Product Description

ECAS-250H Motorized Vehicle for High-Place Works Platform Orchard Platform

Product Description

Feature and Performance

-One charge (3-4 days of use) is suitable for handling and high-altitude use.

-Equipment can also be used on rainy days.

-Rated loading capacity 800 kg 33 control boxes (maximum working height (39 meters) when loading in 3 stages)

-Load case cover function Ramp level function.

Product Parameters

Major Specification:

| Item | Description |

Item |

Description

|

| Name of Machine |

Aerial Lift Truck | Weight of Vehicle (Weight) |

1540kg |

| Type |

ECAS-250H | Max Load(kg) | 800kg |

| Dimension(LengthxWidthxHeight) |

2880x1480x1440mm | Running Method | Infinite Track Type(Driven by a motor ) |

| Upon extension of the extended table(mm) |

3200mm | A driving motor Type | 48V 2KW |

| Max.ascending height(mm) |

2500mm | An illumination type | A lever type (a Joystick) |

| The height up to working table CHINAMFG max descending (mm) |

8mm | Running Speed(Km/h) | 3.5km/h |

| A horizontal angle of the left ,right and the front |

10° |

Type of Hydraulic Device | Hydraulic Power Pack (The highest oil pressure 15MPa) |

It is possible to extend the working table so that a work can be done up to 8m of the span length.

With the divided 4 sections, it is possible to extend them respectively according to worker’s convenience.

Detailed Photos

1. Energy saving and environmental protection.

2. Flexible operation.

3. Easy access to the orchard.

4. Crawler-type walking runs smoothly

Application scenarios

Product Action:

1. As you can see, this model can help you pick fruit in bulk and complete efficient picking operations. Such wheeled transportation can only be widely supported by most fruit farmers if it has the characteristics of convenient operation, lightness and flexibility, safe running speed, and certain overload capacity.

2.At the same time, it can help you prune fruit trees, remove redundant branches, ensure the light of the main pole, so that the branches can grow outward, and supervise the growth status of fruit trees.

Applicable scenarios: Industry / Agriculture / Household

Picking fruits and vegetables/House maintenance or construction/Warehouse/Outdoor and so on.

Exhibiting pictures

Package and Delivery

One charge, 5-6 days of use Wireless remote control (for upper and lower computers) Motors, chargers (self-produced semi-permanent) improve safety through ground design Electronic diagnostic instrument (no fault, upgrade)

Company Profile

ZheJiang CHINAMFG Autopats Co., Ltd. We are mainly engaged in the production of forklifts, electric handling equipment, and golf cart accessories, and are committed to the production and sales of agricultural machinery, with 17 years of industry experience.

FAQ

Q1.Can I have a sample order?

A: Yes, we welcome sample orders to test and check quality.

Q2. Do you have any MOQ limit?

A: Small quantity is accepted, but we offer a quantity discount.

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx, or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping are also optional.

Q4. What does after-sales look like?

A: We support 1 year of after-sales service.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production and confirm the design first based on our sample.

Q7. Does it support changing data?

A: Yes. Please send the data you want, and we will send you the video after debugging and send it to you after confirmation.

Q8. How to transport? Will it be damaged?

A: We provide shelf fixation and protection, to ensure product integrity.

| After-sales Service: | Online |

|---|---|

| Type: | Vertical Cut Harvester |

| Application: | Fruit |

| Samples: |

US$ 22000/Piece

1 Piece(Min.Order) | Order Sample Table lift Red 1 pc

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lift cylinders be used in aerial work platforms and scissor lifts?

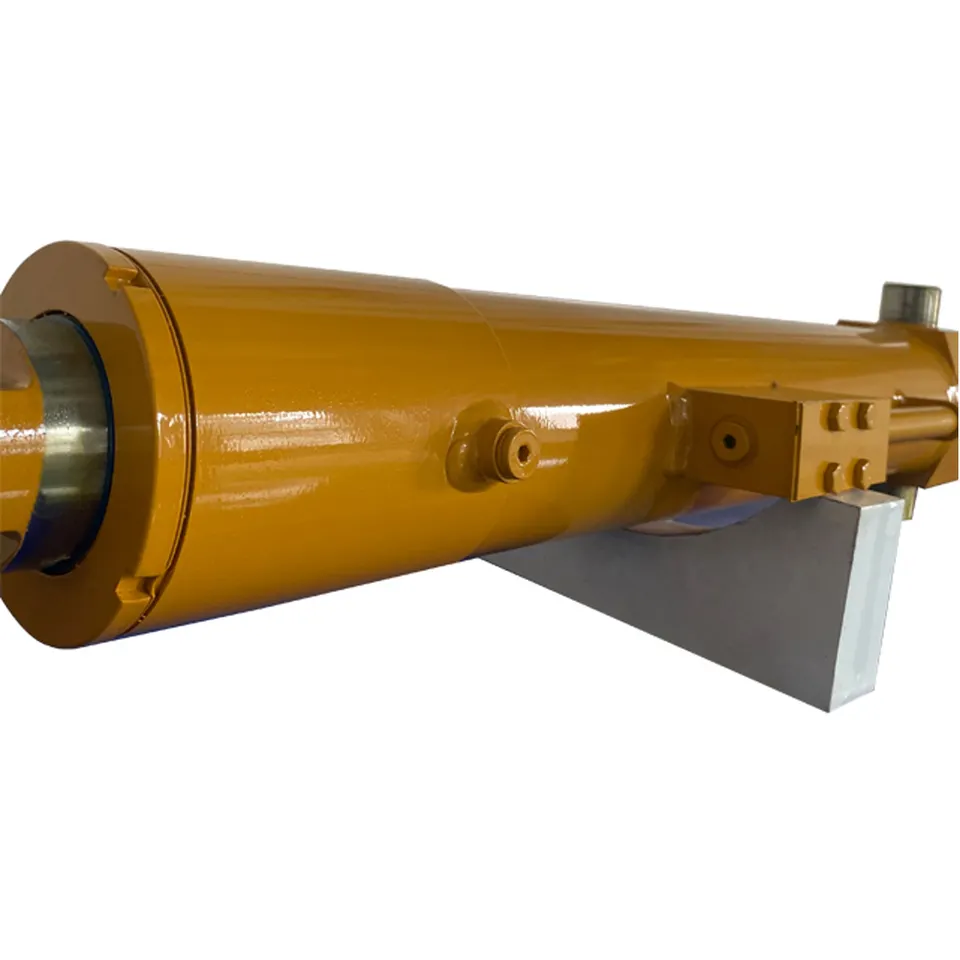

Yes, lift cylinders are commonly used in aerial work platforms and scissor lifts. Here’s an explanation of their utilization in these types of equipment:

Aerial work platforms, also known as aerial lifts or elevated work platforms, are used to provide elevated access for various tasks, such as maintenance, construction, or inspection work. Scissor lifts are a specific type of aerial work platform that utilize a scissor mechanism to vertically extend the platform. Lift cylinders play a crucial role in the lifting operation of both aerial work platforms and scissor lifts.

In scissor lifts, multiple lift cylinders are typically positioned vertically and connected to the scissor mechanism. These lift cylinders work in synchronization to extend or retract the scissor arms, thereby raising or lowering the platform. The lift cylinders exert force to expand the scissor arms, creating a lifting motion that allows the platform to reach elevated positions. By controlling the flow of hydraulic fluid to the lift cylinders, operators can easily adjust the platform height and achieve the desired working elevation.

Lift cylinders used in aerial work platforms and scissor lifts are usually hydraulic cylinders. Hydraulic systems offer the advantages of smooth operation, precise control, and high lifting capacities. The hydraulic system includes a pump, control valves, hydraulic lines, and the lift cylinders. When the hydraulic system is activated, the pump pressurizes the hydraulic fluid, which is then directed to the lift cylinders through the control valves. The pressurized fluid causes the lift cylinders to extend, resulting in the upward movement of the platform.

One of the key benefits of using lift cylinders in aerial work platforms and scissor lifts is their ability to provide stable and controlled lifting. The synchronized movement of the lift cylinders ensures that the platform remains level and secure during the lifting process. This stability is essential for safe working conditions at elevated heights.

In addition to lifting capabilities, lift cylinders in aerial work platforms and scissor lifts may incorporate features such as safety locks, overload protection, or emergency descent mechanisms. These safety measures enhance the overall performance and reliability of the equipment, ensuring the well-being of operators working at height.

Overall, lift cylinders are integral components in aerial work platforms and scissor lifts, enabling the vertical lifting motion and providing stability during elevated work. Their hydraulic operation, synchronized movement, and safety features make them essential for efficient and secure access at height.

How does a lift cylinder handle variations in cylinder stroke length?

A lift cylinder is designed to handle variations in cylinder stroke length through its adjustable rod or piston. The stroke length refers to the distance the cylinder can extend or retract, and it can be adjusted to meet specific requirements in different applications.

In hydraulic lift cylinders, the stroke length can be modified by adjusting the position of the rod or piston within the cylinder. This adjustment is typically achieved by adding or removing spacers or by using adjustable stops. By changing the effective length of the cylinder, the stroke can be increased or decreased accordingly.

The adjustment of the stroke length allows the lift cylinder to accommodate different operational needs. For example, in material handling applications, where varying load sizes are encountered, the stroke length can be adjusted to ensure that the cylinder extends or retracts precisely to the required position. This flexibility enables the lift cylinder to handle a wide range of loads and adapt to different lifting or pushing scenarios.

In addition to adjusting the stroke length, lift cylinders often incorporate position feedback mechanisms. These mechanisms, such as linear transducers or position sensors, provide real-time feedback on the actual position of the cylinder. By monitoring the position, the control system can ensure accurate and precise control over the cylinder’s movement, regardless of the stroke length.

The ability to handle variations in cylinder stroke length is crucial in many industrial applications. It allows for adaptability, efficiency, and improved performance in tasks such as material handling, assembly, and automation. By adjusting the stroke length, lift cylinders can optimize their operation, ensuring that the required force and movement are achieved consistently.

In summary, lift cylinders handle variations in cylinder stroke length through adjustable rods or pistons. This adjustment capability, combined with position feedback mechanisms, enables precise control and adaptability in different applications. By accommodating different stroke lengths, lift cylinders can effectively meet the specific requirements of a wide range of industrial tasks.

Can lift cylinders be repaired or replaced when damaged?

Yes, lift cylinders can be repaired or replaced when they are damaged. Here’s an explanation of the options for repairing or replacing lift cylinders:

1. Repair:

If a lift cylinder sustains damage, it is often possible to repair it. The extent of the damage and the specific components affected will determine the repair process. Common repairs may involve replacing seals, gaskets, or damaged hydraulic lines. In some cases, the cylinder may need to be disassembled, cleaned, and reassembled with new parts.

Repairing a lift cylinder typically requires expertise in hydraulic systems and cylinder repair. It is recommended to consult qualified professionals or authorized service centers to ensure proper diagnosis and repair procedures.

2. Replacement of Components:

If specific components within the lift cylinder are damaged or worn out, it may be possible to replace those components individually. This can include replacing the piston, rod, seals, or other internal parts. By replacing only the affected components, the cylinder can be restored to proper working condition without replacing the entire unit.

Replacement of components should be done with compatible parts that meet the manufacturer’s specifications. It may be necessary to consult the manufacturer’s documentation or seek guidance from authorized distributors or service centers to ensure proper component selection and installation.

3. Replacement of the Entire Cylinder:

In cases where the lift cylinder is severely damaged or if repairing or replacing individual components is not practical or cost-effective, it may be necessary to replace the entire cylinder. This involves removing the damaged cylinder and installing a new one that matches the specifications and requirements of the lifting equipment.

When replacing the entire cylinder, it is important to ensure compatibility with the equipment, including load capacity, mounting options, stroke length, and other specifications. The new cylinder should be selected based on the equipment’s requirements and the recommendations of the manufacturer or qualified experts.

4. Professional Assistance:

Repairing or replacing lift cylinders can be complex, especially when dealing with hydraulic systems and precise components. It is recommended to seek professional assistance from qualified technicians or authorized service centers. They have the knowledge, experience, and tools to properly diagnose, repair, or replace lift cylinders, ensuring the safety and optimal performance of the lifting equipment.

In summary, lift cylinders can be repaired or replaced when damaged. Repair options may involve replacing seals or damaged components, while component replacement allows for targeted repairs. In severe cases or when individual repairs are not feasible, the entire cylinder may need to be replaced. Professional assistance is recommended to ensure proper diagnosis, repair procedures, or component selection for the repair or replacement of lift cylinders.

editor by CX 2023-10-22