Product Description

Products Description

|

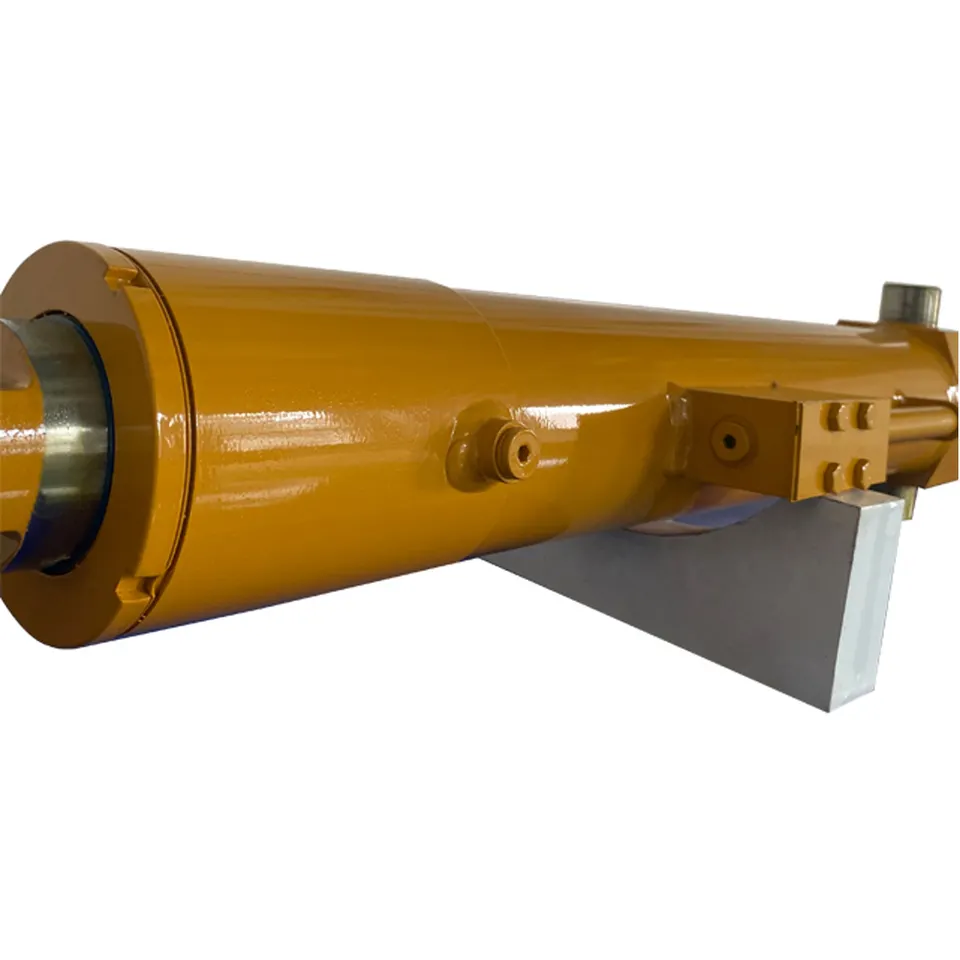

Product Name |

SYG Series Multi-Stage Hydraulic Cylinder |

|||

|

Work Press |

7/14/16/21/31.5MPa |

|||

|

Material |

Aluminum, Cast Iron,45mnb Steel, Stainless Steel |

|||

|

Stage |

Up to 6 stage |

|||

|

Bore Size |

40mm–320mm,Customizable |

|||

|

Shaft Diameter |

20mm–220mm,Customizable |

|||

|

Stroke Length |

30mm–14100mm,Customizable |

|||

|

Rod Surface Hardness |

HRC48-54 |

|||

|

Paint Color |

Black, Yellow, Blue, Brown, Customizable |

|||

|

Mounting |

Earring, Flange, Clevis.Foot, Trunnion, Customizable |

|||

|

Warranty |

1 Year |

|||

|

MOQ |

1 Piece |

|||

|

Delivery Time |

7-15 Days, Also depends on specific demands |

|||

|

Certification |

ISO9001, CE |

|||

Company Profile

QIANGLIN HYDRAULIC MACHINERY CO., LTD

| QiangLin is a professional hydraulic equipment manufacturer, mainly engaged in hydraulic system design, manufacture, installation, transformation, sales, and technical services. Our manufacturing facilities are certified to the ISO 9001 standard. We are an approved supplier to many equipment manufacturers in China. We are also partners with many customers from America, Canada, Australia, Germany, England, and other European Countries. Product quality, shorter delivery time, and customer satisfaction are our long-term commitments to our CHINAMFG customers. Hope to be your partner. |

FAQ:

Q1: Are you a trading company or a manufacturer?

A: We have our own factory.

Q2: Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, 15-30 working days if we don’t. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What are your After-sales services?

A: Before shipment, Each individual product will be strictly inspected on our factory QC Process

System. In addition, We have a

Customer Service team to respond to customers’ questions within 12 hours. Being helpful in

solving customers’ problems is always our goal. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a lift cylinder contribute to efficient and reliable lifting?

A lift cylinder plays a crucial role in enabling efficient and reliable lifting operations. Here’s an explanation of how a lift cylinder contributes to efficient and reliable lifting:

1. High Lifting Capacity:

Lift cylinders are specifically designed to provide high lifting capacities. They can generate substantial force to lift heavy loads, making them well-suited for material handling tasks that involve large or bulky items. The high lifting capacity ensures that the cylinder can effectively handle the intended load, contributing to efficient lifting without the need for additional equipment or manual labor.

2. Precise Control:

Lift cylinders offer precise control over the lifting process. By regulating the flow and pressure of hydraulic fluid, operators can achieve accurate positioning and controlled movements. This level of control allows for efficient and precise placement of the load, reducing the risk of damage to the load or surrounding objects. The precise control also enables operators to optimize the lifting process, saving time and effort.

3. Smooth and Stable Operation:

Lift cylinders provide smooth and stable operation during lifting operations. The hydraulic system ensures that the lifting motion is steady and controlled, minimizing jerking or sudden movements. This smooth operation is important for the safe handling of delicate or fragile materials. It also enhances operator confidence and reduces the risk of accidents, contributing to reliable lifting performance.

4. Quick Response Time:

Lift cylinders offer quick response times, allowing for efficient and timely lifting operations. When activated, the hydraulic system quickly directs fluid into the cylinder, initiating the lifting motion. This rapid response time reduces downtime and enables operators to complete lifting tasks more efficiently.

5. Durability and Reliability:

Lift cylinders are built to withstand the demands of heavy-duty lifting operations. They are constructed with durable materials and designed to handle repetitive lifting tasks over extended periods. The robust construction and reliable performance of lift cylinders ensure that they can consistently deliver efficient lifting performance without frequent breakdowns or malfunctions.

6. Safety Features:

Lift cylinders often incorporate safety features to enhance reliability during lifting operations. These features can include load-holding valves, pressure relief valves, and fail-safe mechanisms. Load-holding valves prevent the load from dropping in the event of hydraulic pressure loss, ensuring the load remains securely lifted. Pressure relief valves protect the system from excessive pressure, preventing potential damage. Fail-safe mechanisms provide additional safety by engaging in the event of a system failure or power loss. The presence of these safety features contributes to reliable and safe lifting operations.

7. Integration with Control Systems:

Advanced lift cylinders can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs). This integration allows for automation and optimized control of the lifting process. By incorporating sensors, feedback mechanisms, and pre-programmed sequences, the lift cylinder can operate efficiently and reliably with minimal operator intervention.

In summary, a lift cylinder contributes to efficient and reliable lifting through its high lifting capacity, precise control, smooth and stable operation, quick response time, durability and reliability, incorporation of safety features, and integration with control systems. These features and capabilities ensure that the lifting process is efficient, accurate, and safe, thereby enhancing overall lifting performance.

Can lift cylinders be used in agricultural machinery and equipment?

Yes, lift cylinders are commonly used in agricultural machinery and equipment. Here’s an explanation of their utilization in this context:

Agricultural machinery and equipment often require lifting capabilities to perform various tasks such as loading, lifting, and adjusting components. Lift cylinders provide the necessary force and control to accomplish these operations effectively.

1. Tractors and Loaders:

Lift cylinders are extensively used in agricultural tractors and loaders. These cylinders are typically integrated into the hydraulic systems of the equipment and are responsible for lifting and lowering front-end attachments, such as buckets, forks, or blades. By extending and retracting the lift cylinders, operators can control the height and position of the attachments, enabling efficient material handling, loading, and leveling tasks.

2. Harvesting and Threshing Equipment:

In harvesting and threshing equipment, lift cylinders are employed to adjust and control the height of components such as headers, cutter bars, or platforms. These cylinders enable operators to adapt to different crop heights and ground conditions, ensuring optimal harvesting performance. By utilizing lift cylinders, agricultural machinery can effectively navigate uneven terrain and maintain consistent cutting or harvesting heights.

3. Sprayers and Spreaders:

Lift cylinders are also utilized in agricultural sprayers and spreaders. These cylinders are responsible for raising and lowering the booms or spreading mechanisms. By adjusting the lift cylinders, operators can control the application height or spreading width, ensuring precise and uniform coverage of fertilizers, pesticides, or seeds.

4. Irrigation Systems:

In irrigation systems, lift cylinders are used to control the height and position of irrigation equipment such as sprinklers or pivots. These cylinders allow for efficient adjustment of the irrigation components to ensure optimal water distribution across agricultural fields.

5. Implements and Attachments:

Lift cylinders are widely employed in various agricultural implements and attachments, including plows, harrows, cultivators, and seed drills. These cylinders facilitate the lifting and lowering of the implements, allowing for depth adjustments, ground clearance, and transport modes. Lift cylinders enhance the versatility and functionality of agricultural equipment, enabling farmers to efficiently perform a wide range of field operations.

In summary, lift cylinders have significant applications in agricultural machinery and equipment. They contribute to the lifting, lowering, and positioning tasks required for efficient material handling, leveling, harvesting, spreading, and irrigation operations. By utilizing lift cylinders, agricultural equipment becomes more versatile, productive, and adaptable to the specific needs of farmers and agricultural practices.

Can lift cylinders be used for both lifting and lowering applications?

Yes, lift cylinders are designed to be versatile and can be used for both lifting and lowering applications. Here’s an explanation of how lift cylinders are utilized for both lifting and lowering:

Lift cylinders are a type of hydraulic cylinder that converts fluid pressure into linear motion. They consist of a cylinder barrel, a piston, a rod, and seals. When hydraulic fluid is pressurized and directed into the cylinder, it exerts force on the piston, causing it to move in a linear direction.

Lifting Applications:

In lifting applications, the lift cylinder extends to raise or lift a load. As hydraulic fluid is pumped into the cylinder, the pressure increases, pushing the piston and rod outward. This extension of the cylinder generates the necessary force to lift the load. The lifting capacity of the cylinder depends on its design, including the diameter of the piston and the pressure rating of the system.

Lowering Applications:

For lowering applications, the lift cylinder retracts to lower the load. By controlling the flow of hydraulic fluid out of the cylinder, the pressure is reduced, allowing the weight of the load to push the piston and rod back into the cylinder. This controlled retraction enables smooth and controlled lowering of the load.

Lift cylinders are commonly used in various industries and applications where controlled vertical motion is required. Examples include lifting platforms, scissor lifts, dump trucks, hydraulic elevators, and material handling equipment. The ability to perform both lifting and lowering actions makes lift cylinders highly versatile and adaptable to different operational needs.

In summary, lift cylinders can be utilized for both lifting and lowering applications. By controlling the flow of hydraulic fluid, these cylinders can extend to lift a load and retract to lower it, offering flexibility and efficiency in a wide range of industries and equipment.

editor by CX 2024-04-11