Product Description

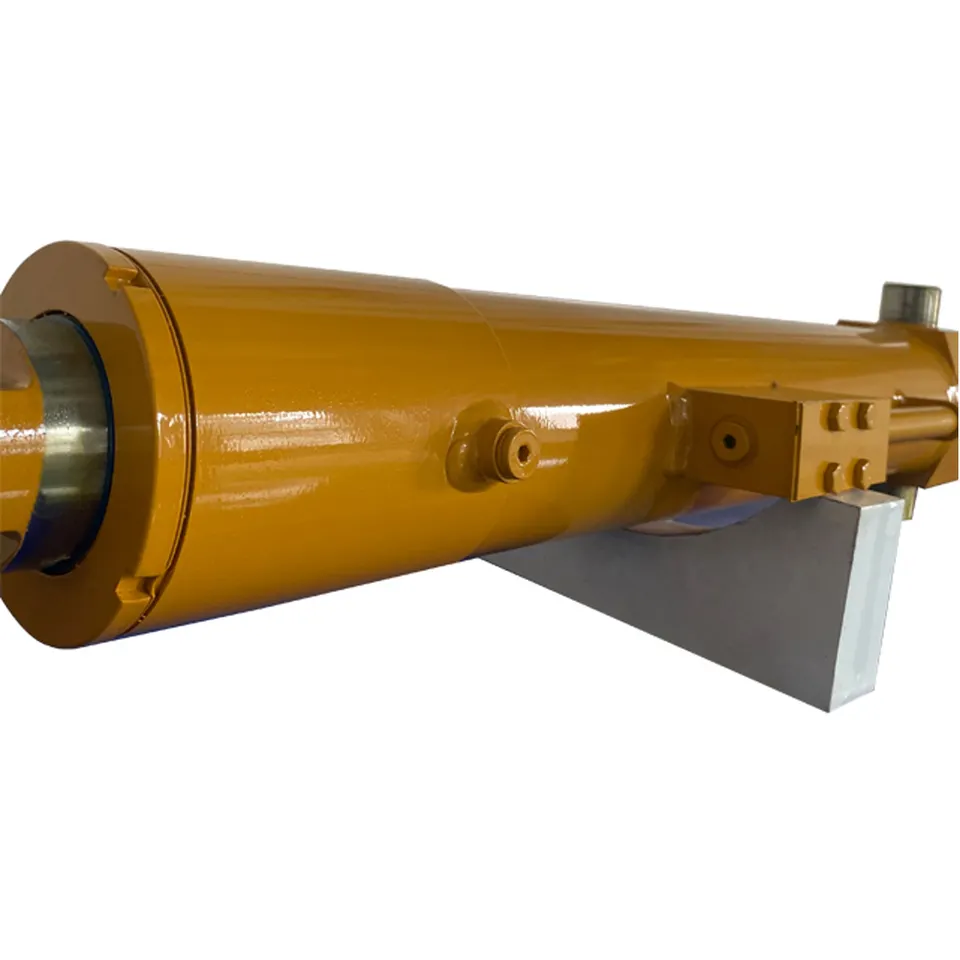

1.Product Picture

| Item | Underbody Hydraulic Cylinder |

| Application | Dump Truck&Trailer,Tipper,Dumper etc |

| HS CODE | 8412210090 |

| Each Stage Diameter(mm) | 214/191/169/149/129/110/91/75/60; 202/179/157/137/118/99/80/63; 221/196/172/150/129/110/91/75/60; |

| Max.Stroke(mm) | 2500mm |

| Max.Pressure(MPa) | 25MPa |

| Raw Matrial | Alloy Steel |

| Seal Kits | Hallite,Kaden,NOK,Guarnitec etc |

| Color | Black,Blue,Red,Gray,White etc |

| Package | Plywood Pallet,Steel Pallet etc suitable for export |

| Warranty | 14 months |

2.Company Introduction

Zhongxin Machinery specialize in the production and R&D of Dump Truck&Trailer Telescopic Hydraulic Cylinder,

Dump Truck Hydraulic System,Agricultural Machinery Hydraulic Cylinder, Garbage Truck Hydraulic Cylinder,

Tipping Platform Hydraulic Cylinder,Snow Plow Hydraulic Cylinder and so on.

Over the years development,our products have been exported to

America,Australia,Russia,Canada,Mexico,Guatemala,Colombia,Netherlands etc

and have been widely praised by the customers from home and abroad.

We are committed to providing customers with high quality and reasonable price products.

All ZhongXin products are designed,engineered and manufactured by highly skilled and experienced engineers,

All the products do QC 3 times before delivery to make sure the quality.

3.Product Introduction

4.Packing and Shipping

5.Custmoers

6.FAQ

A. Compared with CHINAMFG cylinder, what are your cylinder advantages?

1. Rod are chrome plated.

2. Tubes are quenched and tempered.

3.Tube inner hole goes through deep hole boring machine processing. Surface roughness is 0.4Ra

and circular degree is 0.571.

4. Good quality yet lower price.

B: Are you a manufacture or a trade company?

Manufacture, we are the leader manufacturer of hydraulic industry in China with 14 years’ experience and technology accumulation.

With strong technical team we could solve any annoyance of you.

C: How can I get a booklet and buy a cylinder from you?

Just leave me a message or email or call me directly, let me know you are interesting in our products. I will talk with you for the details soon!

1. Please advice the drawing with technical requirement.

2. Please advice the model No. after you check our booklet.

3. Please advice the tipping capacity, number of stages, closed length, mounting type and size.

4. Please also help advice the quantities, this is very important.

D: Do your products come with a warranty?

Yes, we have 14 months warranty. In this year, if the quality problem we will free repair for you.

E: What about the quality feedback of your products?

We have never received even once quality complaint for many years of international business.

F: Can you help me to install or recommend what kind of hydraulic cylinder or power pack should I use for specific machine?

Yes, we have 6 experienced engineers who are always ready to help you. If you do not know what kind of hydraulic cylinders should be used in your machine, please just contact us, our engineers will design the exact products match your need.

G: What is the delivery time?

Within 15 days for samples.

25-30 days for bulk production, which is depend on quality, production process and so on.

H: What is your main payment term?

T/T, L/C, either is available.

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | -30degrees-80degrees |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can lift cylinders be used in dock levelers and loading ramps?

Yes, lift cylinders can be used in dock levelers and loading ramps. Here’s an explanation of their utilization in these applications:

Dock levelers and loading ramps are essential equipment in logistics and transportation facilities, allowing for efficient loading and unloading of goods between trucks and loading docks. Lift cylinders play a crucial role in these systems by providing the necessary lifting and positioning capabilities.

In dock levelers, lift cylinders are employed to bridge the gap between the loading dock and the truck bed, ensuring a smooth transition for material handling equipment such as forklifts or pallet jacks. These cylinders are typically integrated into the mechanical or hydraulic systems of the dock leveler, allowing for controlled vertical movement. By extending or retracting the lift cylinders, the dock leveler can be adjusted to match the height of the truck bed, enabling safe and efficient loading or unloading of cargo.

Loading ramps, also known as mobile yard ramps or portable ramps, are used in situations where a permanent loading dock is not available or when additional flexibility is required. Lift cylinders are utilized in loading ramps to provide the means for height adjustment and inclination control. By extending or retracting the lift cylinders, the ramp can be raised or lowered to align with the truck bed height, facilitating the movement of goods between the ramp and the truck.

The use of lift cylinders in dock levelers and loading ramps ensures precise and controlled positioning during the loading and unloading process. Operators can adjust the lift cylinders to match the specific height requirements, allowing for smooth and safe transfer of materials without causing damage to the goods or the equipment.

Lift cylinders used in dock levelers and loading ramps are designed to withstand heavy loads and endure frequent use. They are constructed with robust materials and incorporate features such as seals and bearings to ensure durability and reliability in demanding industrial environments.

Furthermore, lift cylinders in dock levelers and loading ramps may incorporate safety features such as automatic descent control or velocity fuses. These safety mechanisms help prevent sudden drops or uncontrolled movements in the event of a hydraulic system failure, enhancing the overall safety of the loading and unloading operations.

In summary, lift cylinders are commonly utilized in dock levelers and loading ramps to provide reliable and controlled lifting and positioning capabilities. Their ability to handle heavy loads, facilitate height adjustment, and incorporate safety features makes them integral components in these applications, contributing to efficient and safe material handling operations.

Can lift cylinders be used in construction equipment like cranes?

Yes, lift cylinders are commonly used in construction equipment, including cranes. Here’s an explanation of their utilization in this context:

Lift cylinders play a crucial role in the lifting and positioning operations of construction equipment, providing the necessary force and control to handle heavy loads and perform various construction tasks.

1. Mobile Cranes:

Lift cylinders are integral components of mobile cranes, such as hydraulic truck cranes and rough terrain cranes. These cylinders are typically employed in the boom and jib systems of the crane. By extending or retracting the lift cylinders, the crane can raise or lower the boom or jib, allowing for vertical lifting and horizontal reach. Lift cylinders enable precise control over the crane’s lifting capacity, height, and reach, making them essential for safe and efficient construction operations.

2. Tower Cranes:

In tower cranes, lift cylinders are used to control the movement of the crane’s jib and counter-jib. These cylinders facilitate the horizontal slewing of the jib, allowing the crane to cover a wide range of working areas. By adjusting the lift cylinders, the crane operator can position the load at specific locations on the construction site, contributing to accurate and controlled material handling.

3. Crawler Cranes:

Crawler cranes, which are equipped with tracks for mobility, also utilize lift cylinders in their lifting systems. These cylinders enable the crane to raise and lower the boom, adjust the angle of the boom, and control the movement of the load. Lift cylinders in crawler cranes provide the necessary stability and lifting capacity to handle heavy loads in various construction scenarios.

4. Excavators and Backhoes:

Lift cylinders are commonly found in excavators and backhoes used in construction projects. These cylinders are employed to control the movement of the boom, stick, and bucket attachments. By extending or retracting the lift cylinders, operators can perform digging, lifting, and material handling tasks, enhancing the versatility and productivity of the equipment.

5. Other Construction Equipment:

Lift cylinders are also utilized in a wide range of other construction equipment, including concrete pumps, aerial work platforms, telescopic handlers, and articulated dump trucks. These cylinders provide the lifting and positioning capabilities required to perform specific construction tasks, such as concrete pouring, elevated work, material placement, and load handling.

In summary, lift cylinders are extensively used in construction equipment like cranes to enable safe and efficient lifting and positioning operations. Whether in mobile cranes, tower cranes, crawler cranes, excavators, or other construction machinery, lift cylinders contribute to the control, stability, and versatility of the equipment, enhancing productivity and ensuring the successful execution of construction projects.

What industries commonly use lift cylinders in their applications?

Lift cylinders, also known as hydraulic lift cylinders or hydraulic lifting cylinders, find applications in various industries where lifting, lowering, and vertical motion are required. Here are some industries that commonly use lift cylinders:

1. Material Handling and Logistics:

Lift cylinders are extensively used in material handling and logistics industries. They are employed in equipment such as forklifts, pallet jacks, and reach trucks to lift and lower loads, enabling efficient movement and storage of goods in warehouses, distribution centers, and manufacturing facilities.

2. Construction and Heavy Machinery:

In the construction industry, lift cylinders are utilized in equipment such as cranes, excavators, loaders, and scissor lifts. They provide the necessary lifting force to handle heavy materials, perform lifting operations at construction sites, and facilitate the movement of equipment and materials in challenging environments.

3. Automotive and Transportation:

In the automotive and transportation sectors, lift cylinders are used in applications such as vehicle lifts, car hoists, and hydraulic ramps. These cylinders enable the lifting and lowering of vehicles for maintenance, repair, and inspection purposes, ensuring efficient and safe operations in automotive workshops, garages, and service stations.

4. Aerospace and Aviation:

Lift cylinders play a critical role in the aerospace and aviation industries. They are employed in aircraft maintenance lifts, ground support equipment, and hydraulic systems for aircraft doors and landing gear. Lift cylinders enable the precise positioning and movement of aircraft components, ensuring safe and reliable operations in the aviation sector.

5. Manufacturing and Industrial Equipment:

In manufacturing and industrial settings, lift cylinders are utilized in a wide range of applications. They are used in hydraulic presses, machine tools, assembly lines, and industrial lifts to provide the necessary vertical motion for lifting, positioning, and manipulating various components and materials in production processes.

6. Healthcare and Medical Equipment:

Lift cylinders find applications in the healthcare industry, particularly in medical equipment such as patient lifts, hospital beds, and examination tables. These cylinders enable safe patient handling and positioning, facilitating caregiver tasks and ensuring patient comfort and mobility.

These are just a few examples of industries that commonly use lift cylinders in their applications. The versatility and reliability of lift cylinders make them valuable components in numerous sectors where controlled vertical motion and lifting capabilities are essential.

editor by CX 2023-12-08