for various tasks, such as maintenance, construction, or inspection work. Scissor lifts are a specific type of aerial work platform that utilize a scissor mechanism to vertically extend the platform. Lift cylinders play a crucial role in the lifting operation of both aerial work platforms and scissor lifts.

In scissor lifts, multiple lift cylinders are typically positioned vertically and connected to the scissor mechanism. These lift cylinders work in synchronization to extend or retract the scissor arms, thereby raising or lowering the platform. The lift cylinders exert force to expand the scissor arms, creating a lifting motion that allows the platform to reach elevated positions. By controlling the flow of hydraulic fluid to the lift cylinders, operators can easily adjust the platform height and achieve the desired working elevation.

Lift cylinders used in aerial work platforms and scissor lifts are usually hydraulic cylinders. Hydraulic systems offer the advantages of smooth operation, precise control, and high lifting capacities. The hydraulic system includes a pump, control valves, hydraulic lines, and the lift cylinders. When the hydraulic system is activated, the pump pressurizes the hydraulic fluid, which is then directed to the lift cylinders through the control valves. The pressurized fluid causes the lift cylinders to extend, resulting in the upward movement of the platform.

One of the key benefits of using lift cylinders in aerial work platforms and scissor lifts is their ability to provide stable and controlled lifting. The synchronized movement of the lift cylinders ensures that the platform remains level and secure during the lifting process. This stability is essential for safe working conditions at elevated heights.

In addition to lifting capabilities, lift cylinders in aerial work platforms and scissor lifts may incorporate features such as safety locks, overload protection, or emergency descent mechanisms. These safety measures enhance the overall performance and reliability of the equipment, ensuring the well-being of operators working at height.

Overall, lift cylinders are integral components in aerial work platforms and scissor lifts, enabling the vertical lifting motion and providing stability during elevated work. Their hydraulic operation, synchronized movement, and safety features make them essential for efficient and secure access at height.

Can lift cylinders be used in agricultural machinery and equipment?

Yes, lift cylinders are commonly used in agricultural machinery and equipment. Here’s an explanation of their utilization in this context:

Agricultural machinery and equipment often require lifting capabilities to perform various tasks such as loading, lifting, and adjusting components. Lift cylinders provide the necessary force and control to accomplish these operations effectively.

1. Tractors and Loaders:

Lift cylinders are extensively used in agricultural tractors and loaders. These cylinders are typically integrated into the hydraulic systems of the equipment and are responsible for lifting and lowering front-end attachments, such as buckets, forks, or blades. By extending and retracting the lift cylinders, operators can control the height and position of the attachments, enabling efficient material handling, loading, and leveling tasks.

2. Harvesting and Threshing Equipment:

In harvesting and threshing equipment, lift cylinders are employed to adjust and control the height of components such as headers, cutter bars, or platforms. These cylinders enable operators to adapt to different crop heights and ground conditions, ensuring optimal harvesting performance. By utilizing lift cylinders, agricultural machinery can effectively navigate uneven terrain and maintain consistent cutting or harvesting heights.

3. Sprayers and Spreaders:

Lift cylinders are also utilized in agricultural sprayers and spreaders. These cylinders are responsible for raising and lowering the booms or spreading mechanisms. By adjusting the lift cylinders, operators can control the application height or spreading width, ensuring precise and uniform coverage of fertilizers, pesticides, or seeds.

4. Irrigation Systems:

In irrigation systems, lift cylinders are used to control the height and position of irrigation equipment such as sprinklers or pivots. These cylinders allow for efficient adjustment of the irrigation components to ensure optimal water distribution across agricultural fields.

5. Implements and Attachments:

Lift cylinders are widely employed in various agricultural implements and attachments, including plows, harrows, cultivators, and seed drills. These cylinders facilitate the lifting and lowering of the implements, allowing for depth adjustments, ground clearance, and transport modes. Lift cylinders enhance the versatility and functionality of agricultural equipment, enabling farmers to efficiently perform a wide range of field operations.

In summary, lift cylinders have significant applications in agricultural machinery and equipment. They contribute to the lifting, lowering, and positioning tasks required for efficient material handling, leveling, harvesting, spreading, and irrigation operations. By utilizing lift cylinders, agricultural equipment becomes more versatile, productive, and adaptable to the specific needs of farmers and agricultural practices.

Can lift cylinders be used for both lifting and lowering applications?

Yes, lift cylinders are designed to be versatile and can be used for both lifting and lowering applications. Here’s an explanation of how lift cylinders are utilized for both lifting and lowering:

Lift cylinders are a type of hydraulic cylinder that converts fluid pressure into linear motion. They consist of a cylinder barrel, a piston, a rod, and seals. When hydraulic fluid is pressurized and directed into the cylinder, it exerts force on the piston, causing it to move in a linear direction.

Lifting Applications:

In lifting applications, the lift cylinder extends to raise or lift a load. As hydraulic fluid is pumped into the cylinder, the pressure increases, pushing the piston and rod outward. This extension of the cylinder generates the necessary force to lift the load. The lifting capacity of the cylinder depends on its design, including the diameter of the piston and the pressure rating of the system.

Lowering Applications:

For lowering applications, the lift cylinder retracts to lower the load. By controlling the flow of hydraulic fluid out of the cylinder, the pressure is reduced, allowing the weight of the load to push the piston and rod back into the cylinder. This controlled retraction enables smooth and controlled lowering of the load.

Lift cylinders are commonly used in various industries and applications where controlled vertical motion is required. Examples include lifting platforms, scissor lifts, dump trucks, hydraulic elevators, and material handling equipment. The ability to perform both lifting and lowering actions makes lift cylinders highly versatile and adaptable to different operational needs.

In summary, lift cylinders can be utilized for both lifting and lowering applications. By controlling the flow of hydraulic fluid, these cylinders can extend to lift a load and retract to lower it, offering flexibility and efficiency in a wide range of industries and equipment.

editor by CX 2023-11-29

China factory Gas Cylinder Hydraulic Lift Gas for Tailgates 430mm Extend vacuum pump connector

Product Description

| Name | Standard Gas Spring |

| Use | Automobile, Toolbox, Car, Furniture, Machines, Mechanical Equipment, Boat, Container etc. |

| Quality Standards | 1.180,000 times -passed fatigue test |

| 2.ROHS certificated by SGS | |

| 3.Passed ISO9001 Quality System Certification | |

| Material | Steel |

| Stainless Steel 304 | |

| Stainless Steel 316 | |

| endfittings | ball connector/metal eye/clevis and so on |

| Advantages | 1. Pass 180,000 Times Fatigue Times |

| 2.Up to 36hours salt spray test | |

| 3. 3-5 years product warranty | |

| 4. Fast Delivery Time: 1000 pcs 3 Days | |

| 5. Free Sample avaiable | |

| Trade Term | FOB ZheJiang or C&F price if you need |

| Gas Spring Parameter | |||

| Piston Dia | Tube Dia | Stroke(max) | F1 |

| mm | mm | mm | N |

| 6 | 15 | 150 | 50-400 |

| 8 | 18 | 250 | 50-600 |

| 10 | 22 | 400 | 100-1150 |

| 12 | 25 | 450 | 100-1600 |

| 14 | 28 | 500 | 500-2100 |

FAQ

Cathy: Are you factory?

JR: Yes,We are a manufacturer factory. We have plant area There Thousand square meters, and we are keeping extending our plant.We have about 10-20employees in different departments.

Customer: What is your price terms?

JR:Normally FOB(free on board) , CIF(cost insurance and freight)

Customer: What is your payment terms?

JR :Generally T/T 30% deposit, the balance should be paid by T/T before shipment .

Customer: How can I visit your factory or office?

JR:Welcome you visit our factory or office for business negotiation. Please try to contact our staff first by email or telephone. We will make the soonest appointment and arrangement the pick up.

Customer: Can you produce the goods as customer design?

JR :Welcome you send us the design or sample, we will calculated the cost and unit price to you in soonest.

Customer: May I get your sample for free?

JR :Sure, you will get our free sample. But the freight should be paid under your freight collected account in the first cooperation.

Customer: How about the products packing?

JR:Packing as the different products and different sizes, we have professional export design packing for our customer, and we could as customer required.

| Length: | Can Be Customed |

|---|---|

| Salt Spray Test: | up to 48 Hours |

| Force: | Can Be Customed |

| Package: | 50PCS/Carton |

| Piston Rod Material: | Qpq |

| Material: | Paint Steel/ Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does a lift cylinder contribute to stable and safe lifting operations?

A lift cylinder plays a crucial role in ensuring stable and safe lifting operations. Here’s an explanation of how a lift cylinder contributes to stability and safety:

1. Load Capacity and Stability:

A lift cylinder is designed to handle specific load capacities, and this capacity directly affects the stability of the lifting operation. The cylinder’s load rating ensures that it can safely support and lift the intended load without compromising stability. By selecting a lift cylinder with an appropriate load capacity, operators can ensure that the weight of the load is well-distributed and controlled, minimizing the risk of tip-overs or excessive swaying during lifting.

2. Controlled Lifting Speed:

Lift cylinders provide the ability to control the lifting speed, contributing to stable and safe operations. By regulating the hydraulic flow rate, operators can adjust the speed at which the cylinder extends or retracts. This controlled lifting speed allows for precise positioning of the load and reduces the potential for sudden shifts or jerky movements that could compromise stability or cause accidents.

3. Positioning Accuracy:

Lift cylinders offer precise positioning capabilities, ensuring that the load is raised, lowered, or held at the desired height accurately. This accurate positioning is crucial in maintaining stability and preventing unintended movements. Whether it’s aligning the load with a specific docking point or achieving precise height adjustments, lift cylinders allow for controlled and stable positioning.

4. Safety Mechanisms:

Lift cylinders often incorporate safety mechanisms to enhance safe lifting operations. These mechanisms can include features such as overload protection, emergency stop functions, or velocity fuses. Overload protection prevents the cylinder from attempting to lift loads beyond its capacity, while emergency stop functions allow for immediate cessation of lifting operations in case of emergencies. Velocity fuses are safety devices that prevent uncontrolled descent of the load in the event of a hydraulic system failure, ensuring stability and preventing accidents.

5. Durability and Reliability:

Lift cylinders are built to withstand demanding operational conditions and provide long-term durability and reliability. They are constructed with robust materials and incorporate seals, bearings, and other components to ensure smooth operation and prevent leaks or failures. The durability and reliability of lift cylinders contribute to stable lifting operations by minimizing the risk of unexpected malfunctions or breakdowns.

In summary, lift cylinders contribute to stable and safe lifting operations through their load capacity and stability, controlled lifting speed, precise positioning accuracy, incorporation of safety mechanisms, and overall durability and reliability. These features ensure that lifting operations can be carried out smoothly, efficiently, and with a reduced risk of accidents or instability.

Can lift cylinders be used in agricultural machinery and equipment?

Yes, lift cylinders are commonly used in agricultural machinery and equipment. Here’s an explanation of their utilization in this context:

Agricultural machinery and equipment often require lifting capabilities to perform various tasks such as loading, lifting, and adjusting components. Lift cylinders provide the necessary force and control to accomplish these operations effectively.

1. Tractors and Loaders:

Lift cylinders are extensively used in agricultural tractors and loaders. These cylinders are typically integrated into the hydraulic systems of the equipment and are responsible for lifting and lowering front-end attachments, such as buckets, forks, or blades. By extending and retracting the lift cylinders, operators can control the height and position of the attachments, enabling efficient material handling, loading, and leveling tasks.

2. Harvesting and Threshing Equipment:

In harvesting and threshing equipment, lift cylinders are employed to adjust and control the height of components such as headers, cutter bars, or platforms. These cylinders enable operators to adapt to different crop heights and ground conditions, ensuring optimal harvesting performance. By utilizing lift cylinders, agricultural machinery can effectively navigate uneven terrain and maintain consistent cutting or harvesting heights.

3. Sprayers and Spreaders:

Lift cylinders are also utilized in agricultural sprayers and spreaders. These cylinders are responsible for raising and lowering the booms or spreading mechanisms. By adjusting the lift cylinders, operators can control the application height or spreading width, ensuring precise and uniform coverage of fertilizers, pesticides, or seeds.

4. Irrigation Systems:

In irrigation systems, lift cylinders are used to control the height and position of irrigation equipment such as sprinklers or pivots. These cylinders allow for efficient adjustment of the irrigation components to ensure optimal water distribution across agricultural fields.

5. Implements and Attachments:

Lift cylinders are widely employed in various agricultural implements and attachments, including plows, harrows, cultivators, and seed drills. These cylinders facilitate the lifting and lowering of the implements, allowing for depth adjustments, ground clearance, and transport modes. Lift cylinders enhance the versatility and functionality of agricultural equipment, enabling farmers to efficiently perform a wide range of field operations.

In summary, lift cylinders have significant applications in agricultural machinery and equipment. They contribute to the lifting, lowering, and positioning tasks required for efficient material handling, leveling, harvesting, spreading, and irrigation operations. By utilizing lift cylinders, agricultural equipment becomes more versatile, productive, and adaptable to the specific needs of farmers and agricultural practices.

How does a lift cylinder handle variations in load weight and pressure?

A lift cylinder is designed to handle variations in load weight and pressure to ensure efficient and safe operation. Here’s an explanation of how a lift cylinder handles these variations:

1. Design Considerations:

Lift cylinders are designed with specific load capacities and pressure ratings in mind. The components, such as the cylinder barrel, piston, and seals, are selected and sized accordingly to handle the anticipated loads and pressures. The design factors in safety margins to accommodate variations in load weight and pressure within the specified operational limits.

2. Hydraulic System:

The hydraulic system that powers the lift cylinder plays a crucial role in handling variations in load weight and pressure. The system includes components such as pumps, valves, and control systems that regulate the flow and pressure of hydraulic fluid. By adjusting the system parameters, such as the pump output or valve settings, the hydraulic system can adapt to different load weights and pressure requirements.

3. Pressure Regulation:

Lift cylinders often incorporate pressure regulation mechanisms to handle variations in load weight and pressure. Pressure relief valves or pressure control valves are commonly used to maintain the desired pressure level within the cylinder. These valves ensure that the pressure does not exceed the specified limits, protecting the cylinder and other components from potential damage.

4. Balanced Design:

Lift cylinders are designed to achieve a balanced configuration that minimizes the impact of load weight variations. The placement of the piston and rod within the cylinder barrel is carefully engineered to distribute the load evenly and maintain stability. This balanced design helps to mitigate the effects of load weight changes on the cylinder’s performance and ensures smooth operation.

5. Control and Monitoring:

Advanced lift cylinder systems may incorporate control and monitoring features to handle variations in load weight and pressure more effectively. Sensors and feedback mechanisms can provide real-time data on load weight and cylinder performance, allowing the system to make adjustments as needed. This enhances the overall control and stability of the lift cylinder in response to changing conditions.

In summary, a lift cylinder handles variations in load weight and pressure through careful design considerations, hydraulic system adjustments, pressure regulation mechanisms, balanced configurations, and control and monitoring features. These aspects work together to ensure that the lift cylinder operates safely and efficiently, accommodating different load requirements while maintaining optimal performance.

editor by CX 2023-10-26