Product Description

Product Description

We(HangZhou BST) export construction machinery parts, specializes in the manufacturing and supplying of Shantui, Cat and komat su parts for over 15 years. Our company has a complete range such as engine parts ,transmission parts,hydraulic parts, electrical parts,drive parts,undercarriage parts, filter. Models such as komats D60/80/155,PC200/220/360 CAT D6/D7/D8/320/330 ect. The company provides high quality bulldozer parts and excavator parts that are designed to meet international standards. All of our products have undergone strict quality control protocols to ensure they maintain the highest standards.

Our advantage lies in:High-quality products, Competitive prices, Timely transaction and Professional service.

We are suppliers and manufacturer for Komat su, Caterpill ar shantui and parts in china

1. Excavator Parts:PC60, PC200, PC210, PC220, PC270, PC300, PC360, PC400, PC650,

PC750, PC850, PC1250

2. Loader Parts :WA320/WA380/WA420/WA460

3.Dozer Parts:D31, D41, D50, D60, D65, D80, D85, D155, D355, D375, D475

4.All models CHINAMFG bulldozer from 80hp-520hp: CHINAMFG SD13 SD16 SD22 SD23 SD32 TY160 TY220 TY230 TY320 bulldozer parts,etc

All CHINAMFG excavator: CHINAMFG SE60 SE130 SE210 SE220 SE240 SE330 SE360 excavator parts.

All CHINAMFG Road roller: SR12 SR14 SR16 SR18 SR20 SR22 SR26 road roller parts.

All CHINAMFG Motor grader : Shantui SG16 SG18 SG21 CHINAMFG Motor grader parts.

All CHINAMFG wheel loader: CHINAMFG SL20W SL30W SL50W SL60W CHINAMFG wheel loader parts.

5.Cumins Engine: 4B/4BT/6BT/NTA855/KTA13/KTA38/QSK19/QSK23/QSK45/QSK60 etc

6.CAT Excavtor:CAT320C/325C/330C/345C/320D/323D/324D/330D etc

7. CAT dozer: D5B, D5C, D5G, D6C, D6D, D6G, D6M, D6N, D6K, D6H, D6R, D7G, D7F, D7R, D7N,

D8N, D8L, D8R, D8K, D8T, D9G, D9H, D9N, D9R .D10R, D9T, D10T, D11T, D11R, D11 series

7.CHINAMFG Excavator: EC210B/240B/290B/360B/460B etc

8.Other: CHINAMFG forklift parts , CHINAMFG parts

708-1T-13310 piston sub ass’y

708-1T-13510 block ,cylinder

708-1S-13380 pin

708-1T-12420 bearing

706-73-4571 bearing

708-1T-13540 cuide ,retainer

708-1T-13550 reyeiner,shoe

ND094200-0400 Pump assy feed

6262-71-1110 Pump hight pressure

6745-31-2150 piston

6745-31-2140 pin

6742-01-5309 ring snap

6745-31-2571 piston ring ass’y

6743-31-3210 metal

6745-41-1110 camshaft ass’y

6742-01-5160 bushing

6745-41-2100 tappet ass’y

6745-41-4151 valve exhaust

6745-41-4520 collect

6745-11-1811 gasket head

6745-41-3100 rod

6745-11-7810 gasket

6732-21-1311 seal

6743-21-4190 gasket

6741-21-3810 gasket

6742-01- 0571 seal

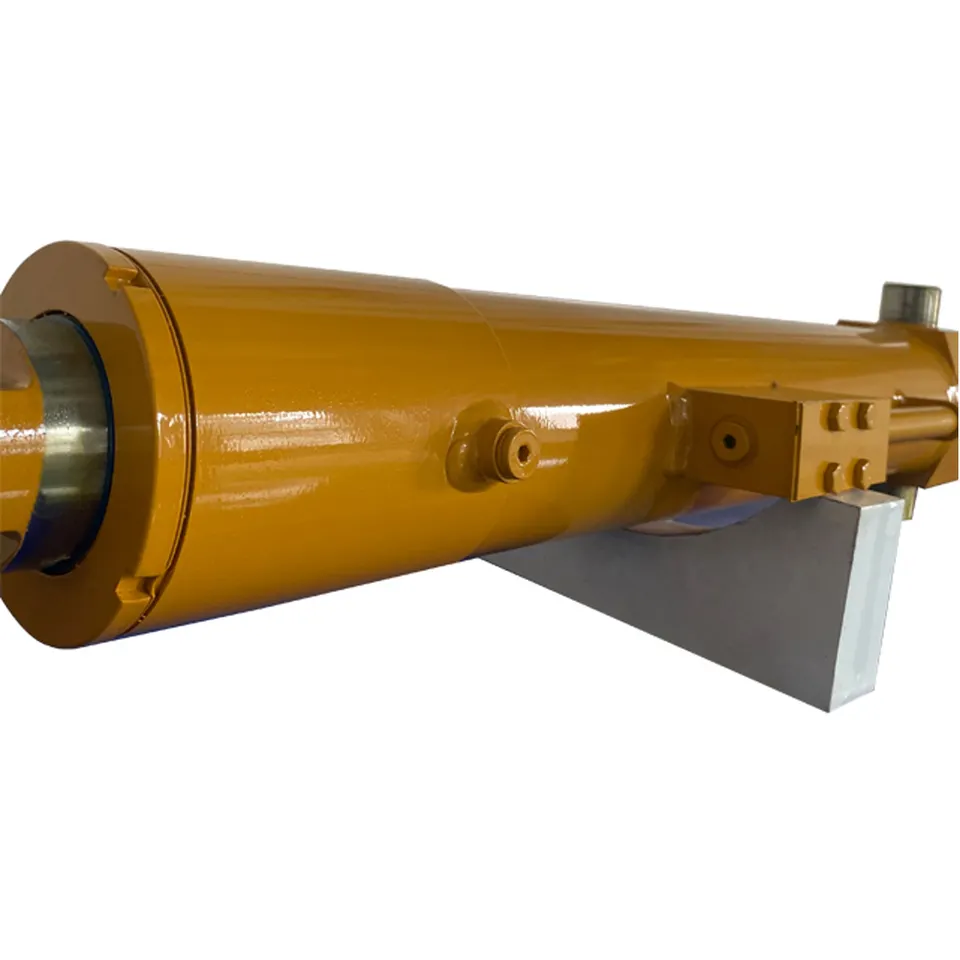

Lift Cylinder Ass’y 14Y-63-57116 for komat su D65P D60P-12 D85ESS-2

| Product Description | |

| Part No. | 14y-63-57116 |

| Part Name |

lift cylinder |

| warranty | 1 year |

| delivery time | 3-5 days |

| package | wooden case |

| MOQ | 1 piece |

| delivery way | By express/Air/Sea,as your needs |

FAQ

Q1:You are a trader or manufacturer .

We are a trader .

Q2: How about the payment terms ?

We usually accept T/T . Other terms also could be negotiated .

Q3: Warranty

3-6 months warranty. If any parts break during the warranty, Just offer us the proof . We’ll send you a new 1 !

Q5:If parts be lost during delivery , how solve ?

We’ll resend the parts free of charge .

Contact person: Monica

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Type: | Crawler |

| Application: | Bulldozer & Excavator |

| Certification: | ISO9001: 2000 |

| Condition: | New |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

What are the advantages of using lift cylinders in material handling?

Using lift cylinders in material handling offers several advantages that enhance efficiency, productivity, and safety. Here are some key advantages of using lift cylinders:

1. Lifting Capacity:

Lift cylinders are designed to provide substantial lifting capacity. They can handle heavy loads and are available in various sizes and configurations to accommodate different weight requirements. This allows for efficient lifting and moving of materials, reducing the need for manual labor or multiple lifting mechanisms.

2. Precise Control:

Lift cylinders offer precise control over the lifting and lowering operations. By regulating the flow and pressure of hydraulic fluid, operators can achieve accurate positioning and controlled movements. This level of control ensures safe and precise material handling, preventing damage to the load and the surrounding environment.

3. Smooth and Stable Operation:

Lift cylinders provide smooth and stable operation during lifting and lowering processes. The hydraulic system minimizes jerking or sudden movements, ensuring a controlled and stable lifting experience. This stability is crucial when handling fragile or delicate materials that require careful maneuvering.

4. Flexibility:

Lift cylinders offer flexibility in terms of their application and adaptability to different material handling scenarios. They can be integrated into various types of equipment, such as forklifts, cranes, or material handling platforms. This versatility allows for efficient material handling across different industries and environments.

5. Space Efficiency:

Compared to other lifting mechanisms, lift cylinders are relatively compact, which makes them suitable for applications where space is limited. The vertical movement of the cylinder allows for efficient use of vertical space, optimizing storage capacity and workspace utilization.

6. Durability and Longevity:

Lift cylinders are built to withstand rigorous and demanding material handling operations. They are constructed with sturdy materials and designed to withstand heavy loads, repetitive motions, and harsh working conditions. Proper maintenance and care can ensure their longevity, providing reliable performance over an extended period.

7. Safety:

Lift cylinders prioritize safety during material handling operations. They incorporate safety features such as pressure relief valves, load holding devices, and fail-safe mechanisms to prevent accidents or uncontrolled movements. These safety features help protect operators, bystanders, and the materials being lifted.

8. Reduced Manual Labor:

Using lift cylinders in material handling reduces the reliance on manual labor for lifting heavy loads. This improves productivity, reduces the risk of injuries associated with manual lifting, and allows operators to focus on other essential tasks, enhancing overall operational efficiency.

In summary, the advantages of using lift cylinders in material handling include high lifting capacity, precise control, smooth and stable operation, flexibility in application, space efficiency, durability, safety features, and reduced reliance on manual labor. These advantages contribute to improved efficiency, productivity, and safety in material handling operations.

How does a lift cylinder handle variations in cylinder stroke length?

A lift cylinder is designed to handle variations in cylinder stroke length through its adjustable rod or piston. The stroke length refers to the distance the cylinder can extend or retract, and it can be adjusted to meet specific requirements in different applications.

In hydraulic lift cylinders, the stroke length can be modified by adjusting the position of the rod or piston within the cylinder. This adjustment is typically achieved by adding or removing spacers or by using adjustable stops. By changing the effective length of the cylinder, the stroke can be increased or decreased accordingly.

The adjustment of the stroke length allows the lift cylinder to accommodate different operational needs. For example, in material handling applications, where varying load sizes are encountered, the stroke length can be adjusted to ensure that the cylinder extends or retracts precisely to the required position. This flexibility enables the lift cylinder to handle a wide range of loads and adapt to different lifting or pushing scenarios.

In addition to adjusting the stroke length, lift cylinders often incorporate position feedback mechanisms. These mechanisms, such as linear transducers or position sensors, provide real-time feedback on the actual position of the cylinder. By monitoring the position, the control system can ensure accurate and precise control over the cylinder’s movement, regardless of the stroke length.

The ability to handle variations in cylinder stroke length is crucial in many industrial applications. It allows for adaptability, efficiency, and improved performance in tasks such as material handling, assembly, and automation. By adjusting the stroke length, lift cylinders can optimize their operation, ensuring that the required force and movement are achieved consistently.

In summary, lift cylinders handle variations in cylinder stroke length through adjustable rods or pistons. This adjustment capability, combined with position feedback mechanisms, enables precise control and adaptability in different applications. By accommodating different stroke lengths, lift cylinders can effectively meet the specific requirements of a wide range of industrial tasks.

What is the importance of regular maintenance for lift cylinders?

Regular maintenance for lift cylinders is of utmost importance to ensure their optimal performance, longevity, and safe operation. Here’s an explanation of the importance of regular maintenance for lift cylinders:

1. Safety:

Regular maintenance helps identify and address potential safety issues with lift cylinders. Over time, wear and tear, leaks, or component failures can compromise the integrity and stability of the cylinder. Through regular inspections and maintenance, any safety concerns can be detected early and resolved, reducing the risk of accidents or equipment failures.

2. Performance:

Maintaining lift cylinders at regular intervals helps ensure their consistent performance. By inspecting and servicing the cylinder components, such as seals, rods, and pistons, any issues affecting the cylinder’s efficiency and functionality can be addressed. Properly maintained cylinders are more reliable, provide smoother operation, and deliver the required lifting power consistently.

3. Preventive Measures:

Regular maintenance allows for preventive measures to be taken to avoid major breakdowns or costly repairs. By following a maintenance schedule, potential problems can be identified early and resolved before they escalate. This includes tasks such as lubrication, seal replacement, cleaning, and adjusting hydraulic fluid levels, which can help extend the lifespan of the cylinder and minimize downtime.

4. Cost Savings:

Regular maintenance can lead to significant cost savings in the long run. By addressing minor issues promptly, it helps prevent major failures that require expensive repairs or cylinder replacements. Well-maintained cylinders also tend to have a longer service life, reducing the need for frequent replacements and associated costs.

5. Compliance with Manufacturer’s Recommendations:

Manufacturers often provide specific maintenance guidelines for lift cylinders. Adhering to these recommendations ensures that the cylinders are maintained according to the intended specifications. Regular maintenance helps uphold warranty requirements, maintain compliance with industry standards, and maximize the cylinder’s performance according to the manufacturer’s specifications.

6. System Efficiency:

Lift cylinders are often part of larger hydraulic systems. Regular maintenance of the cylinders helps maintain the overall efficiency of the system. Any issues or inefficiencies in the cylinders can affect the performance of the entire hydraulic system, leading to decreased productivity, increased energy consumption, and potential damage to other system components.

In summary, regular maintenance for lift cylinders is crucial for safety, performance, preventive measures, cost savings, compliance with manufacturer’s recommendations, and system efficiency. By investing in regular inspections, servicing, and adherence to maintenance schedules, lift cylinders can operate reliably, efficiently, and safely throughout their lifespan.

editor by CX 2023-10-19