Product Description

Product Description

5Y

525710705 12530305 37222 WG951682-D979E 0571 1 WG971982 518553 518553 0571 525715711 ID-07208-CY DZ97259820128 50 0571 1-C03-D979E 14333857 15717 0571 1 525714305 41953 62571571 M1 0571 5016161 M571610304 518553 525710705 615553 936553 565714505 N0 0571 7106 6243 50A-5711 5-Q458 N0 0571 2 5 5 WG9925824014/1 0571 1 0571 1 CBPX-F1 M 106184 0161 0571 565713505 525710505 387553571

Our company specilize in dealing with all kinds of beiben heavy duty truck parts for NG80A,NG80B,V3,V3M,V3ET,V3MT,

from cab parts to chassis parts ,engine parts,gearbox parts,suspensiton parts,all kinds of engine mounting,bracket,leaf spring.We have factory to produce all kinds of alternator,starter,clutch plate,clutch cover,radiator,intercooler,can prodcue different size fuel tank according to customer requirement.

If you demand or are intersted in our products,please do not hesistate to contact with me,we will give best service with good quality and good price.Wish we can have long term copperation

Detailed Photos

MPANY SPEXIHU (WEST LAKE) DIS.ZE IN DEAL WITH ALL KINDS OF HEAY DUTY TRUCK PARTS? FOR BEIBEN

(ALSO NAMED NORTH-Benz TRUCK, BEIFANG Benz TRUCK), FROM EURO II MODEL TO EURO III,

NG80A, NG80B, V3, TO V3M ,V3ET MODEL BEIBEN TRUCK.

THE TRUCK PARTS COVER CABIN

PARTS, CHASSIS PARTS, ENGINE PARTS, GEARBOX PARTS, EXHAUST SYSTEM PARTS.

Packaging & Shipping

1. Packaging details: carton and wooden box packaging,woven bag,brown box, or

according to customer requirements.

2. Delivery Period: 7-30 working days after receiving 30% deposit byTT

3. Port: HangZhou Port,China.

4. Transport: By sea, by air,DHL,FEDEX,UPS,TNT,

FAQ

1.Q:About the payment term.

A: We can accept TT,LC,PAYPAL,WESTERNUION,and so on

2.Q:About the Quality and price

A: We supply good quality products to all our customers,give the competitive price.

3.Q:About the warranty period

A:At least half year, some parts are even longer.

4. Q:How to make order ?

A:Customer can contact us online,or send email with detail inquiry list,then we can reply soon

5.Q:About the discount

A:If the quantity large,we will give resonalbe discount.And for long time cooperation customer,we can give credit support

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Change for Quality Problem |

|---|---|

| Material: | Steel |

| Car Make: | Beiben |

| Position: | Rear |

| OEM: | No |

| Type: | Steering Column |

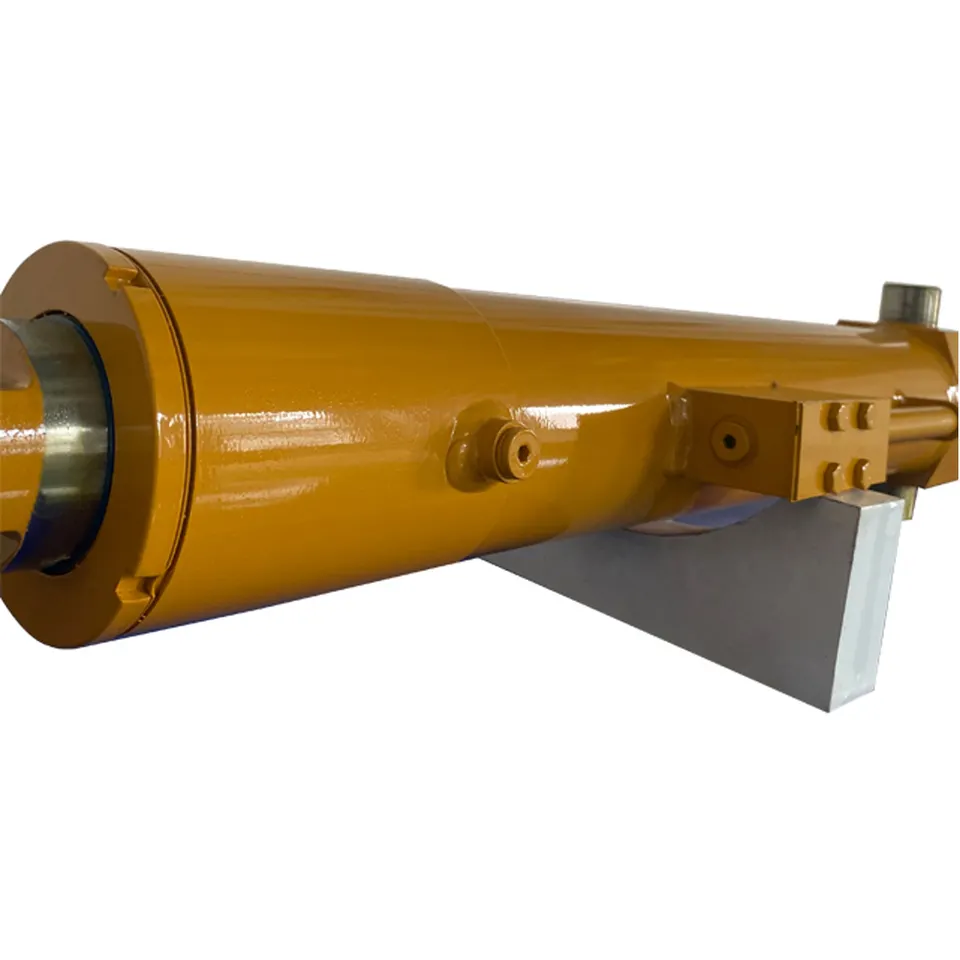

How does a lift cylinder contribute to efficient and reliable lifting?

A lift cylinder plays a crucial role in enabling efficient and reliable lifting operations. Here’s an explanation of how a lift cylinder contributes to efficient and reliable lifting:

1. High Lifting Capacity:

Lift cylinders are specifically designed to provide high lifting capacities. They can generate substantial force to lift heavy loads, making them well-suited for material handling tasks that involve large or bulky items. The high lifting capacity ensures that the cylinder can effectively handle the intended load, contributing to efficient lifting without the need for additional equipment or manual labor.

2. Precise Control:

Lift cylinders offer precise control over the lifting process. By regulating the flow and pressure of hydraulic fluid, operators can achieve accurate positioning and controlled movements. This level of control allows for efficient and precise placement of the load, reducing the risk of damage to the load or surrounding objects. The precise control also enables operators to optimize the lifting process, saving time and effort.

3. Smooth and Stable Operation:

Lift cylinders provide smooth and stable operation during lifting operations. The hydraulic system ensures that the lifting motion is steady and controlled, minimizing jerking or sudden movements. This smooth operation is important for the safe handling of delicate or fragile materials. It also enhances operator confidence and reduces the risk of accidents, contributing to reliable lifting performance.

4. Quick Response Time:

Lift cylinders offer quick response times, allowing for efficient and timely lifting operations. When activated, the hydraulic system quickly directs fluid into the cylinder, initiating the lifting motion. This rapid response time reduces downtime and enables operators to complete lifting tasks more efficiently.

5. Durability and Reliability:

Lift cylinders are built to withstand the demands of heavy-duty lifting operations. They are constructed with durable materials and designed to handle repetitive lifting tasks over extended periods. The robust construction and reliable performance of lift cylinders ensure that they can consistently deliver efficient lifting performance without frequent breakdowns or malfunctions.

6. Safety Features:

Lift cylinders often incorporate safety features to enhance reliability during lifting operations. These features can include load-holding valves, pressure relief valves, and fail-safe mechanisms. Load-holding valves prevent the load from dropping in the event of hydraulic pressure loss, ensuring the load remains securely lifted. Pressure relief valves protect the system from excessive pressure, preventing potential damage. Fail-safe mechanisms provide additional safety by engaging in the event of a system failure or power loss. The presence of these safety features contributes to reliable and safe lifting operations.

7. Integration with Control Systems:

Advanced lift cylinders can be integrated with control systems, such as electronic controls or programmable logic controllers (PLCs). This integration allows for automation and optimized control of the lifting process. By incorporating sensors, feedback mechanisms, and pre-programmed sequences, the lift cylinder can operate efficiently and reliably with minimal operator intervention.

In summary, a lift cylinder contributes to efficient and reliable lifting through its high lifting capacity, precise control, smooth and stable operation, quick response time, durability and reliability, incorporation of safety features, and integration with control systems. These features and capabilities ensure that the lifting process is efficient, accurate, and safe, thereby enhancing overall lifting performance.

How Does a Lift Cylinder Contribute to Load Leveling and Distribution?

A lift cylinder plays a significant role in load leveling and distribution, ensuring stability and balanced weight distribution in various applications. Here’s a detailed explanation of how a lift cylinder contributes to load leveling and distribution:

- Vertical Force Generation:

- Multi-Cylinder Systems:

- Self-Leveling Mechanisms:

- Force Sensing and Control:

- Structural Support and Stability:

- Customization for Specific Applications:

When a lift cylinder is activated, it generates a vertical force that lifts or supports a load. The force exerted by the cylinder is directly proportional to its hydraulic or pneumatic pressure and the effective area of the piston. By adjusting the pressure or controlling the flow of fluid or gas into the cylinder, the force can be precisely regulated to achieve load leveling and distribution.

In applications where load leveling and distribution are critical, multiple lift cylinders may be used in a system. These cylinders work in synchronization to evenly distribute the load and maintain balance. By connecting the cylinders in parallel or series, the hydraulic or pneumatic pressure can be distributed across all cylinders, ensuring that each cylinder contributes proportionately to the load leveling and distribution process.

Some lift cylinder systems incorporate self-leveling mechanisms to automatically adjust the position and angle of the load. These mechanisms utilize sensors or feedback systems that monitor the load distribution and make real-time adjustments to the lift cylinders. If an imbalance or uneven weight distribution is detected, the self-leveling mechanisms activate the appropriate lift cylinders to counteract the imbalance and restore equilibrium. This contributes to load leveling and distribution, preventing excessive stress on specific areas or components.

Advanced lift cylinder systems may employ force sensing and control technologies to achieve precise load leveling and distribution. Force sensors are integrated into the lifting mechanism, allowing real-time monitoring of the forces exerted by the cylinders. This information is then used to adjust the hydraulic or pneumatic pressure, ensuring that each cylinder contributes optimally to the load distribution. By continuously monitoring and controlling the forces, the lift cylinder system can adapt to changing load conditions and maintain stable load leveling and distribution.

Lift cylinders provide structural support and stability to the load-bearing components in various applications. By evenly distributing the load, the cylinders help prevent excessive stress or strain on specific components. They ensure that the weight is evenly spread across the supporting structure, reducing the risk of structural damage or failure. Lift cylinders also contribute to the overall stability of the system, minimizing unwanted movements or vibrations caused by imbalanced loads.

Lift cylinders can be customized and tailored to specific applications to optimize load leveling and distribution. Factors such as cylinder size, stroke length, bore diameter, and material strength can be selected based on the load characteristics and weight distribution requirements of the particular application. By considering the specific needs of the application, lift cylinders can be designed and implemented to achieve the desired load leveling and distribution performance.

Overall, a lift cylinder is a crucial component in achieving load leveling and distribution in various applications. Whether through vertical force generation, multi-cylinder systems, self-leveling mechanisms, force sensing and control, structural support, or customization, lift cylinders contribute to maintaining stability, balance, and even weight distribution, ensuring optimal performance and safety in diverse industrial and mechanical systems.

What is a lift cylinder and how does it function in hydraulic systems?

A lift cylinder, also known as a hydraulic lift cylinder or hydraulic lifting cylinder, is a device used in hydraulic systems to generate linear motion and provide lifting force. It is a type of hydraulic actuator that converts hydraulic pressure into mechanical force to lift heavy loads. Here’s an explanation of what a lift cylinder is and how it functions in hydraulic systems:

A lift cylinder consists of a cylindrical barrel, a piston, and a rod. The barrel is a hollow tube that houses the piston and allows fluid to flow in and out. The piston is a cylindrical component that separates the barrel into two chambers. The rod, attached to the piston, extends from the cylinder to connect with the load or the mechanism being lifted.

The lift cylinder operates based on the principles of Pascal’s law, which states that pressure exerted on a fluid in a confined space is transmitted equally in all directions. Here’s how a lift cylinder functions:

1. Extension:

When pressurized hydraulic fluid enters one side of the cylinder (the chamber behind the piston), it applies force on the piston, causing it to move in the direction of the load. This movement extends the rod outward, lifting or pushing the load.

2. Retraction:

Conversely, when the hydraulic fluid is supplied to the other side of the cylinder (the chamber in front of the piston), the pressure differential causes the piston to move in the opposite direction. This retracts the rod, lowering or pulling the load.

3. Control Valve:

The flow of hydraulic fluid into and out of the lift cylinder is controlled by a directional control valve. The valve regulates the direction and amount of fluid entering the cylinder, determining whether the cylinder extends or retracts. This control allows for precise and controlled lifting and lowering of the load.

4. Force and Load Capacity:

The force generated by the lift cylinder is determined by the hydraulic pressure applied to the piston and the effective area of the piston. By increasing or decreasing the hydraulic pressure, the lifting force can be adjusted to meet the specific load requirements.

5. Application:

Lift cylinders are widely used in various hydraulic systems, including hydraulic lifts, cranes, forklifts, dump trucks, and construction equipment. They provide the necessary force to lift heavy objects, perform material handling tasks, and support heavy loads in a controlled and efficient manner.

In summary, a lift cylinder is a hydraulic actuator that converts hydraulic pressure into mechanical force for lifting heavy loads. It functions by utilizing hydraulic fluid pressure to move the piston and extend or retract the rod, enabling the lifting or lowering of the load. The control valve regulates the fluid flow, and the force generated by the lift cylinder is determined by the hydraulic pressure and piston area. Lift cylinders find extensive applications in hydraulic systems across various industries.

editor by CX 2024-03-26